Coating emulsion composition, and water/oil-repellent paper and making method

a technology of water/oil repellency paper and composition, applied in papermaking, transportation and packaging, bandages, etc., can solve the problems of difficult to provide a sufficient level fold-up portions suffer noticeable loss of etc., to and improve water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0024]Described below are components in the coating emulsion composition according to the first embodiment of the invention.

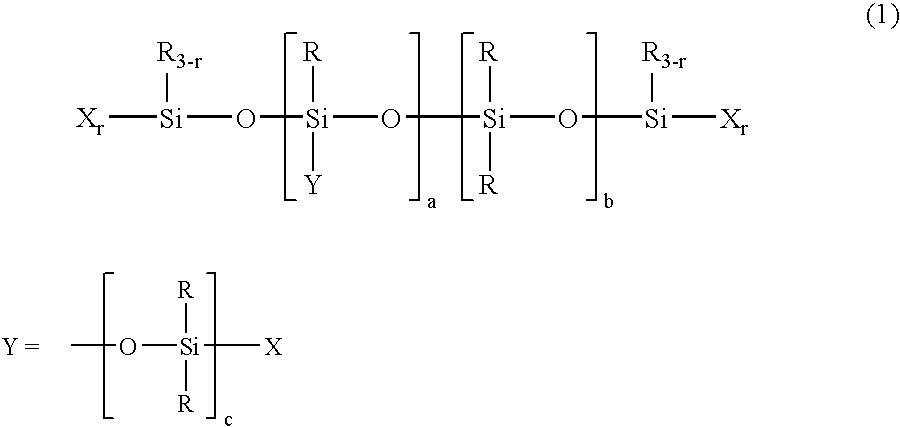

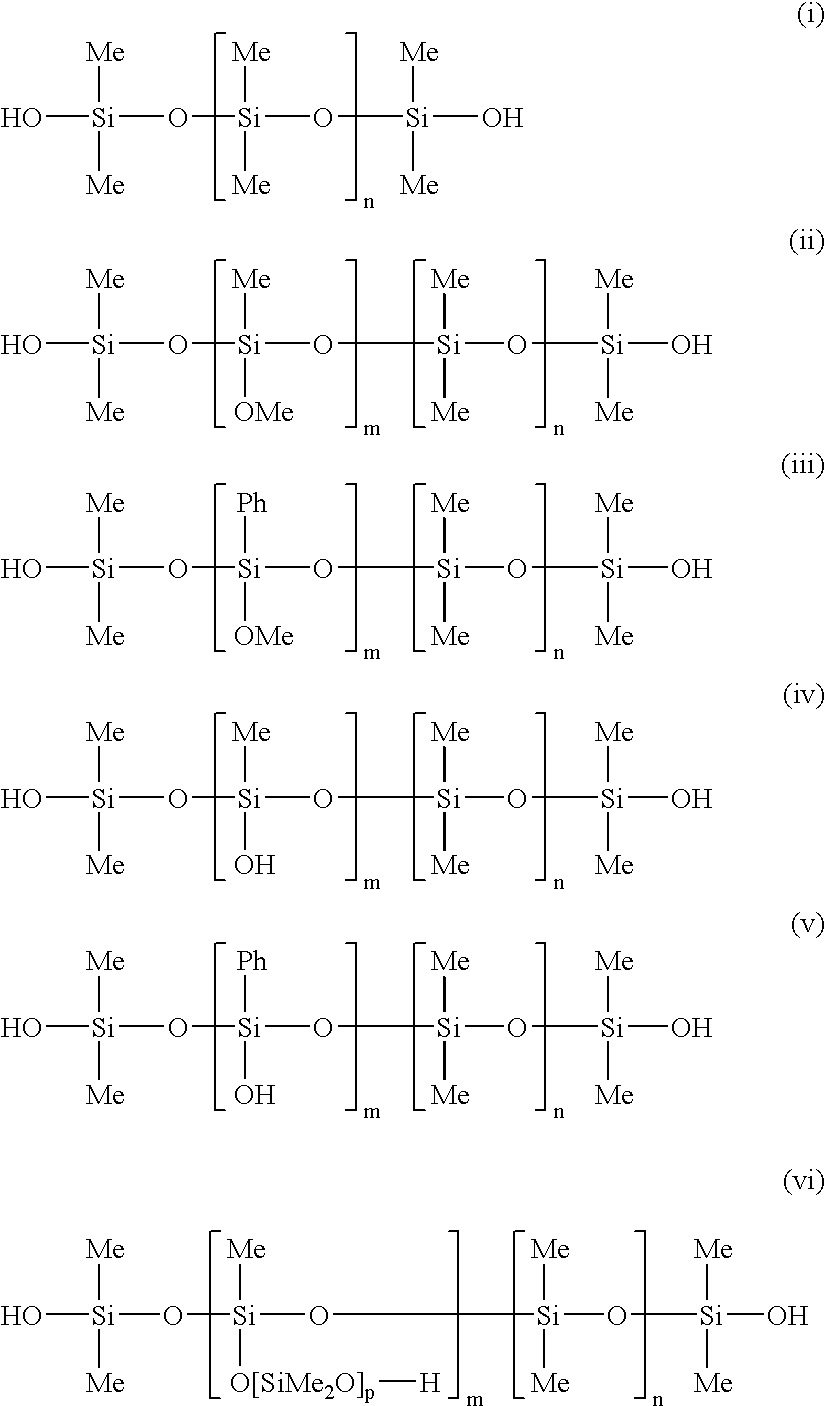

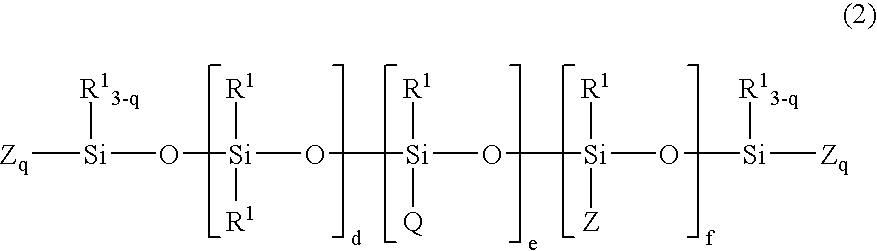

[0025]Component (A) is an organopolysiloxane containing at least two silicon-bonded hydroxyl groups in a molecule, and typically an organopolysiloxane having the average compositional formula (1):

Herein R is each independently a C1-C20 alkyl group or a C6-C20 aryl group. X is each independently a C1-C20 alkoxy group or a hydroxyl group, with the proviso that at least two X's are hydroxyl groups. The subscript “a” is 0 or a positive number of 0<a≦1,000, “b” is a positive number of 100≦b≦10,000, “c” is 0 or a positive number of 0<c≦1,000, 100≦axc+b≦100,000, and r is 1, 2 or 3.

[0026]Specifically, R is each independently selected from C1-C20 alkyl groups and C6-C20 aryl groups, for example, chain-like alkyl groups such as methyl, ethyl, propyl, butyl, pentyl, hexyl, heptyl, octyl, nonyl, decyl, dodecyl, tetradecyl, hexadecyl, and octadecyl, cycloalkyl groups such a...

second embodiment

[0056]Next, the water- and oil-repellent paper sheet according to the second embodiment of the invention is described.

[0057]The water- and oil-repellent paper sheet includes a water- and oil-repellent, releasable silicone resin layer on at least one surface of a paper substrate.

[0058]The paper substrate used herein is not particularly limited. A choice of paper may be made depending on a particular application as long as a silicone resin layer can be formed on at least one surface thereof. Suitable paper substrates include kraft paper, wood-free paper, paper board, liner, glassine paper, and parchment paper. The fibrous material of which the paper substrate is made is not limited to cellulose and cellulose derivatives. Also, instead of paper substrates, woven fabrics and non-woven fabrics comprising fibers derived from raw materials other than cellulose and cellulose derivatives may be used as the substrate.

[0059]The silicone resin layer or coating has not only good water repellency...

synthesis example 1

[0089]A 2-L polyethylene beaker was charged with 498 g of octamethylcyclotetrasiloxane, 2 g of triethoxyphenylsilane, 50 g of 10% sodium laurylsulfate aqueous solution, and 50 g of 10% dodecylbenzenesulfonic acid aqueous solution. Using a homomixer, the components were emulsified uniformly, after which 400 g of water was slowly added for dilution. This was passed two times through a high-pressure homogenizer under a pressure of 30 MPa, obtaining a uniform white emulsion. The emulsion was transferred to a 2-L glass flask equipped with an agitator, thermometer, and reflux condenser where polymerization reaction was effected at 50° C. for 24 hours. It was allowed to mature at 10° C. for 24 hours before it was neutralized to pH 6.2 with 12 g of 10% sodium carbonate aqueous solution. This emulsion had a nonvolatile content of 45.4% after drying at 105° C. for 3 hours and contained an organopolysiloxane in a non-flowing soft gel form which had the average compositional formula shown below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| humidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com