A kind of soft and hard carbon composite porous negative electrode material for sodium ion battery and preparation method thereof

A technology for sodium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle stability and reversibility of rate performance, and achieve improved rate performance, simple preparation methods, and accelerated electrons. The effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of a soft and hard carbon composite porous negative electrode material for sodium ion batteries

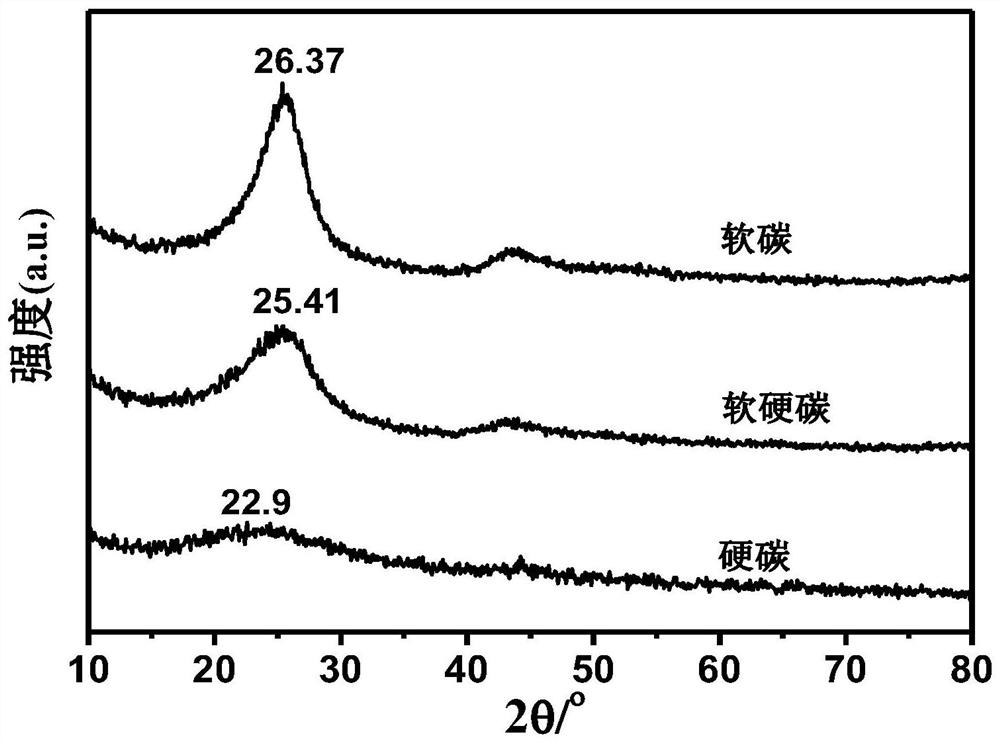

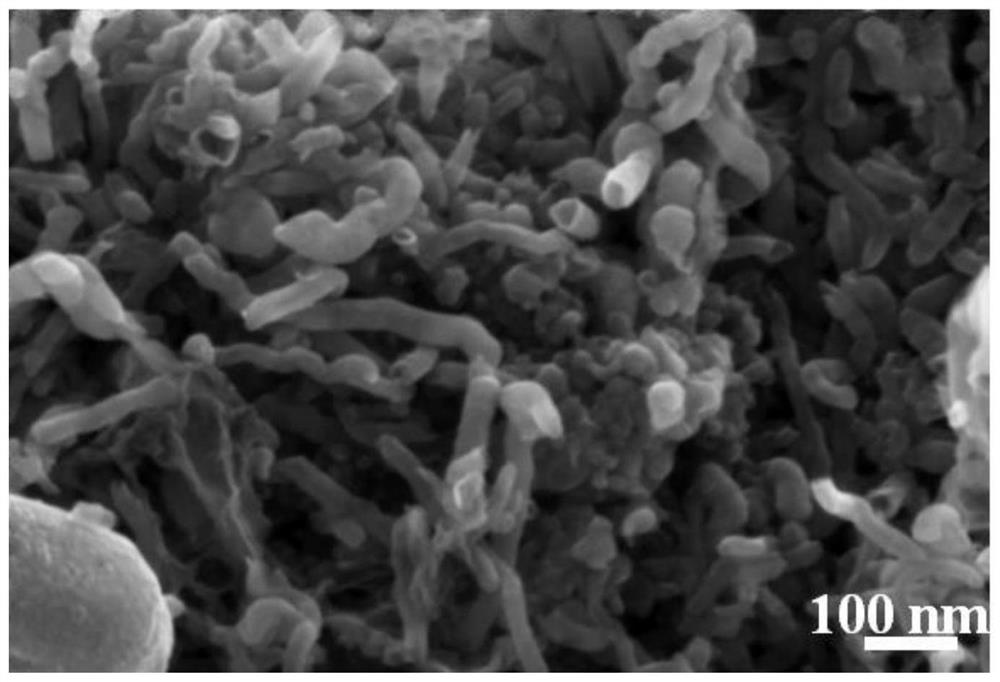

[0032] 60 mL of ethanolic solution of dimethylimidazole (containing 930 mg of dimethylimidazole) was added dropwise to 60 mL of ethanolic solution of cobalt nitrate (containing 100 mg of cobalt nitrate), and after rapid stirring at room temperature for 30 min, the precursor (ZIF) was obtained. -67) solution. 5g of polyvinyl alcohol was added to the precursor solution, refluxed at 85°C for 2h to form a gel, cooled naturally, freeze-dried at -60°C for 12h, and then placed in an inert gas atmosphere at 1000°C for 4h heat treatment to obtain a sodium-ion battery. Soft and hard carbon composite porous anode material. Depend on figure 1 It can be seen that the X-ray diffraction (XRD) pattern of the soft and hard carbon composite porous negative electrode material prepared in Example 1 shows that the peak shape of the composite material is between the pure soft and h...

Embodiment 2

[0040] Preparation of a soft carbon anode material for sodium ion batteries

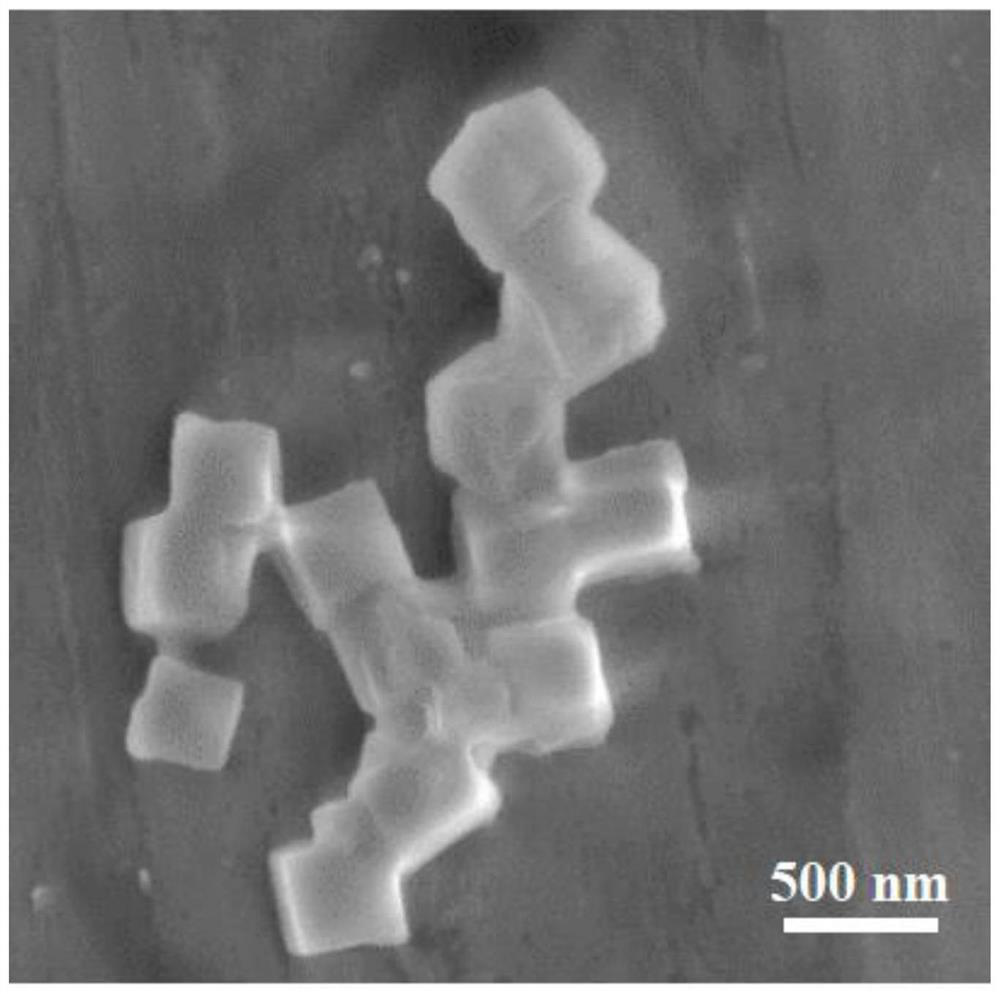

[0041] 60 mL of an ethanolic solution of dimethylimidazole (containing 930 mg of dimethylimidazole) was added dropwise to 60 mL of an ethanolic solution of cobalt nitrate (containing 100 mg of cobalt nitrate). The mixed solution was left standing for 24 hours, centrifuged, washed and dried to obtain the precursor ZIF-67. Then the precursor ZIF-67 was placed in a magnetic boat, heated to 600°C at a heating rate of 5°C / min, kept in a nitrogen atmosphere for 4 hours, and then soaked in 35% hydrochloric acid for 3 hours after natural cooling to remove The residual Co element on the sample is finally washed with deionized water, suction filtered, and dried to obtain a soft carbon negative electrode material.

[0042] Depend on figure 1 It can be seen that the X-ray diffraction (XRD) pattern of the soft carbon negative electrode material prepared in Example 2 shows two diffraction peaks (002) and (101). ...

Embodiment 3

[0045] Preparation of a hard carbon anode material for sodium ion batteries

[0046] Dissolve 5 g of polyvinyl alcohol in 10 mL of deionized water, stir it ultrasonically for 30 min to make it evenly dispersed, and then transfer it to a single-neck round-bottomed flask, reflux and stir at 85 °C for 5 h to form a gel, cool, centrifuge, and freeze-dry at -60 °C for 12 h to obtain The precursor was placed in a magnetic boat, heated to 1000°C at a heating rate of 2°C / min, kept for 4h in a nitrogen atmosphere, and naturally cooled to obtain a hard carbon anode material for sodium ion batteries.

[0047] Depend on figure 1 It can be seen that the X-ray diffraction (XRD) pattern of the hard carbon anode material prepared in Example 3 shows that the hard carbon exhibits two broad diffraction peaks, indicating an amorphous structure, and the 2θ is the crystal corresponding to the peak at 22.9°. The lattice spacing of 0.4 nm, which is larger than that of soft carbon (>0.35 nm), favors ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com