Acrylic chlorine fiber textile and its production method

A production method and textile technology, applied in textiles and papermaking, liquid-repellent fibers, plant fibers, etc., can solve the problems of water and oil repellency decline, oil repellency decline, etc., and achieve good water and oil repellency, The effect of excellent water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] In the preparation step of the water and oil repellent finishing liquid, the raw materials including the water and oil repellent agent, the crosslinking agent, the organic solvent and acetic acid are mixed to obtain the water and oil repellent finishing liquid. The concentration of water and oil repellent in the water and oil repellent finishing liquid is 100~150g / L, the concentration of crosslinking agent is 10~25g / L, the concentration of organic solvent is 3~8g / L, and the concentration of acetic acid is 0.2~2g / L .

[0076] The water and oil repellent agent of the present invention can be prepared by the following steps: (1) pre-emulsification step; (2) intermediate reaction step; (3) final reaction step.

[0077] In step (1), perfluoroalkyl ethyl (meth) acrylate, C15-C25 alkyl (meth) acrylate, (meth) acrylate containing isocyanate, molecular weight regulator, iso Alcohol polyoxyethylene ether, C6-C25 alkyl polyoxyethylene ether, propylene glycol condensate and water ...

preparation example 1~3 and

[0094] Preparation Examples 1-3 and Preparation Comparative Example 1-Preparation of Water and Oil Repellent Agent

[0095] (1) According to the formula in Table 1, perfluorooctyl ethyl acrylate, stearyl acrylate, isocyanate-containing (meth)acrylate (methacrylic acid-2-isocyanatoethyl 3, 5-dimethylpyrazole adduct), n-dodecyl mercaptan, isomeric alcohol polyoxyethylene ether (isomeric tridecyl polyoxyethylene ether (20)), cetyl polyoxyethylene ( 20) Ether, propylene glycol condensate (dipropylene glycol) and water are mixed in a high-pressure homogenizer, and then pre-emulsified to obtain a pre-emulsion.

[0096] (2) Mix the pre-emulsion, vinyl chloride and azobisisobutyronitrile in a pressure-resistant reactor under a nitrogen atmosphere, and react at 70° C. for 6 hours to obtain an intermediate product.

[0097] (3) Reduce the pressure of the pressure-resistant reactor to a relative vacuum of -0.5 MPa, lower the temperature to 25° C., and react for 20 minutes to obtain a ...

Embodiment 1~7 and comparative example 1~3

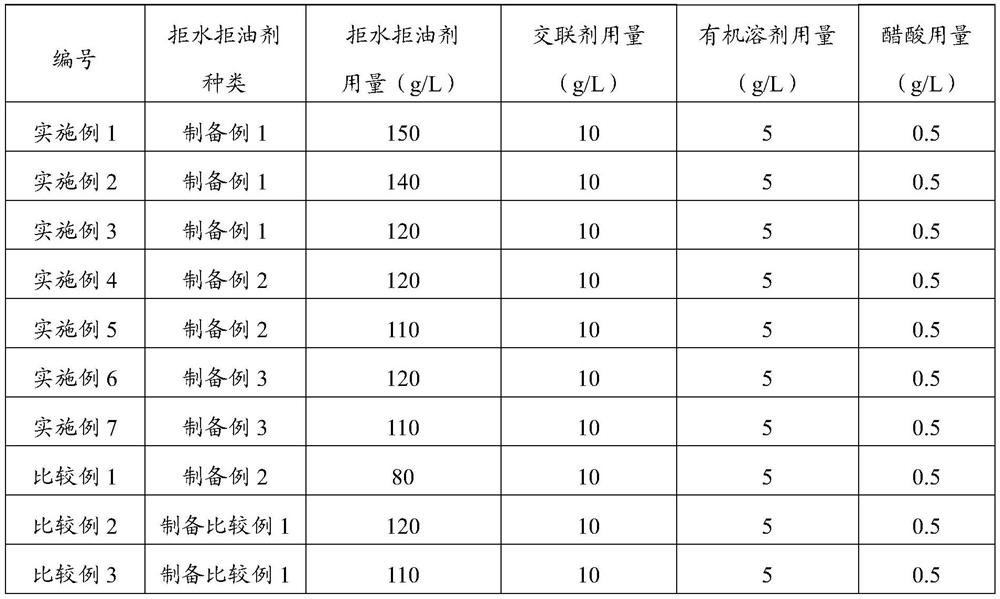

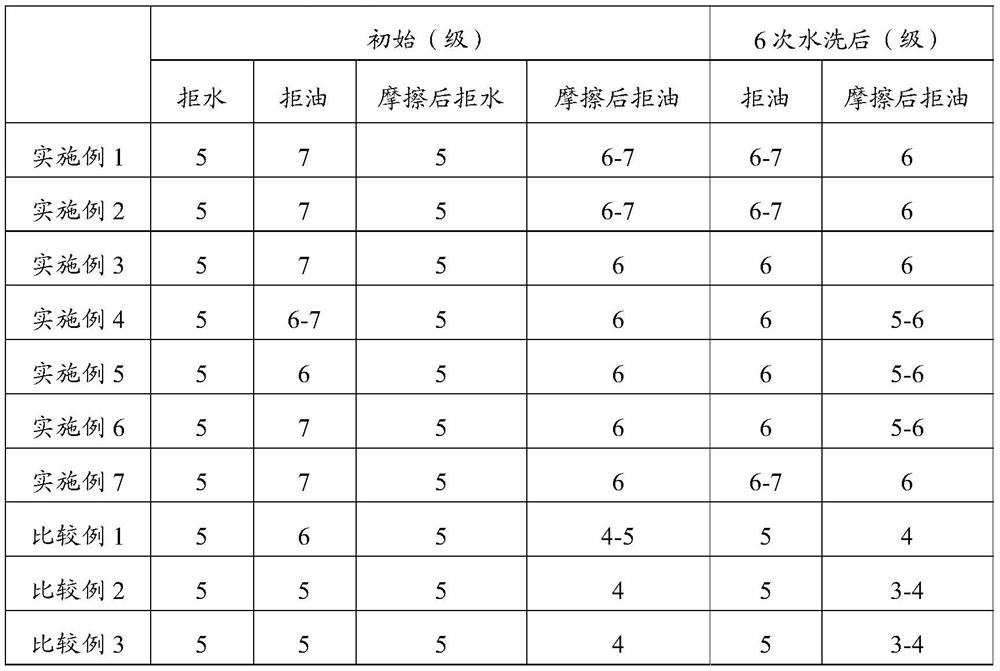

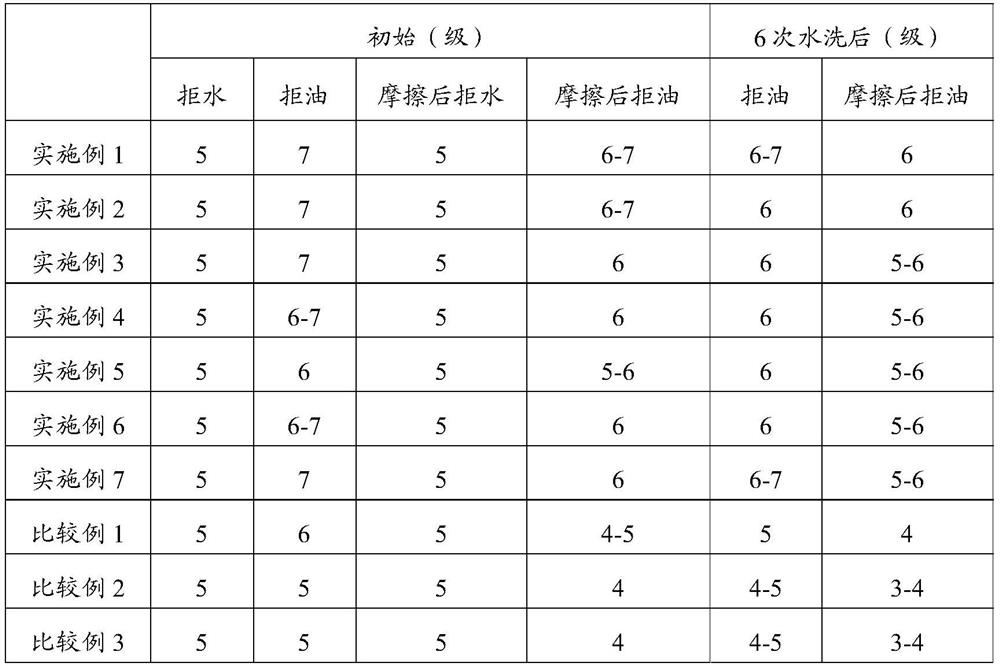

[0102] Examples 1-7 and Comparative Examples 1-3-water and oil repellent finishing liquid

[0103] According to the formula in Table 2, water and oil repellent agent, crosslinking agent (melamine resin crosslinking agent, BECKAMINE M3 of DIC company), organic solvent (isopropanol), acetic acid and water are mixed to obtain water and oil repellent finishing liquid .

[0104] The acrylic-chlorofiber textile to be finished is subjected to padding treatment with a water-repellent and oil-repellent finishing solution, and then dried and baked to obtain the acrylic-chlorofiber textile. The padding method is two dipping and two rolling, and the excess rolling rate is 62%. The drying temperature is 120°C, and the drying time is 120s. The baking temperature is 160°C, and the baking time is 180s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com