Rapid detection method of hydrogen partial pressure for aluminum alloy melt dynamic breathing method hydrogen measurement device

A technology of aluminum alloy melt and detection method, which is applied in the field of casting and metallurgy, can solve the problems of complex structure, high manufacturing and use costs, and inconvenient application of the dynamic breath method hydrogen measurement device, and achieve intelligent, intuitive and easy-to-operate detection , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

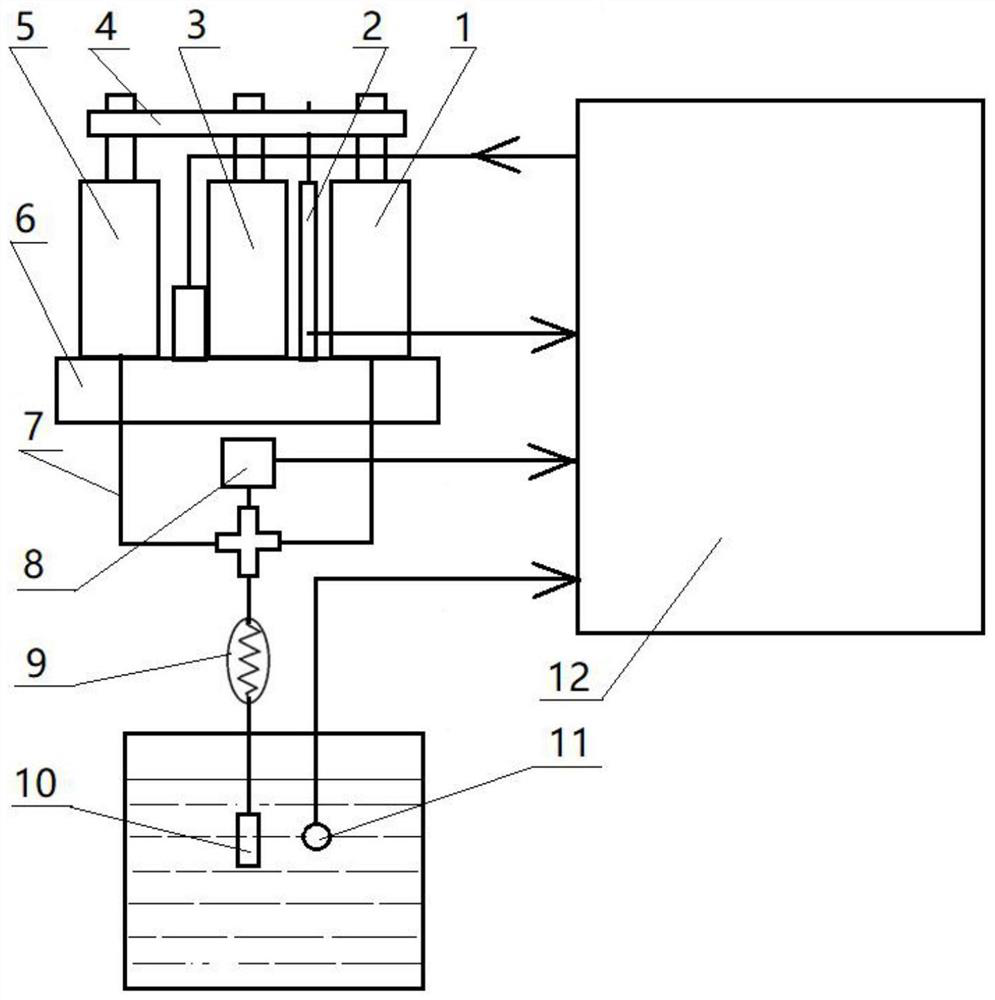

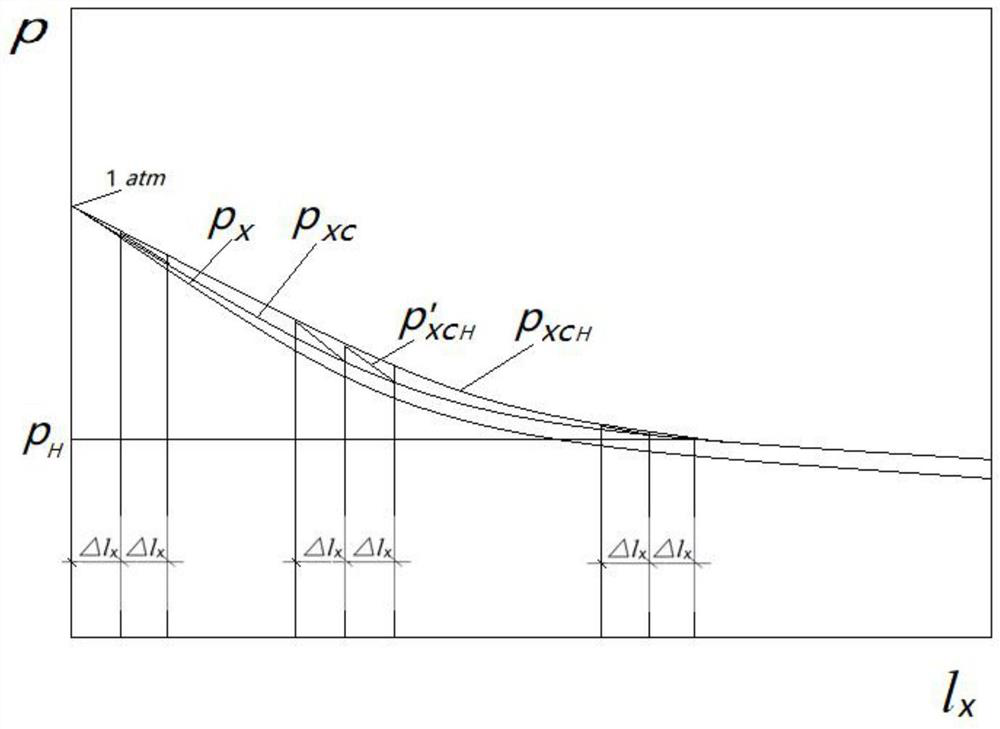

[0023] Embodiment 1: Combining figure 1 , figure 2 Illustrating this embodiment, a method for rapidly detecting hydrogen partial pressure for an aluminum alloy melt dynamic respiration method for hydrogen measurement device of this embodiment includes the following steps:

[0024]Step 1: Build a rapid hydrogen partial pressure detection system for aluminum alloy melt dynamic breathing method hydrogen measurement device. The first cylinder 1, the displacement sensor 2, the electric push rod 3 and the second cylinder 5 are fixed on the fixed base plate 6. The first cylinder A rigid beam 4 is fixedly connected to the upper part of the output end of 1, the telescopic end of the displacement sensor 2, the output end of the electric push rod 3 and the output end of the second cylinder 5. The first cylinder 1 and the second cylinder 5 are located at the electric push rod 3 and the upper part of the output end of the second cylinder 5. On both sides of the displacement sensor 2, the...

specific Embodiment approach 2

[0037] Specific implementation mode 2: Combining figure 1 Illustrating this embodiment, a kind of aluminum alloy melt dynamic breathing method hydrogen measurement device of this embodiment uses a hydrogen partial pressure rapid detection method, and the computer measurement and control unit 12 includes a computer, an analog signal amplifier, a relay, and an input / output interface circuit, It is convenient for data processing and intuitive display.

specific Embodiment approach 3

[0038] Specific implementation three: combination figure 1 Illustrating this embodiment, a method for rapid detection of hydrogen partial pressure for an aluminum alloy melt dynamic breathing method hydrogen measurement device of this embodiment, the fixed bottom plate 6 and the rigid beam 4 are high-strength and high-rigidity materials, and the displacement sensor is improved. 2 The accuracy of the measurement data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com