Sugar-free plant yoghourt and preparation method thereof

A technology of yogurt and plants, applied in the direction of bacteria used in food preparation, dairy products, food science, etc., can solve the problems of bad taste of plant-based yogurt, and achieve good taste, low glycemic index, healthy taste and low energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also discloses a method for preparing the aforementioned sugar-free vegetable yoghurt, which includes the following steps:

[0027] Step 1. Select raw materials according to the weight ratio, mix the raw materials: soybean milk, walnut milk, coconut milk, xylitol, mixed sugar alcohols, steviol glycosides, resistant dextrin and inulin, add pure water and stir to obtain a mixed slurry , the mixed slurry is finely ground and homogenized at normal temperature, and the ground mixed slurry is centrifuged to remove slag through a sieve, and is pasteurized to obtain liquid A.

[0028] Step 2. Under sterile conditions, add 0.5-2.5% of the mass of liquid A prepared in step 1 into Lactobacillus bulgaricus, Streptococcus thermophilus or Lactococcus lactis diacetyl subspecies and ferment at 38-45°C for 7-10 hours to form pure vegetable yogurt.

[0029] Step 3: Take the pure vegetable raw yogurt prepared in Step 2, add a stabilizer with a mass ratio of 0.5-0.8%...

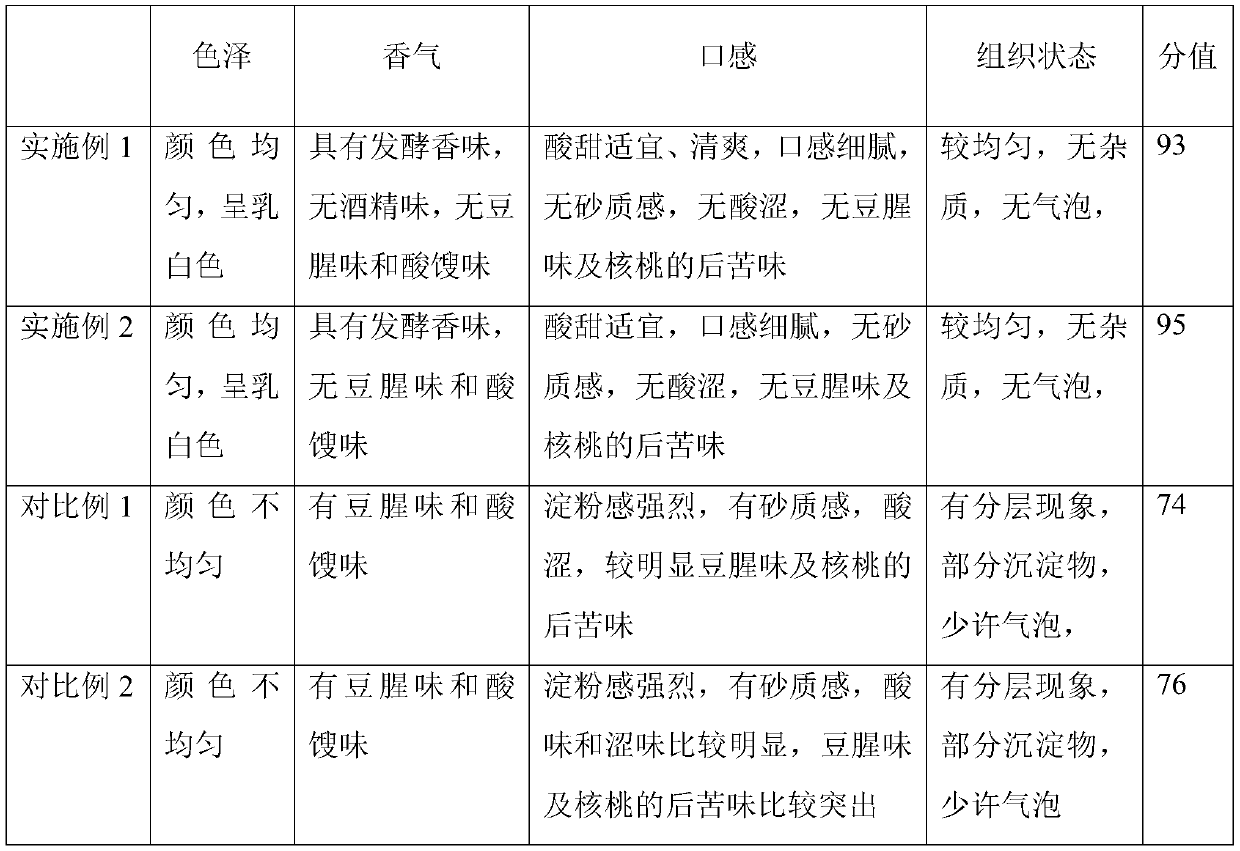

Embodiment 1

[0048] The preparation method of the first sugar-free vegetable yoghurt of the present invention comprises the following steps:

[0049] Step (31), choose 20 parts of soybean milk, 25 parts of walnut milk, 20 parts of coconut milk, 5 parts of xylitol, 1 part of maltitol, 0.1 part of steviol glycoside, 8 parts of resistant dextrin and 32 parts of inulin, add 10 parts of purified water were finely ground and homogenized at room temperature, and the ground slurry was centrifuged through a sieve to remove slag, and pasteurized to obtain liquid A1.

[0050] Step (32), under aseptic conditions, add 0.5% of the mass of the liquid A1 prepared in step (31) to Lactobacillus bulgaricus, Streptococcus thermophilus or Lactococcus lactis diacetyl subspecies and ferment at 38°C for 10 hours , to form pure vegetable yoghurt.

[0051] Step (33), take the pure vegetable raw yoghurt prepared in step (32), add pectin and 0.2 part of carrageenan in mass ratio as stabilizers, blend and mix in the ...

Embodiment 2

[0053] The preparation method of the second sugar-free vegetable yoghurt of the present invention comprises the following steps:

[0054] Step (41), select 10 parts of soybean milk, 20 parts of walnut milk, 25 parts of coconut milk, 4 parts of xylitol, 2.5 parts of erythritol, 0.5 part of steviol glycoside, 4 parts of resistant dextrin and 6 parts of inulin as raw materials , adding 20 parts of pure water, finely grinding and homogenizing at normal temperature, the ground slurry is centrifuged to remove slag through a sieve, and pasteurized to obtain liquid A2.

[0055] Step (42), under sterile conditions, add Lactobacillus bulgaricus, Streptococcus thermophilus or Lactococcus lactis diacetyl subspecies to 2% of the mass of liquid A2 prepared in step (41) and ferment for 10 hours at 42°C , to form pure vegetable yoghurt.

[0056] Step (43), taking the pure vegetable raw yogurt prepared in step (42), adding 0.4 parts of pectin, 0.2 parts of carrageenan and 0.2 parts of modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com