Multifunctional composite negative plate for rechargeable solid battery, preparation method and secondary battery

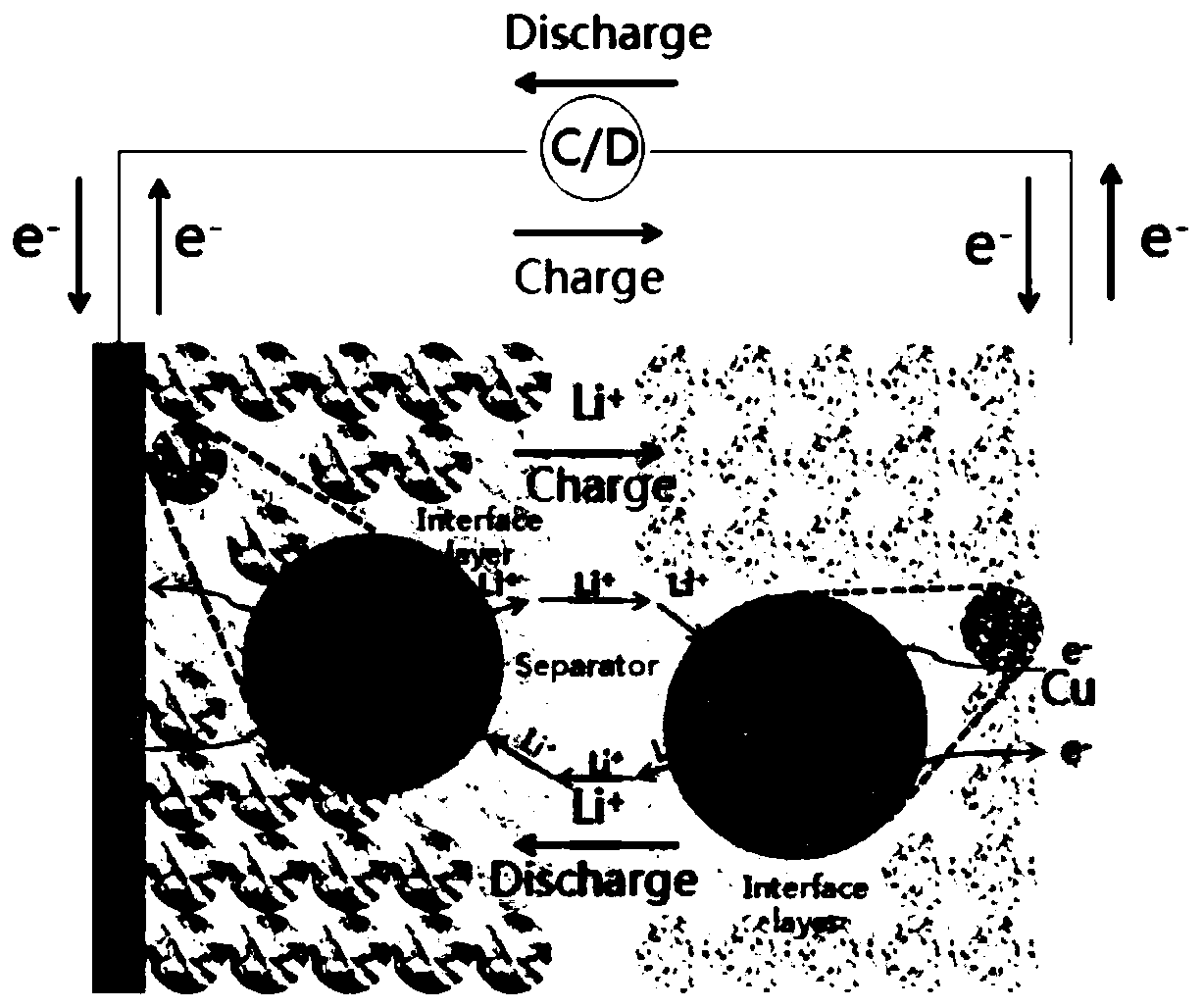

A solid battery, multi-functional technology, applied in the direction of secondary batteries, battery electrodes, electrode carriers/collectors, etc., can solve the problem that the negative plate cannot be directly applied to solid-state batteries, organic liquid electrolytes are flammable, and cannot realize ion transport functions, etc. problems, to achieve excellent rate characteristics, enhanced functions, and enhanced adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0089] The invention provides a method for preparing a multifunctional composite negative electrode sheet, the method comprising: sequentially forming a negative electrode active material layer and a negative electrode ion conducting electronic insulating layer on a negative electrode current collector layer,

[0090] Preferably, the negative electrode active material layer and the negative electrode ion conductive electronic insulating layer are sprayed, equidistant extrusion coating, sputtering with a mask structure, roll pressing, chemical vapor deposition, atomic layer deposition, electrochemical deposition, 3D Prepared on the negative electrode current collector layer by printing or the like,

[0091] More preferably, the negative electrode active material layer is first prepared on the negative electrode current collector layer, and then the ion-conducting electronic insulating layer is prepared on the negative electrode active material layer, and the preparation method o...

Embodiment 1

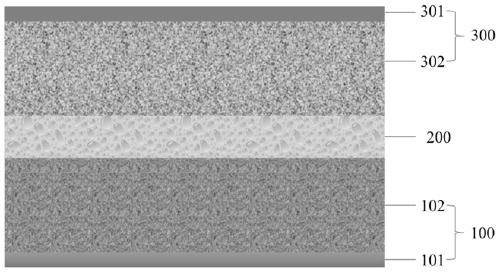

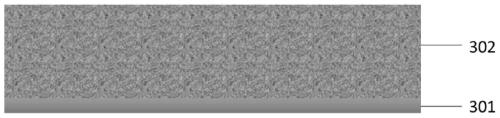

[0102] Such as Figure 4 As shown, a multifunctional composite negative electrode sheet for rechargeable solid batteries includes a negative electrode current collector layer 301 distributed in a two-dimensional stacked structure, a negative electrode active material layer 302 and a negative electrode ion conduction electronic insulating layer 303, wherein the negative electrode current collector The base material of layer 301 is copper foil, the negative electrode material of the negative electrode active material layer 302 is graphite, the mass fraction is 80%, the binder is polyvinylidene fluoride, the mass fraction is 9%, and the electronic conductive additive is carbon black, the mass fraction is 3%, the ionic conductive additives are lithium bistrifluoromethanesulfonylimide and lithium titanium aluminum phosphate, each with a mass fraction of 4%, and the negative electrode ion conductive electronic insulating layer 303 is lithium lithium titanium phosphate and polyvinylid...

Embodiment 2

[0108] Such as Figure 5 As shown, a multifunctional composite negative electrode sheet for rechargeable solid batteries includes a negative electrode current collector layer 301 distributed in a two-dimensional stacked structure, a negative electrode active material layer 302 and a negative electrode ion conduction electronic insulating layer 303, wherein the negative electrode current collector The base material of layer 301 is copper foil, and the negative electrode active material layer includes two negative electrode active material components, which are respectively the first negative electrode active material component 3021 and the second negative electrode active material component 3022,

[0109] The negative electrode material of the first negative electrode active material assembly 3021 is hard carbon, with a mass fraction of 90%, the binder is polyvinylidene fluoride, with a mass fraction of 4%, and the electronically conductive additive is carbon black, with a mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com