Greek yoghourt ice cream chocolate bar and preparation method thereof

The technology of Greek yogurt and chocolate is applied in the field of Greek yogurt ice cream chocolate bar and its preparation, which can solve the problems of high gastrointestinal irritation and low nutritional value, and achieve the effects of dense taste, uniform flavor and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

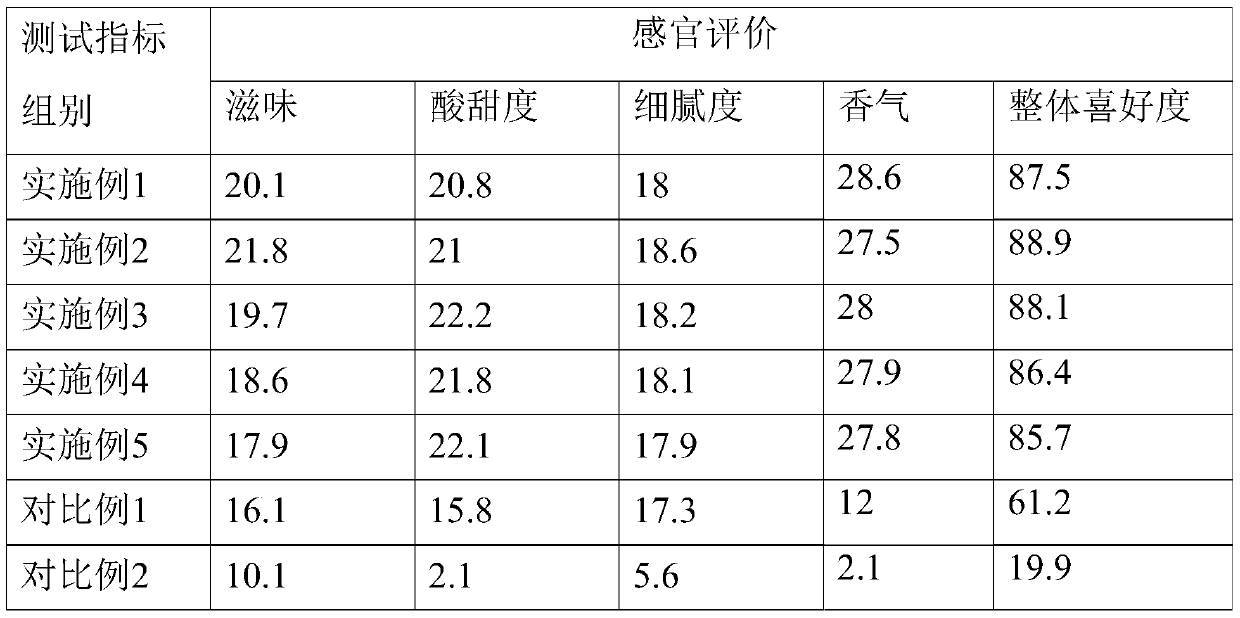

Examples

Embodiment 1

[0042] A Greek yogurt ice cream chocolate bar, comprising the following raw materials in percentage by weight: 45% of plain Greek yogurt, 0.65% of monoglyceride fatty acid, 0.5% of sodium caseinate, 0.5% of phospholipid, 0.2% of dipotassium hydrogen phosphate, carboxymethyl Sodium cellulose 0.15%, milk 39%, white sugar 5%, hazelnuts 4%, chocolate syrup 5%.

[0043] The preparation method of above-mentioned Greek yogurt ice cream chocolate bar comprises the following steps:

[0044] (1) Prepare plain Greek yogurt

[0045] ①Clean milk: Raw milk is inspected at the factory, cleaned, cooled, and raw milk is obtained;

[0046] ②Centrifugal degreasing of raw milk;

[0047] ③Primary homogenization and pasteurization: preheat the degreased raw milk to 65°C for primary homogenization, the homogenization pressure is 20MPa, and then pasteurize, the sterilization temperature is 95°C, and the sterilization time is 5 minutes;

[0048] ④ Inoculation and fermentation: After pasteurization,...

Embodiment 2

[0056] A Greek yogurt ice cream chocolate bar, comprising the following raw materials in percentage by weight: 55% of plain Greek yogurt, 0.65% of monoglyceride fatty acid, 0.5% of sodium caseinate, 0.5% of phospholipid, 0.2% of dipotassium hydrogen phosphate, carboxymethyl Sodium cellulose 0.15%, milk 29%, white sugar 5%, hazelnuts 4%, chocolate syrup 5%.

[0057] The preparation method of above-mentioned Greek yogurt ice cream chocolate bar comprises the following steps:

[0058] (1) Prepare plain Greek yogurt

[0059] ①Clean milk: Raw milk is inspected at the factory, cleaned, cooled, and raw milk is obtained;

[0060] ②Centrifugal degreasing of raw milk;

[0061] ③Primary homogenization and pasteurization: preheat the degreased raw milk to 65°C for primary homogenization, the homogenization pressure is 20MPa, and then pasteurize, the sterilization temperature is 95°C, and the sterilization time is 5 minutes;

[0062] ④ Inoculation and fermentation: After pasteurization,...

Embodiment 3

[0070] A Greek yogurt ice cream chocolate bar, comprising the following raw materials in percentage by weight: 50% of plain Greek yogurt, 0.65% of monoglyceride fatty acid, 0.5% of sodium caseinate, 0.5% of phospholipid, 0.2% of dipotassium hydrogen phosphate, carboxymethyl Sodium cellulose 0.15%, milk 29%, white sugar 3%, white peach jam 4%, chocolate pulp 10%.

[0071] When the flavor modifier is jam, it is not necessary to add the flavor modifier to the outer layer of the chocolate, but to add it when preparing the finished ice cream. The flavor modifier in this recipe is white peach jam, and the timing is to add it when preparing the semi-finished ice cream That is to mix with plain Greek yogurt and colloidal feed liquid.

[0072] The preparation method of above-mentioned Greek yogurt ice cream chocolate bar comprises the following steps:

[0073] (1) Prepare plain Greek yogurt

[0074] ①Clean milk: Raw milk is inspected at the factory, cleaned, cooled, and raw milk is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com