Photocatalytic material for efficiently removing high-concentration nitrate through photocatalysis as well as preparation method and application of photocatalytic material

A photocatalytic material, photocatalytic technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Evaluation and other issues to achieve the effect of promoting photocatalytic activity, high reduction catalytic activity, and overcoming competition problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for preparing a photocatalytic material for highly efficient photocatalytic removal of high-concentration nitrate, including the following steps:

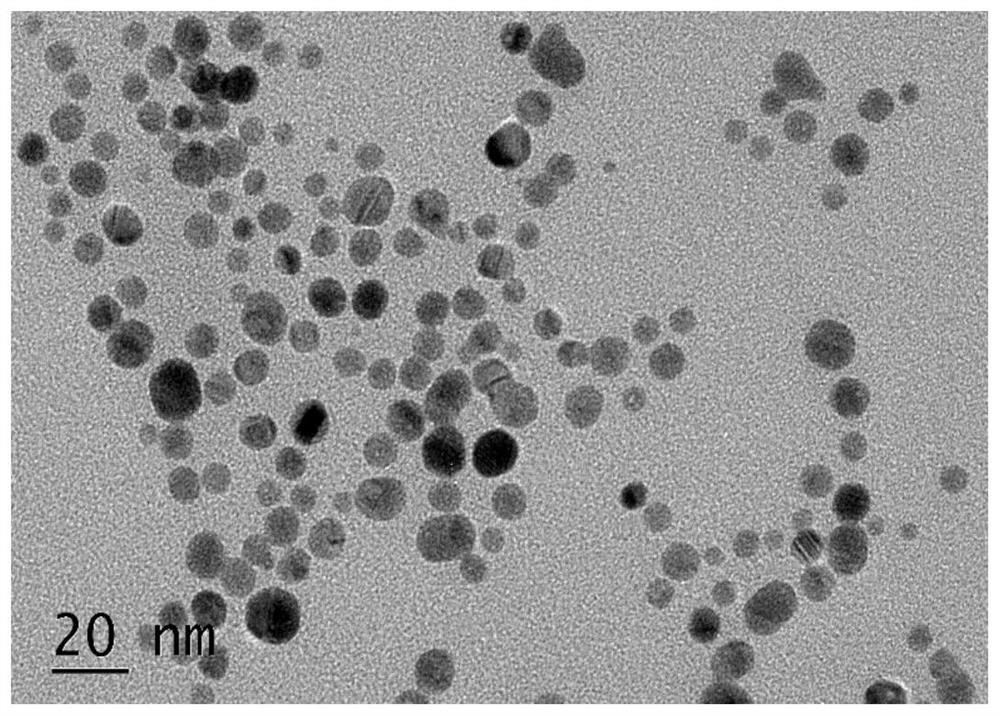

[0045] Step 1, prepare citrate-stabilized silver nanoparticles: 8mL 40mmol L -1 Sodium citrate solution as a stabilizer was added to 100mL 1mmol L -1 in the silver nitrate solution. 2ml 112mmol·L at room temperature -1 NaBH 4 Add the solution dropwise to the above mixture and stir vigorously (1000-1400rpm) to obtain a yellow-brown silver nanoparticle sol solution. Store the obtained silver sol in a refrigerator at 4°C and let it stand for 24 hours to decompose the remaining NaBH 4 , for subsequent use.

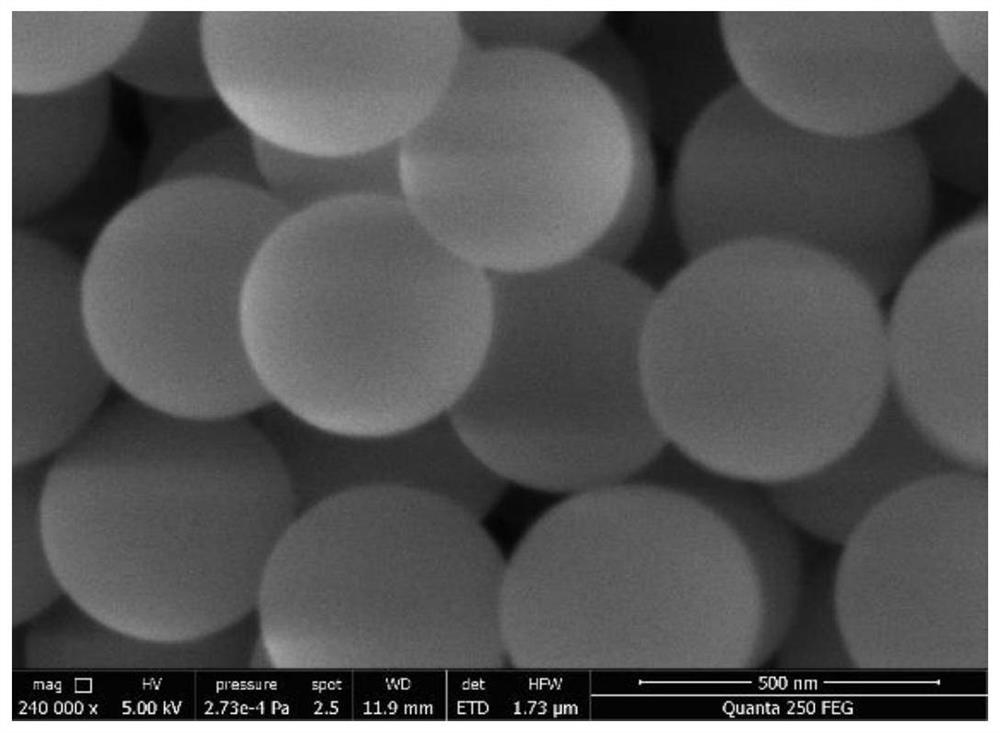

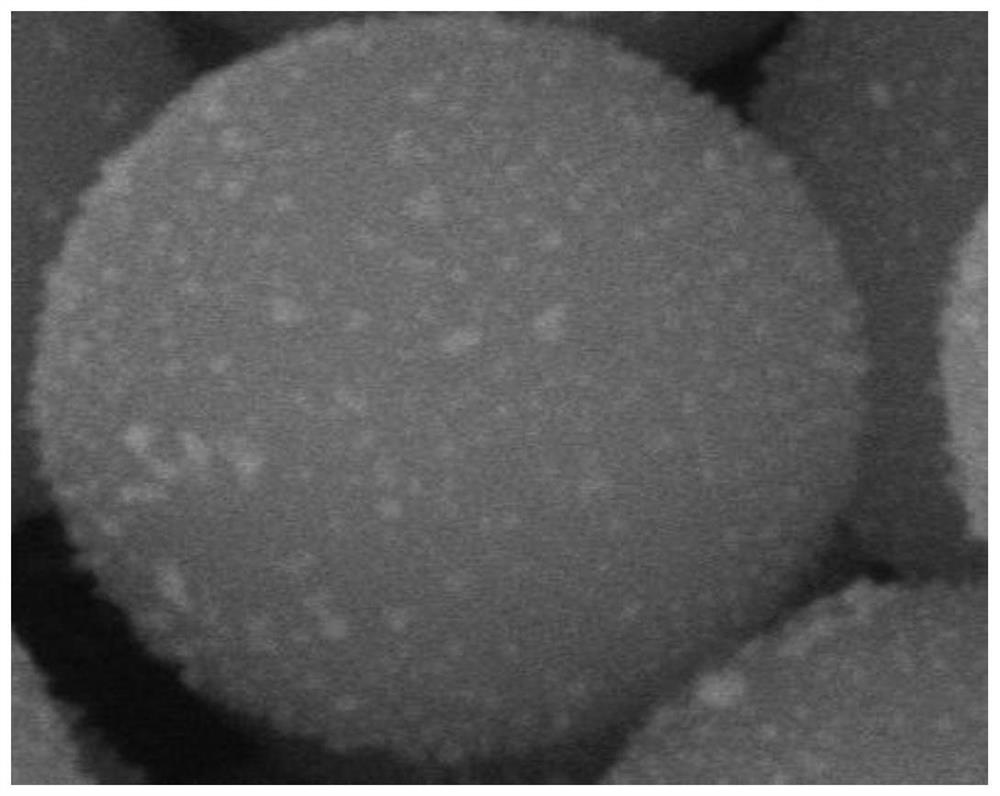

[0046] Step 2. Synthesis and functional modification of SiO 2 : Add 0.6ml of tetraethyl silicate dropwise to a mixed solution of 25mL of water, 15mL of ammonia water and 60mL of isopropanol. The reaction was continued for 30 min with vigorous stirring (1000-1400 rpm) in a 35 °C water ...

Embodiment 2

[0057] This embodiment provides a method for preparing a photocatalytic material for highly efficient photocatalytic removal of high-concentration nitrate, including the following steps:

[0058] Step 1, prepare citrate-stabilized silver nanoparticles: 8mL 40mmol L -1 Sodium citrate solution as a stabilizer was added to 100mL 1mmol L -1 in the silver nitrate solution. 2ml 112mmol·L at room temperature -1 NaBH 4 Add the solution dropwise to the above mixture and stir vigorously (1000-1400rpm) to obtain a yellow-brown silver nanoparticle sol solution. Store the obtained silver sol in a refrigerator at 4°C and let it stand for 24 hours to decompose the remaining NaBH 4 , for subsequent use.

[0059] Step 2. Synthesis and functional modification of SiO 2 : Add 0.6ml of tetraethyl silicate dropwise to a mixed solution of 25mL of water, 15mL of ammonia water and 60mL of isopropanol. The reaction was continued for 30 min with vigorous stirring (1000-1400 rpm) in a 35 °C water ...

Embodiment 3

[0067] This embodiment provides a method for preparing a photocatalytic material for highly efficient photocatalytic removal of high-concentration nitrate, including the following steps:

[0068] Step 1, prepare citrate-stabilized silver nanoparticles: 8mL 40mmol L -1 Sodium citrate solution as a stabilizer was added to 100mL 1mmol L -1 in the silver nitrate solution. 2ml 112mmol·L at room temperature -1 NaBH 4 Add the solution dropwise to the above mixture and stir vigorously (1000-1400rpm) to obtain a yellow-brown silver nanoparticle sol solution. Store the obtained silver sol in a refrigerator at 4°C and let it stand for 24 hours to decompose the remaining NaBH 4 , for subsequent use.

[0069] Step 2. Synthesis and functional modification of SiO 2 : Add 0.6ml of tetraethyl silicate dropwise to a mixed solution of 25mL of water, 15mL of ammonia water and 60mL of isopropanol. The reaction was continued for 30 min with vigorous stirring (1000-1400 rpm) in a 35 °C water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com