Preparation method of composite material prepared from paper mill sludge and plastic

A technology for papermaking sludge and composite materials, applied in chemical instruments and methods, sludge treatment, plastic recycling, etc., can solve the problems of increasing plastic waste, polluting soil and oceans, low recycling rate, etc. High content, good effect, good performance preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

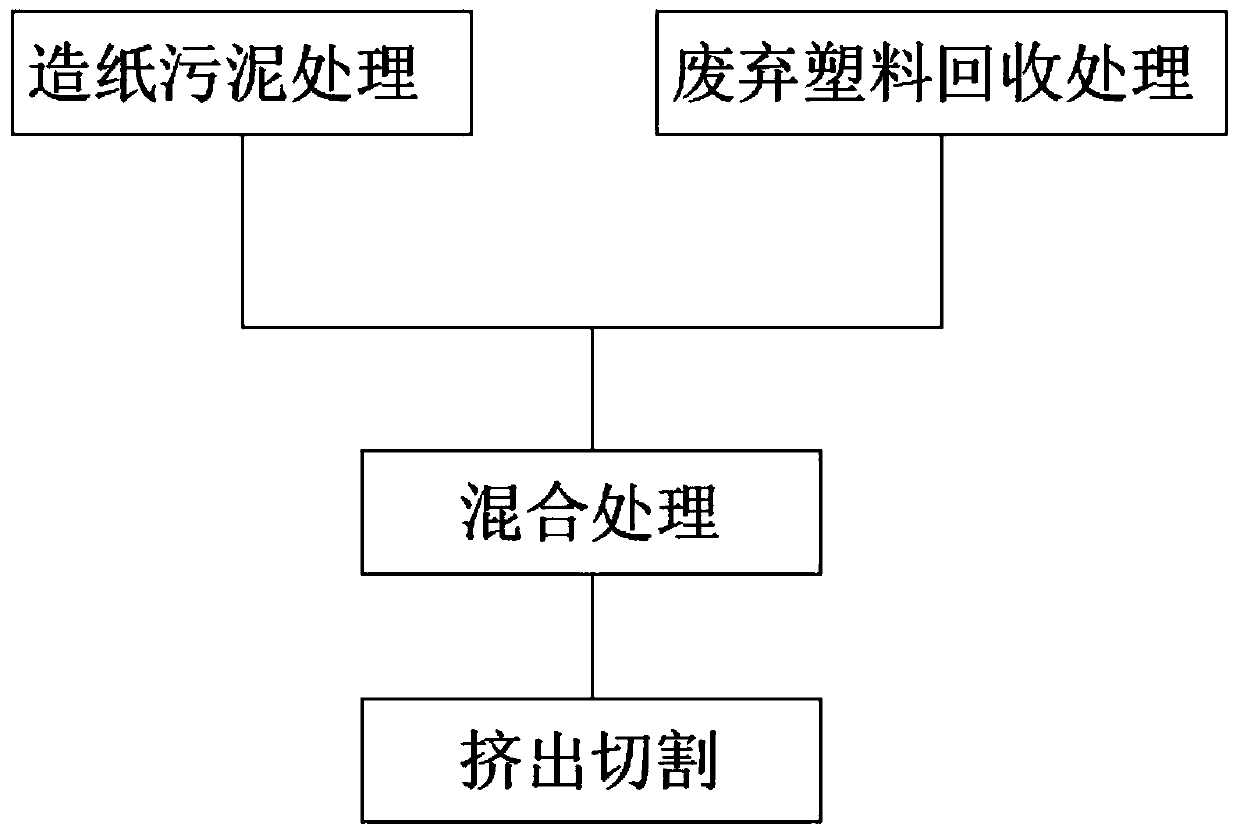

[0023] See also figure 1 , a kind of preparation method of papermaking sludge and plastics manufacturing composite material, comprises the following steps:

[0024] S1: Treat papermaking sludge, pretreatment, drying, crushing and screening, and recycle the fibers in papermaking sludge, which is more convenient and has better treatment effect in the treatment of papermaking sludge,

[0025] The pretreatment is: based on the weight of the papermaking sludge, adding a disinfectant containing 1% by weight, such as hypochlorous acid, to the biochemical papermaking sludge, so that the number of bacteria in the sludge is reduced from 25000 / ml to 1500 / ml Milliliters, papermaking sludge without biochemical treatment may not be pretreated. The biochemically treated papermaking sludge contains a large number of microorganisms, which reproduce and degrade during transportation and accumulation, resulting in stench. Therefore, the present invention uses bactericide and hypochlorous acid t...

Embodiment 2

[0031] See also figure 1 , a kind of preparation method of papermaking sludge and plastics manufacturing composite material, comprises the following steps:

[0032] S1: Treat papermaking sludge, pretreatment, drying, crushing and screening, and recycle the fibers in papermaking sludge, which is more convenient and has better treatment effect in the treatment of papermaking sludge,

[0033] The pretreatment is: based on the weight of the papermaking sludge, adding a disinfectant containing 0.5% by weight in the biochemical papermaking sludge, such as hypochlorous acid, to reduce the number of bacteria in the sludge from 20000 / ml to 1000 / ml Milliliters, papermaking sludge without biochemical treatment may not be pretreated. The biochemically treated papermaking sludge contains a large number of microorganisms, which reproduce and degrade during transportation and accumulation, resulting in stench. Therefore, the present invention uses bactericide and hypochlorous acid to pretre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com