Synthetic drug genotoxic impurity analysis method based on solid phase microextraction

A technology for genotoxicity and drug synthesis, applied in analytical materials, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of large matrix interference, low sensitivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] During the preparation of covalent organic framework nanospheres:

[0040] In some embodiments of the present invention, the reagents for washing the covalent organic framework nanospheres are absolute ethanol, anhydrous acetone, anhydrous dichloromethane, and absolute ethanol in sequence.

[0041] In some embodiments of the present invention, the covalent organic framework nanospheres are washed and then vacuum-dried at 40-60° C. for 10-15 hours.

Embodiment 1

[0044] Preparation of Covalent Organic Framework Nanospheres.

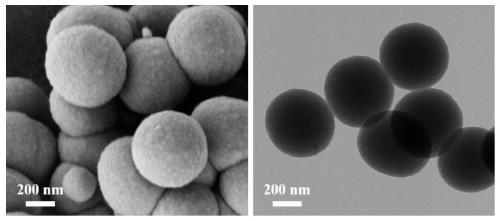

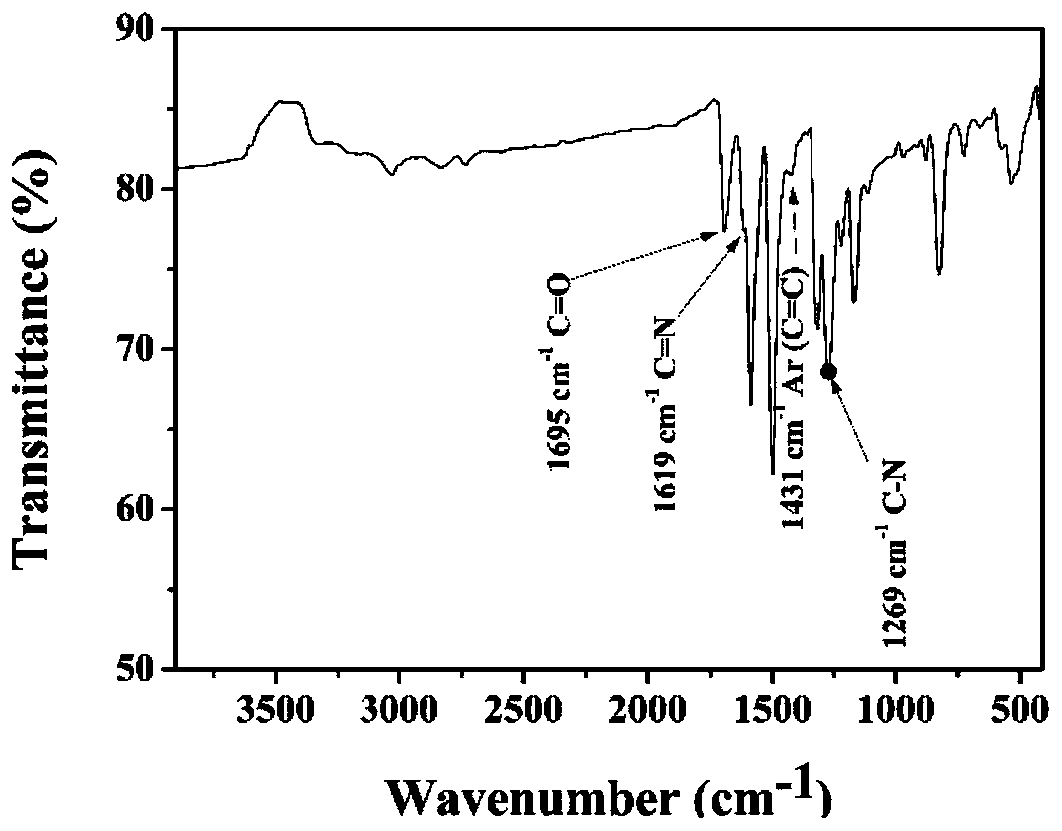

[0045] First, dilute 116.1 mg of tris-(4-aminophenyl)-amine and 130.6 mg of tris-(4-formylphenyl)-amine into 2 mL of N,N-dimethylformamide solution , the reaction solution was added to 25 mL of methanol, and stirred at room temperature for 10 minutes; then, 0.01 mL of glacial acetic acid solution was added to the solution. The above reaction solution was reacted in a water bath at 80° C. for 30 minutes. After the reaction was over, the excess reaction solution was removed, leaving a deep yellow precipitate. Finally, the precipitate was sequentially washed with absolute ethanol, anhydrous acetone, anhydrous dichloromethane, and absolute ethanol to remove residual solvents and excess raw materials remaining on the surface of the material. The washed material was vacuum dried overnight at 50 °C. The synthesized material was characterized by figure 2 It can be seen from the scanning electron microscope and the tr...

Embodiment 2

[0047] Preparation of fibers for solid-phase microextraction.

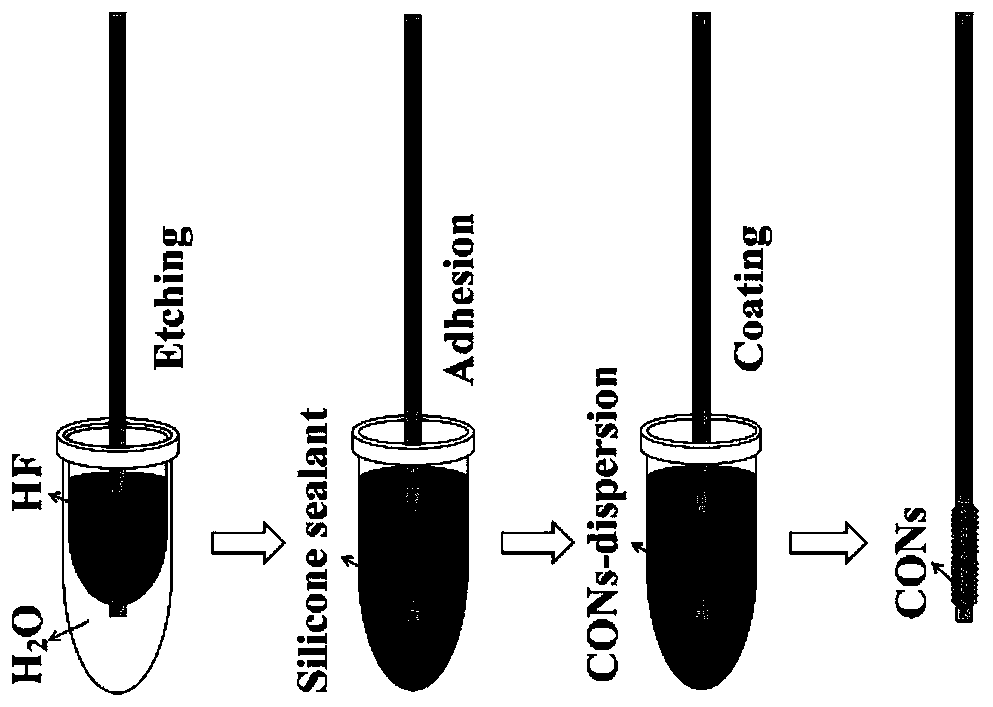

[0048] Take stainless steel fibers with a diameter of 120 microns and wash them with absolute ethanol and deionized water successively. After cleaning, the stainless steel fibers are pressed figure 1 Etching is carried out, the etching solution is hydrofluoric acid, and the etching time is 1 hour. Adhere the surface of the etched stainless steel fiber with high-temperature-resistant silicone sealant, place the treated fiber in an ethanol dispersion of covalent organic framework nanospheres (dispersion concentration is 100 mg / mL), and let it stand for one minute Take it out, the material will be evenly distributed on the surface of the stainless steel fiber. After the surface of the fiber is dry, it is aged for 3 hours under the gas chromatograph inlet, and the aging temperature is 250°C. Take it out and use it later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com