Multi-stimulus-response actuating film and preparation and application thereof

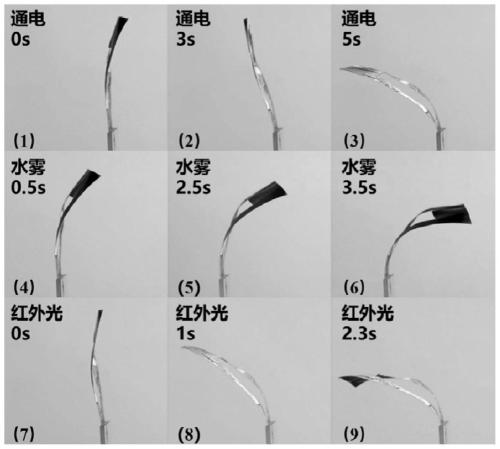

A thin film and actuation technology, which is applied in the direction of manufacturing microstructure devices, piezoelectric devices/electrostrictive devices, and processes for producing decorative surface effects, etc., can solve the problem of low film formation strength and single response stimulus conditions of actuated films and other problems, the preparation method is simple and fast, the actuation behavior is obvious, and the effect of reducing interface problems is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

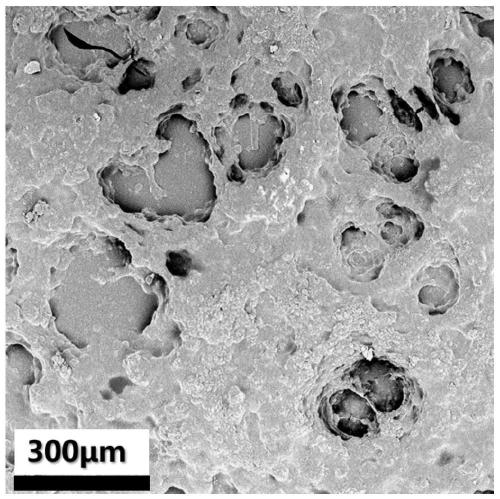

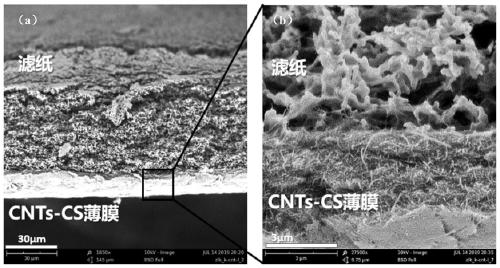

[0039] (1) At room temperature, measure 0.3 ml of acetic acid, add deionized water and dilute to 10 ml to obtain an acetic acid solution with a volume concentration of 3%, weigh 250 mg of chitosan and disperse it into a 3% acetic acid solution, heat and stir at 60 °C to obtain Chitosan dispersion, then weigh 25 mg of carbon nanotubes and add it to the chitosan dispersion, and treat it with a cell ultrasonic pulverizer in an ice-water bath for 2 hours to disperse the carbon nanotubes uniformly to obtain a carbon nanotube-chitosan dispersion. ;

[0040] (2) Pour the carbon nanotube-chitosan dispersion obtained in step (1) into a sand core funnel, and use cellulose acetate filter paper as a filter membrane to perform suction filtration through a circulating water vacuum pump. After the carbon nanotube-chitosan / acetate filter paper film was formed by suction filtration, that is, after the carbon nanotube-chitosan dispersion lost its fluidity, it was dried in a 50°C oven for 2 hour...

Embodiment 2

[0047] (1) At room temperature, measure 0.3 ml of acetic acid, add deionized water and dilute to 10 ml to obtain an acetic acid solution with a volume concentration of 3%, weigh 250 mg of chitosan and disperse it into a 3% acetic acid solution, heat and stir at 60 °C to obtain Chitosan dispersion, then weigh 35 mg of carbon nanotubes and add it to the chitosan dispersion, and treat with a cell ultrasonic pulverizer in an ice-water bath for 2 hours to disperse the carbon nanotubes uniformly to obtain a carbon nanotube-chitosan dispersion. ;

[0048] (2) Pour the carbon nanotube-chitosan dispersion obtained in step (1) into a sand core funnel, and use cellulose acetate filter paper as a filter membrane to perform suction filtration through a circulating water vacuum pump. After the carbon nanotube-chitosan / acetate fiber filter paper film was formed by suction filtration, that is, after the carbon nanotube-chitosan dispersion lost its fluidity, it was dried in a 60°C oven for 1.5...

Embodiment 3

[0050] (1) At room temperature, measure 0.3 ml of acetic acid, add deionized water and dilute to 10 ml to obtain an acetic acid solution with a volume concentration of 3%, weigh 250 mg of chitosan and disperse it into a 3% acetic acid solution, heat and stir at 60 °C to obtain Chitosan dispersion, then weigh 45 mg of carbon nanotubes and add it to the chitosan dispersion, and treat it with a cell ultrasonic pulverizer in an ice-water bath for 2 hours to disperse the carbon nanotubes uniformly to obtain a carbon nanotube-chitosan dispersion. ;

[0051] (2) Pour the carbon nanotube-chitosan dispersion obtained in step (1) into a sand core funnel, and use cellulose acetate filter paper as a filter membrane to perform suction filtration through a circulating water vacuum pump. After the carbon nanotube-chitosan / acetate fiber filter paper film is formed by suction filtration, that is, after the carbon nanotube-chitosan dispersion loses its fluidity, it is dried in a 70°C oven for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com