Cuprous oxide/cuprous sulfide/nickel sulfide three-layer photoelectrode and its preparation and application

A technology of cuprous oxide and cuprous sulfide, applied in the field of photoelectrode, can solve the problems of reducing photoelectric conversion efficiency or hydrogen production in the catalytic process, no report of cuprous oxide photoelectrode, reducing catalyst reactivity, etc. High reduction efficiency, improved photocorrosion resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

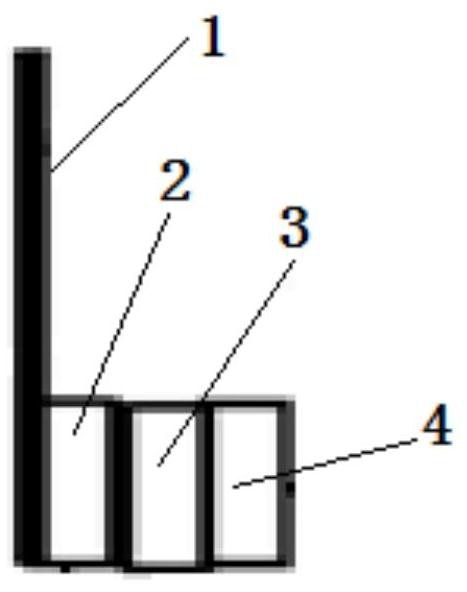

[0032] The preparation method of cuprous oxide / cuprous sulfide / nickel sulfide three-layer photoelectrode of the present invention comprises the following steps:

[0033] 1) Electrodeposition of cuprous oxide (Cu 2 O) film; including:

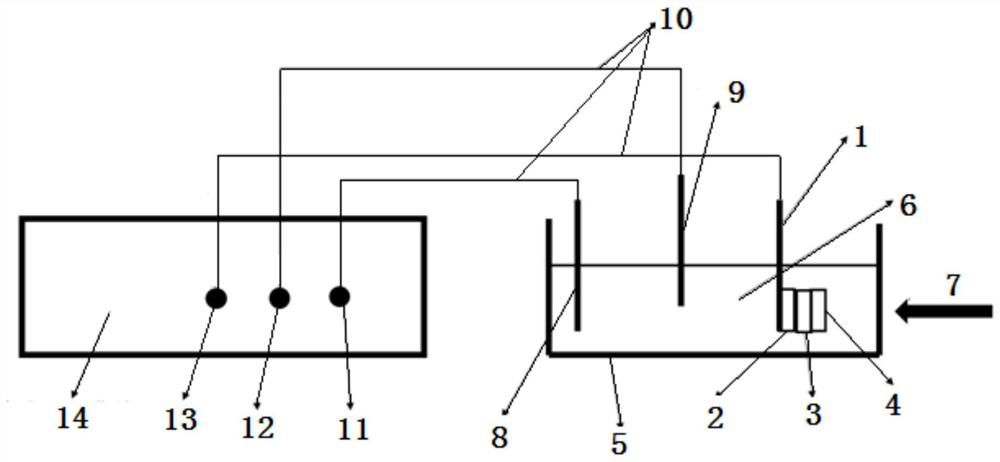

[0034] Sodium hydroxide (NaOH) solution was used to dissolve copper sulfate (Cu 2 SO 4 ) and trisodium citrate to adjust the pH value of the mixed aqueous solution to 10.8 to 11.5, and at a temperature of 60°C to 70°C, use tin dioxide glass (FTO glass) as a carrier, silver / silver chloride (Ag / AgCl) As reference electrode 9, platinum sheet electrode is as counter electrode 8, with the standard electrode potential of silver / silver chloride (Ag / AgCl) reference electrode as standard, under the condition of -0.4V, on the tin dioxide glass carrier Deposit 0.5~2h to prepare cuprous oxide (Cu 2 O) Thin film light.

[0035] 2) Using anion exchange method in cuprous oxide (Cu 2 O) film prepared cuprous sulfide (Cu 2 S) thin film, obtain cuprous oxi...

example 1

[0042] Prepared CuSO 4 (0.05M) and trisodium citrate (0.05M) mixed solution 50mL, then use 1M (1 mole per liter) NaOH solution to adjust the pH value of the mixed solution to 11.0, use an oil bath to adjust the pH value and mix The solution was heated to 65°C, and then tin dioxide glass (FTO) (1cm×2cm) was used as a carrier electrode, silver / silver chloride (Ag / AgCl) was used as a reference electrode, and a platinum sheet electrode was used as a counter electrode. The standard electrode potential of the silver chloride (Ag / AgCl) reference electrode is the standard, and it is deposited on the tin dioxide glass carrier under the condition of -0.4V for 2h, and Cu is prepared on the tin dioxide glass carrier. 2 O film. Then it will be prepared with Cu 2 The tin dioxide glass carrier of the O film is immersed in 1M sodium sulfide solution for 1min and taken out, and blown dry with nitrogen, forms a cuprous sulfide film on the cuprous oxide film, thereby obtains cuprous oxide / cupr...

example 2

[0044] Formulated Cu 2 SO 4 (0.06M) and trisodium citrate (0.06M) mixed solution 50mL, then the pH value of described mixed solution is adjusted to 11.0 with 1M (1 mole per liter) NaOH solution, utilizes oil bath to adjust the pH value after The mixed solution was heated to 65°C, and then tin dioxide glass (FTO) (1cm×2cm) was used as the carrier electrode, silver / silver chloride (Ag / AgCl) was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode. The standard electrode potential of the silver chloride (Ag / AgCl) reference electrode is the standard, and it is deposited on the tin dioxide glass carrier for 0.5h under the voltage of -0.4V, and the Cu is prepared on the tin dioxide glass carrier. 2 O film. Then it will be prepared with Cu 2 The tin dioxide glass carrier of O thin film is immersed in the sodium sulfide solution of 1M 2min, takes out, and blows dry with nitrogen, forms cuprous sulfide thin film on cuprous oxide thin fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com