High-nickel quaternary lithium ion battery material Li-Ni-Co-Mn-Mo-O and preparation method thereof

A li-ni-co-mn-mo-o, lithium-ion battery technology, applied in the field of lithium-ion battery cathode materials, can solve the problems of unfavorable long-term large-scale use, use of battery materials, poor rate performance, etc., and achieve favorable Long-term large-scale use, reduction of environmental problems, and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

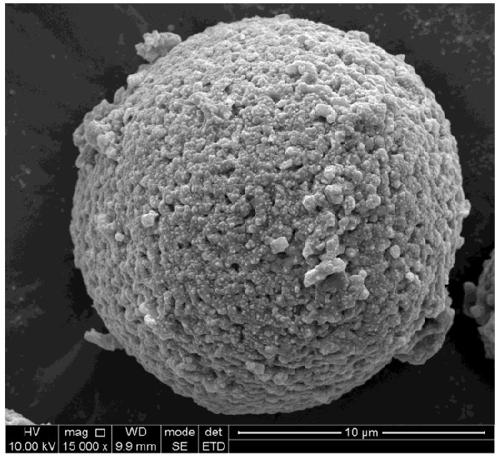

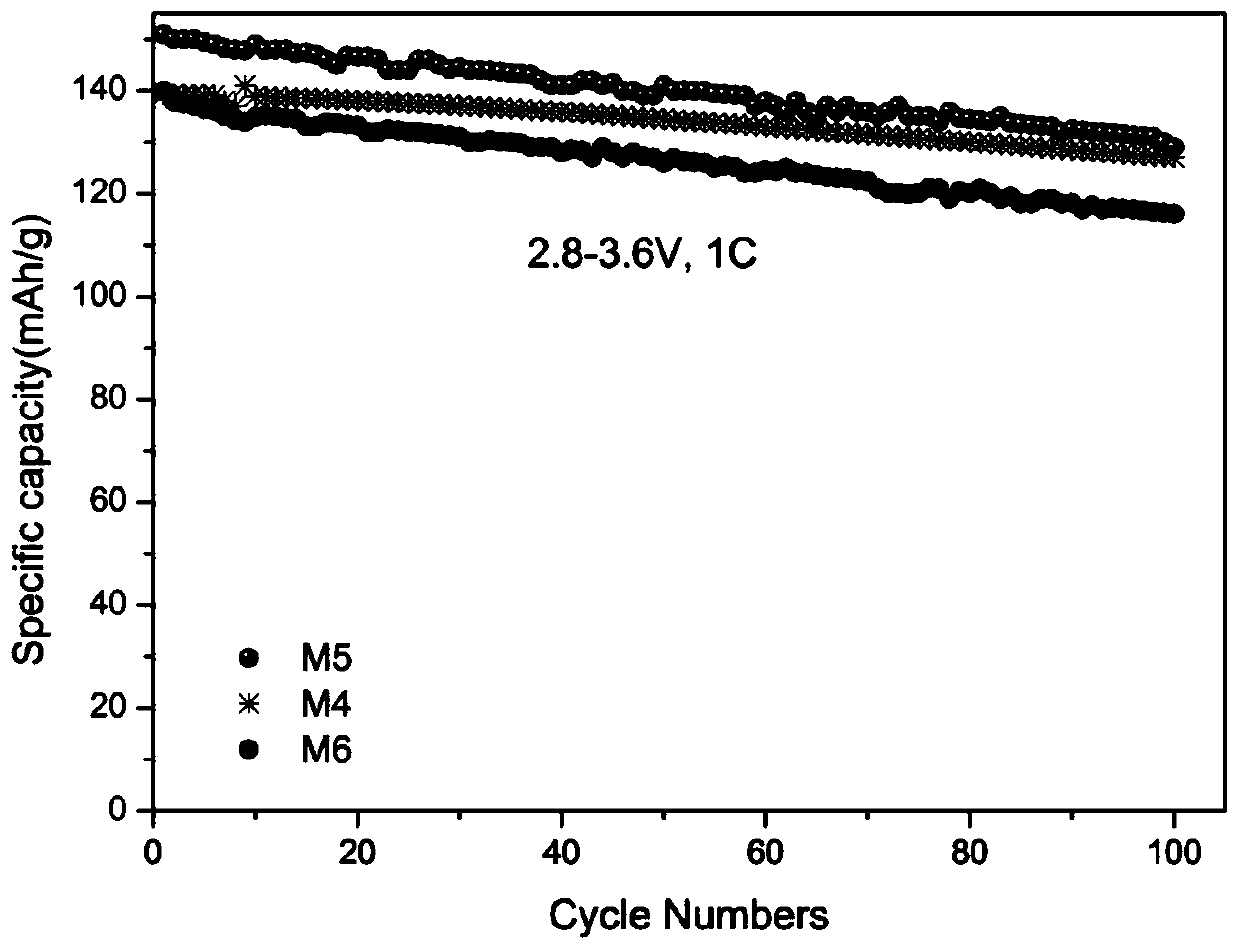

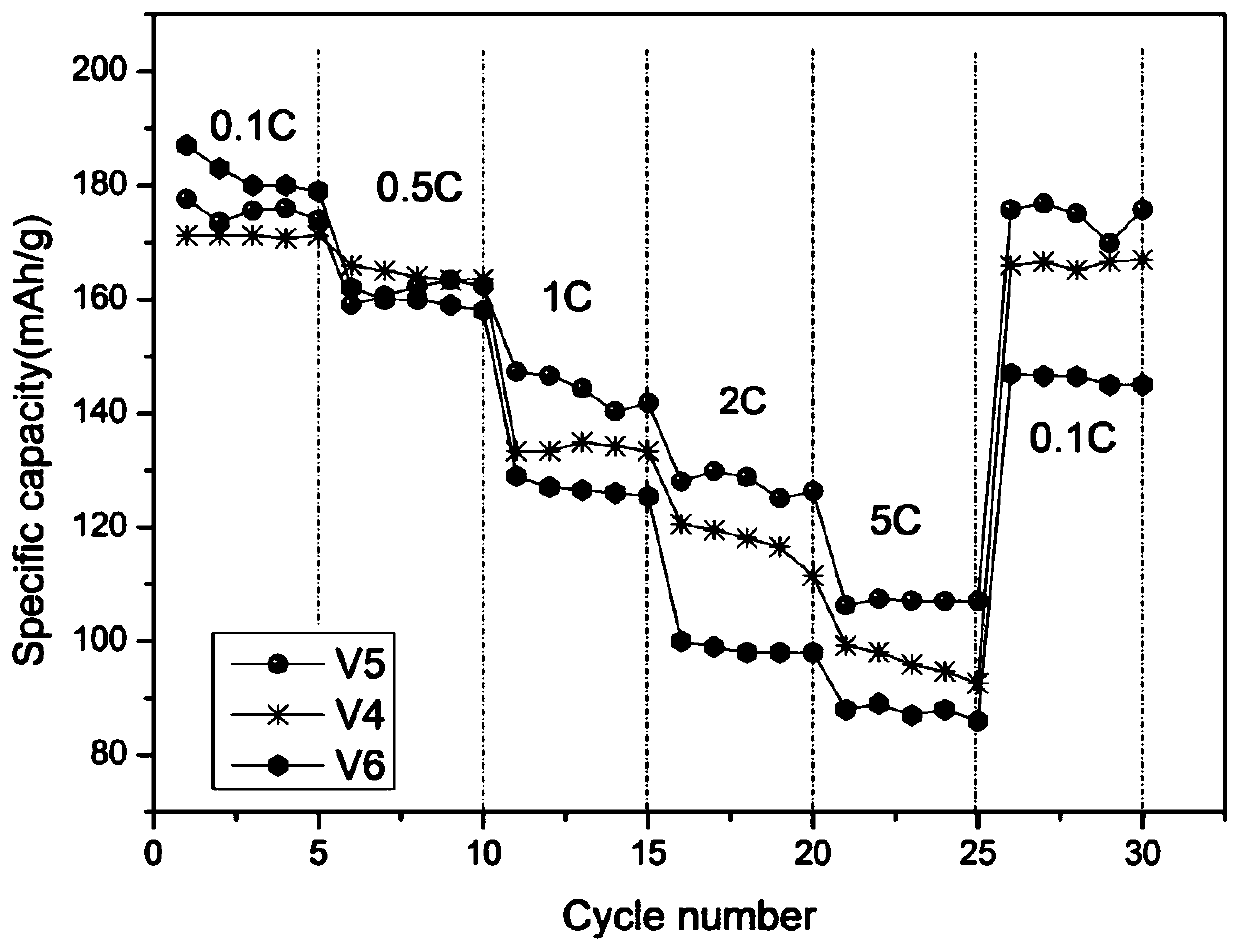

Image

Examples

Embodiment 1

[0028] The preparation method of the quaternary lithium ion battery material Li-Ni-Co-Mn-Mo-O of the present embodiment comprises the following steps:

[0029] (1) Calculate and weigh 14.928g of nickel acetate, 3.984g of cobalt acetate, and 4.900g of manganese acetate in deionized water to form 0.8mol / L metal ion solution; at the same time, add 4.943g ammonium heptamolybdate (tetrahydrate) into a small amount of deionized water to fully dissolve;

[0030] (2) Ammonium heptamolybdate solution is beaten into the mixed solution of nickel acetate, cobalt acetate and manganese acetate with a peristaltic pump, and is configured into a quaternary metal ion solution of 0.6mol / L;

[0031] (3) 13.86g oxalic acid is added into deionized water, and is configured into a 0.6mol / L oxalic acid solution;

[0032] (4) With oxalic acid solution as the bottom liquid, add the quaternary metal ion solution to the oxalic acid solution at a rate of 7mL / min for stirring and mixing, the stirring rate ...

Embodiment 2

[0036] The preparation method of the quaternary lithium ion battery material Li-Ni-Co-Mn-Mo-O of the present embodiment comprises the following steps:

[0037] (1) Calculate and weigh 14.928g of nickel acetate, 3.735g of cobalt acetate, and 4.900g of manganese acetate in deionized water to form 0.8mol / L metal ion solution; at the same time, add 6.179g ammonium heptamolybdate (tetrahydrate) into a small amount of deionized water to fully dissolve;

[0038] (2) Ammonium heptamolybdate solution is beaten into the mixed solution of nickel acetate, cobalt acetate and manganese acetate with a peristaltic pump, and is configured into a quaternary metal ion solution of 0.6mol / L;

[0039] (3) Add 13.86g (10% excess to ensure that all metal ions are precipitated) oxalic acid into deionized water, and configure it into a 0.6mol / L oxalic acid solution;

[0040] (4) With oxalic acid solution as the bottom liquid, add the quaternary metal ion solution to the oxalic acid solution at a rate ...

Embodiment 3

[0044] (1) Calculate and weigh 14.928g of nickel acetate, 3.486g of cobalt acetate, and 4.900g of manganese acetate in deionized water to form 0.8mol / L metal ion solution; at the same time, add 7.415g ammonium heptamolybdate (tetrahydrate) into a small amount of deionized water to fully dissolve;

[0045] (2) Ammonium heptamolybdate solution is beaten into the mixed solution of nickel acetate, cobalt acetate and manganese acetate with a peristaltic pump, and is configured into a quaternary metal ion solution of 0.6mol / L;

[0046] (3) Add 13.86g (10% excess to ensure that all metal ions are precipitated) oxalic acid into deionized water, and configure it into a 0.6mol / L oxalic acid solution;

[0047] (4) With oxalic acid solution as the bottom liquid, add the quaternary metal ion solution to the oxalic acid solution at a rate of 7mL / min for stirring and mixing, the stirring rate is 550rpm, the temperature is 50°C, the pH is 6.5 (controlled by ammonia water), the reaction time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com