Lamellar MWW molecular sieve as well as preparation method and application thereof

A technology of molecular sieves and sheets, applied in the field of molecular sieves, can solve the problems of low utilization rate of active sites, easy carbon deposition and deactivation, etc., and achieve the effect of improving the conversion rate of benzyl alcohol, increasing the external area, and reducing carbon deposition and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

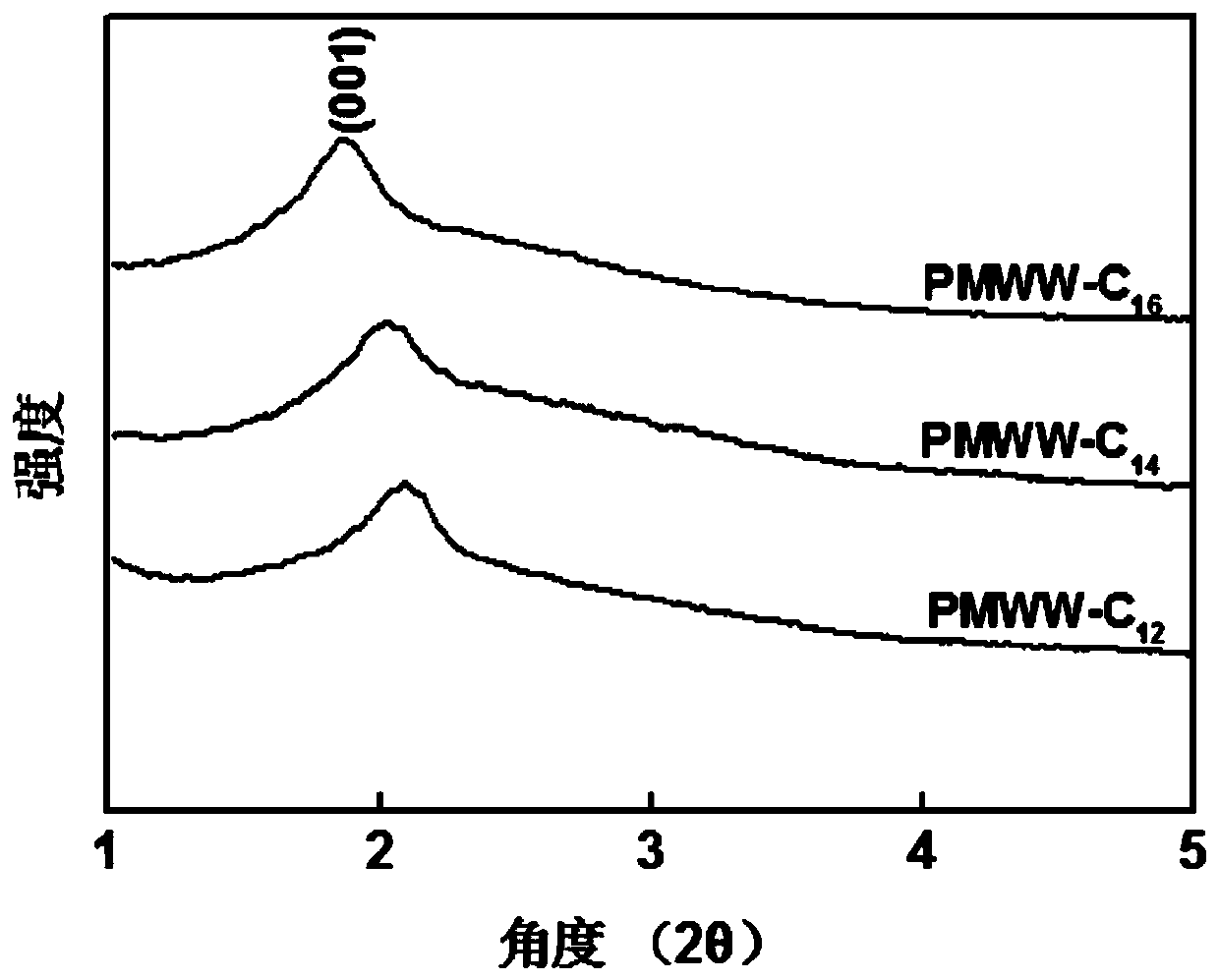

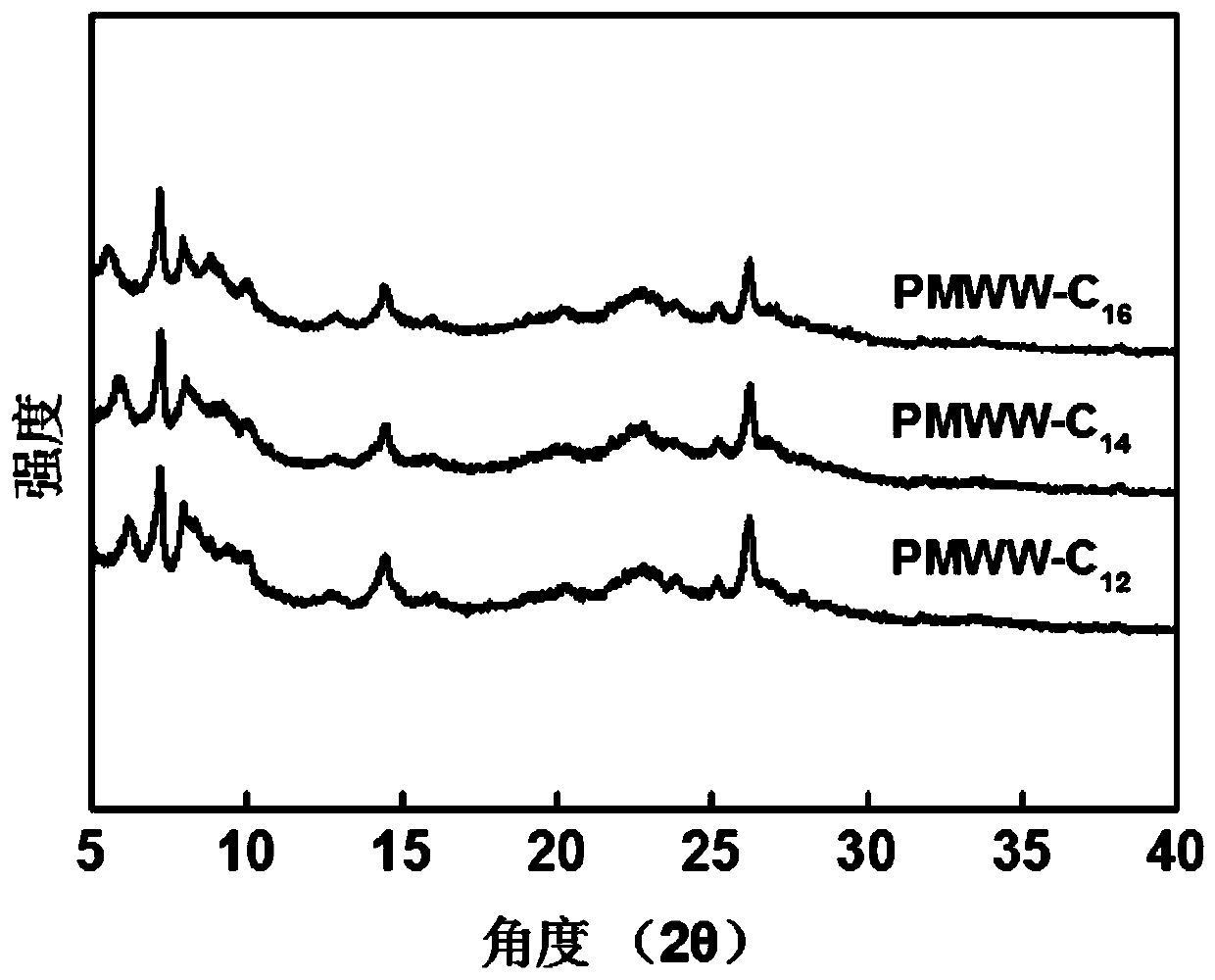

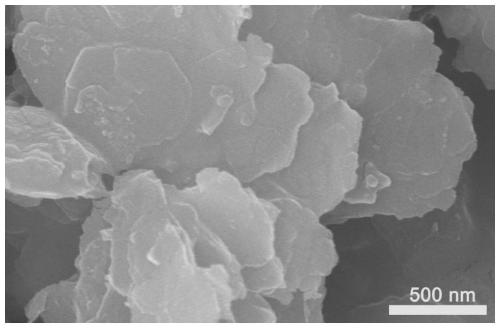

Embodiment 1

[0048] This embodiment carries out the preparation of sheet MWW molecular sieve, comprises the following steps:

[0049] 1) Weigh 0.072g of sodium aluminate and 0.248g of sodium hydroxide and dissolve in 31.1g of deionized water, stir to dissolve, then add 1.91g of hexamethyleneimine and 2.36g of fumed silica, and stir magnetically at room temperature After 5 hours, it was transferred to a polytetrafluoroethylene bottle and crystallized for 11 days in a homogeneous reactor at 135° C. with a rotational speed of 8 rpm / min. After the crystallization was completed, the crystallized product was filtered, washed repeatedly with deionized water, and dried overnight in a drying oven at 100° C. to obtain the first product.

[0050]2) Weigh 9g of the aqueous solution containing 20wt% of the first product, mix it with 35.0g of 29wt% dodecyltrimethylammonium bromide aqueous solution and 11.0g of 40wt% tetrapropylammonium hydroxide aqueous solution, and react with magnetic stirring at room...

Embodiment 2

[0054] In this example, the preparation of sheet-layer MWW molecular sieves is carried out. The steps of this example are the same as in Example 1, except that the aqueous solution of dodecyltrimethylammonium bromide is replaced by aqueous solution of tetradecyltrimethylammonium bromide to obtain Sheet MWW molecular sieve PMWW-C14.

Embodiment 3

[0056] This embodiment carries out the preparation of sheet-layer MWW molecular sieve, and this embodiment is the same as embodiment 1 step, and the difference is that dodecyltrimethylammonium bromide aqueous solution is replaced by hexadecyltrimethylammonium bromide aqueous solution, obtains Sheet MWW molecular sieve PMWW-C16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com