A kind of non-aqueous electrolyte and lithium ion battery

A non-aqueous electrolyte and lithium salt technology, applied in the field of materials, can solve the problems of high flammability and potential safety hazards of lithium-ion battery technology, and achieve the effects of reducing swelling, excellent thermal stability, and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application is described in detail below in conjunction with the examples, but the present application is not limited to these examples. Unless otherwise specified herein, "%" represents mass percentage, and ratio represents mass ratio.

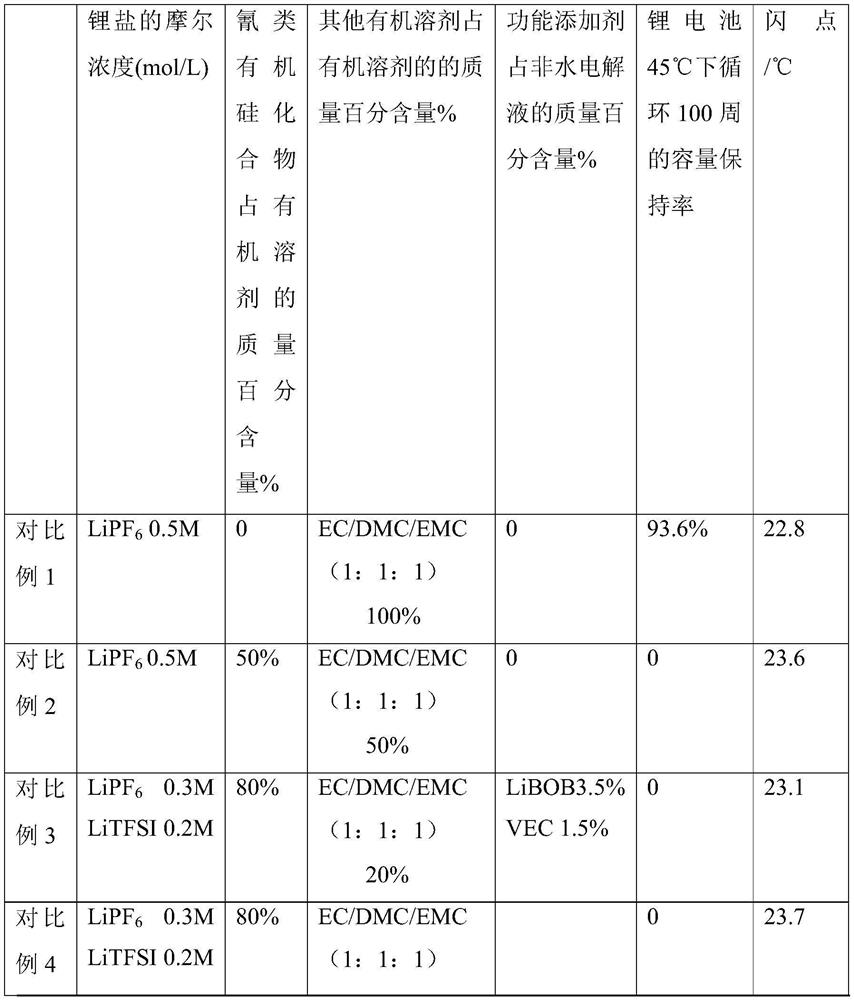

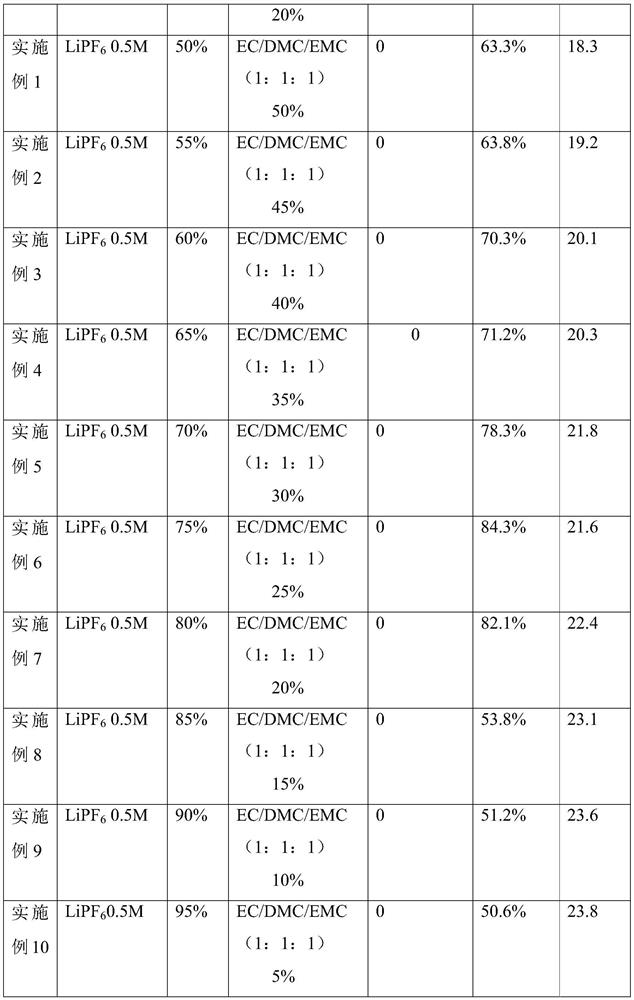

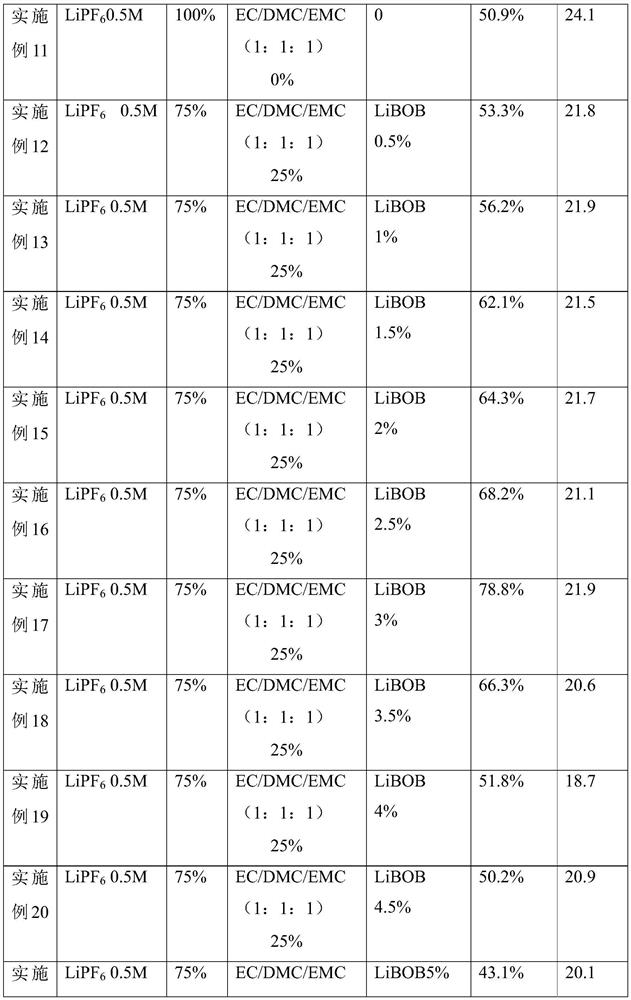

[0022] Table 1 lists the composition of the non-aqueous electrolytes of the examples and the comparative examples, and the capacity retention rate and the flash point of the electrolytes of the batteries using the non-aqueous electrolytes of the examples and the comparative examples. Battery capacity retention test method: add the electrolyte dropwise to the lithium cobalt oxide button, assemble it into a button half battery, charge and discharge at room temperature 0.2C, divide the discharge capacity of 100 cycles by the first cycle The discharge capacity is the capacity retention rate. The flash point of the electrolyte adopts the closed cup method to measure the flash point of the electrolyte prepared by the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com