Processing method and device of coarse cereal and nut nutritional composite paste food

A compound paste and processing device technology, applied to the functions of food ingredients, cleaning methods using liquids, food ingredients as antimicrobial preservation, etc., can solve the problems of non-caking nutrition, incompleteness, etc., and achieve the prevention of arteriosclerosis , increase the elasticity of blood vessels, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

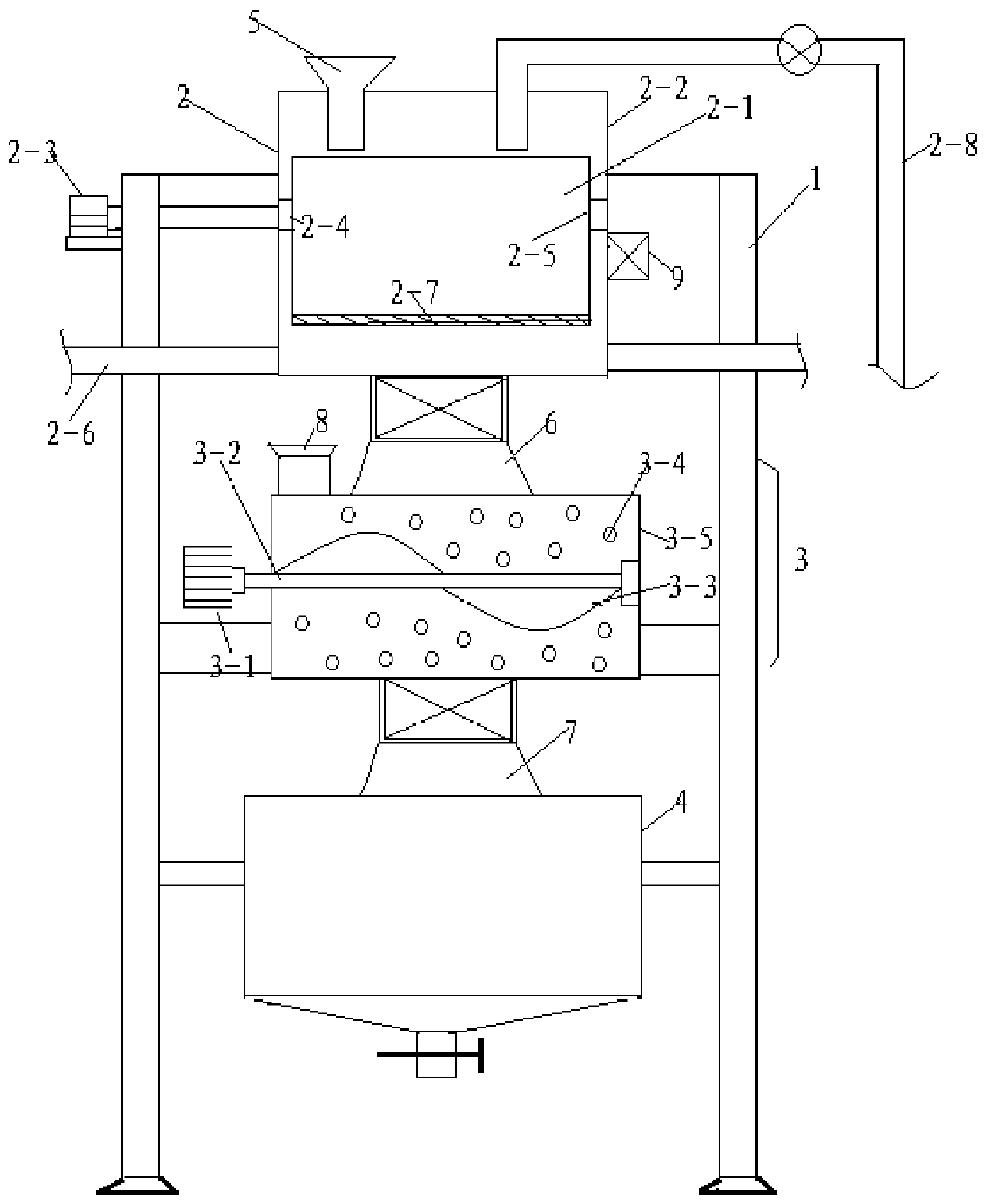

Image

Examples

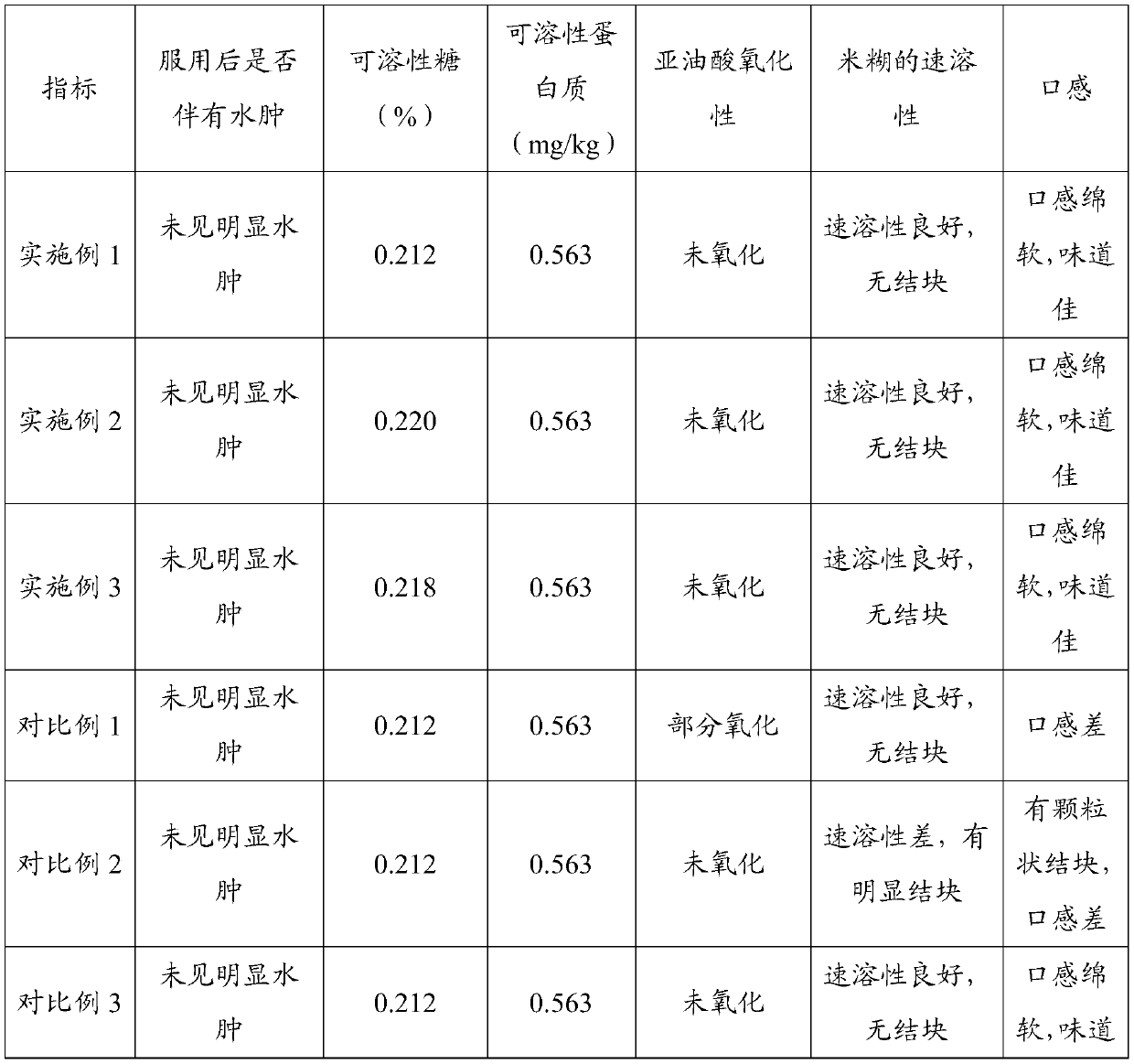

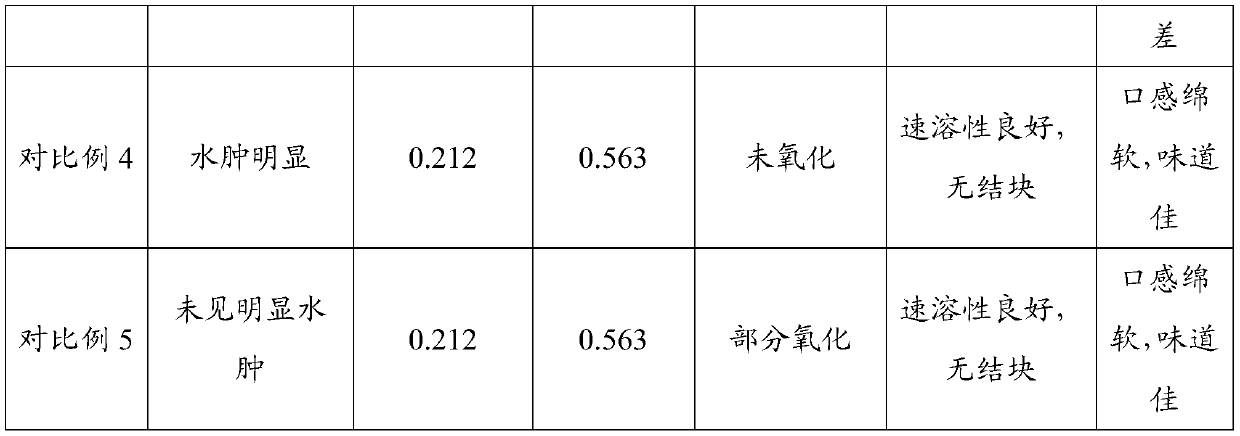

Embodiment 1

[0036] A processing method for multigrain nut nutritional compound paste food, comprising the following steps:

[0037] (1) Material preparation: Weigh 10 parts of high-quality buckwheat, 10 parts of oats, 5 parts of corn, 1 part of japonica rice, 1 part of black soybean, 1 part of peanut, 1 part of sunflower seed and 1 part of almond, and wash with water;

[0038] (2) Ball mill mixing: add water, a mixture of dibutyl hydroxytoluene BHT and butyl hydroxyanisole BHA, sodium diacetate and methyl aspartame to the raw materials cleaned in the above step (1) , stirred and pulverized in a ball mill to prepare miscellaneous grains and nuts powder slurry; wherein 0.005 part of sodium diacetate, 0.1 part of methyl aspartame, 30 parts of water, dibutyl hydroxytoluene BHT and butyl hydroxy anise 0.003 part of ether BHA mixture, and the ratio of dibutyl hydroxytoluene BHT and butyl hydroxyanisole BHA in the mixture is 1:6;

[0039] (3) Spray granulation: use a centrifugal spray granulato...

Embodiment 2

[0041] A processing method for multigrain nut nutritional compound paste food, comprising the following steps:

[0042] (1) Prepare ingredients: choose 12 parts of high-quality buckwheat, 12 parts of oats, 8 parts of corn, 2 parts of japonica rice, 2 parts of black beans, 2 parts of peanuts, 2 parts of sunflower seeds and 2 parts of almonds, wash with water;

[0043] (2) Ball mill mixing: add water, a mixture of dibutyl hydroxytoluene BHT and butyl hydroxyanisole BHA, sodium diacetate and methyl aspartame to the raw materials cleaned in the above step (1) , stirred and pulverized in a ball mill to prepare miscellaneous grains and nuts powder slurry; wherein 0.008 parts of sodium diacetate, 0.15 parts of methyl aspartame, 50 parts of water, dibutyl hydroxytoluene BHT and butyl hydroxy anise 0.004 part of ether BHA mixture, and the ratio of dibutyl hydroxytoluene BHT and butyl hydroxyanisole BHA in the mixture is 1:10;

[0044] (3) Spray granulation: use a centrifugal spray gra...

Embodiment 3

[0046] A processing method for multigrain nut nutritional compound paste food, comprising the following steps:

[0047] (1) Prepare materials: Weigh 15 parts of high-quality buckwheat, 15 parts of oats, 10 parts of corn, 3 parts of japonica rice, 3 parts of black beans, 3 parts of peanuts, 3 parts of sunflower seeds and 3 parts of almonds, and wash them with water;

[0048] (2) Ball mill mixing: add water, a mixture of dibutyl hydroxytoluene BHT and butyl hydroxyanisole BHA, sodium diacetate and methyl aspartame to the raw materials cleaned in the above step (1) , stirred and pulverized in a ball mill to prepare miscellaneous grains and nuts powder slurry; wherein 0.01 part of sodium diacetate, 0.2 part of methyl aspartame, 60 parts of water, dibutyl hydroxytoluene BHT and butyl hydroxy anise 0.005 part of ether BHA mixture, and the ratio of dibutyl hydroxytoluene BHT and butyl hydroxyanisole BHA in the mixture is 1:12;

[0049] (3) Spray granulation: Use a centrifugal spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com