A high-efficiency biological treatment system and process for organic nitrogen industrial wastewater

A technology for industrial wastewater and biological treatment, applied in biological water/sewage treatment, electrochemical biological combination treatment, water/sludge/sewage treatment, etc. Removal of low efficiency and other problems, to achieve the effect of improving microbial denitrification ability, biodegradability, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

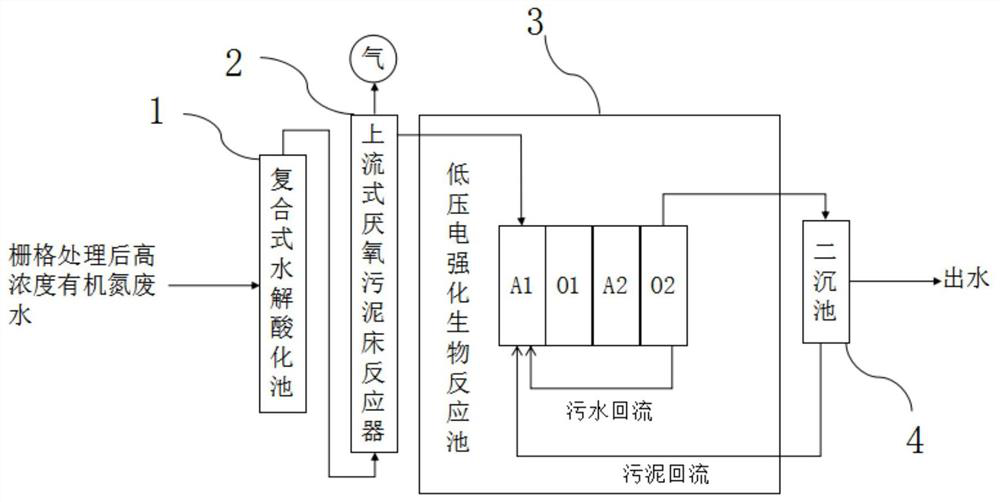

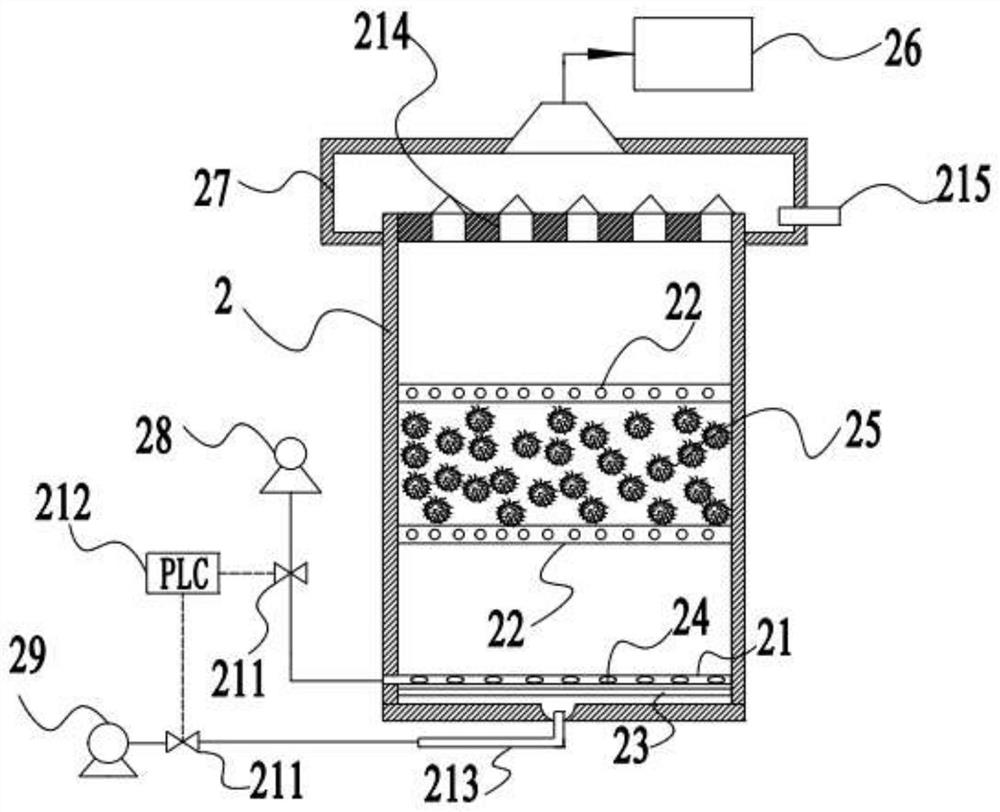

[0035] This embodiment adopts a set of small-scale test equipment with a processing capacity of 10L / d. The organic nitrogen industrial wastewater treated is taken from the effluent of a textile printing and dyeing factory. The average value is 150mg / L, and the average value of COD concentration is 2300mg / L. The wastewater treatment process is as follows figure 1 As shown, it includes a compound hydrolytic acidification tank 1, an upflow anaerobic sludge bed filter 2, a low-voltage electric enhanced biological reaction tank 3 and a secondary sedimentation tank 4 connected in series.

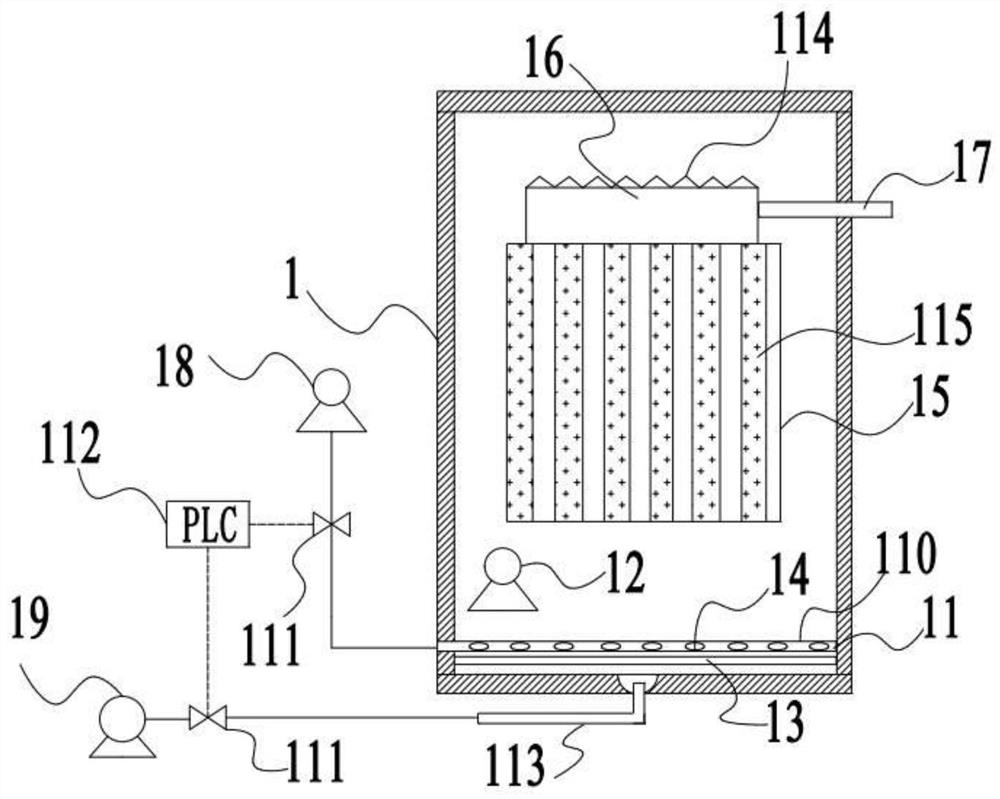

[0036] Such as figure 2 As shown, the bottom of the composite hydrolytic acidification tank 1 is provided with a multi-point water distribution system-11, a submersible pump 12 and a mud discharge device-13, wherein the multi-point water distribution system-11 includes a The bottom has a water distribution pipe 110 with multiple water distribution holes 14, the distance between the water inlet ...

Embodiment 2

[0043] This embodiment adopts the same test scope as that of Example 1, that is, adopts a set of small test equipment, the same processing system, and a processing capacity of 4 L / d. The difference with Example 1 is that the processed organic nitrogen industrial wastewater is taken from the production wastewater of a certain pharmaceutical factory. The water quality characteristics include that the average value of total nitrogen concentration is 83mg / L, the average concentration of organic nitrogen is 432mg / L, and the average value of COD concentration is 10300mg / L, the system process flow chart is as follows figure 1 As shown, the process of wastewater treatment by this system includes the following steps:

[0044] Step 1: The organic nitrogen industrial wastewater is treated by the grid; it is controlled by the multi-point water distribution system 11 to enter the compound hydrolysis acidification tank 1, and the pH in the control tank is 8.0, the hydraulic retention time i...

Embodiment 3

[0048] This embodiment adopts the same test range as that of Example 1, that is, adopts a set of small-scale test equipment, the same processing system, and a processing capacity of 5 L / d. The difference from Example 1 is that the processed organic nitrogen industrial wastewater is organic amine wastewater, and the water quality characteristics include an average total nitrogen concentration of 1300 mg / L, an average organic nitrogen concentration of 520 mg / L, and an average COD concentration is 17000mg / L, the system process flow chart is as follows figure 1 As shown, the process of wastewater treatment by this system includes the following steps:

[0049] Step 1: The organic nitrogen industrial wastewater is treated by the grid; it is controlled by the multi-point water distribution system 11 to enter the compound hydrolysis acidification tank 1, and the pH in the control tank is 8.0, the hydraulic retention time is 10h, and the sludge concentration is 5.2g / L-6.0g / L, the slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com