Extraction method for tripterygium glycosides

A technology of triptolide polyglycoside and extraction method, which is applied in the field of natural medicine extraction, can solve the problems of environmental pollution, low purity of triptolide, large amount of solvent, etc., and achieve easy operation, improved extraction rate and purity, and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation method

[0031] (1) The roots of Tripterygium wilfordii are selected and processed into small pieces, and crushed to 60 mesh by a pulverizer to obtain a powder sample.

[0032] (2) Weigh 15 g of the powder sample, add the powder sample to 60% ethanol, the ratio of solid to liquid is 1:20, conduct ultrasonic extraction at 250W, 65°C for 80min, and concentrate the extract to 20% of the volume.

[0033] (3) Add the concentrate obtained in step (2) into chloroform, the ratio of solid to liquid is 1:1.5, microwave extraction at 350W, 61°C for 100min, concentrate the extract to a specific gravity of 1.4, and drain the concentrate to obtain Tripterygium wilfordii Polyglycoside powder.

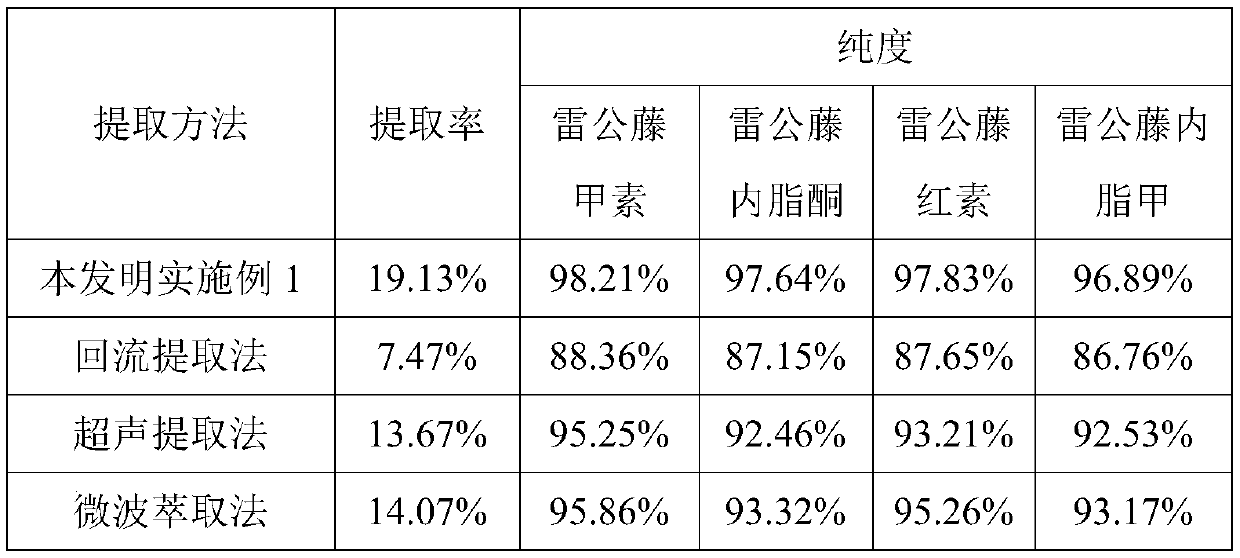

[0034] 2. Tested

[0035] The yield of tripterygium polyglycosides is 2.87g, and the extraction rate is 19.13%, wherein the purity of triptolide is 98.21%, the purity of triptolide ketone is 97.64%, the purity of triptolide is 97.83%, and the purity of triptolide A The purity ...

Embodiment 2

[0037] (1) The roots of Tripterygium wilfordii are selected and processed into small pieces, and crushed to 80 mesh by a pulverizer to obtain a powder sample.

[0038] (2) Weigh 15 g of the powder sample, add the powder sample to 55% ethanol with a solid-to-liquid ratio of 1:25, conduct ultrasonic extraction at 300W and 75°C for 70 min, and concentrate the extract to 25% of its volume.

[0039] (3) Add the concentrate obtained in step (2) into chloroform, the ratio of solid to liquid is 1:2, microwave extraction at 380W, 62°C for 90 minutes, concentrate the extract to a specific gravity of 1.6, and drain the concentrate to obtain Tripterygium wilfordii Polyglycoside powder.

[0040] 2. Tested

[0041] The yield of tripterygium polyglycosides is 2.72g, and the extraction rate is 18.13%, wherein the purity of triptolide is 98.10%, the purity of triptolide ketone is 97.73%, the purity of triptolide is 97.41%, and the purity of triptolide A The purity is 97.24%.

Embodiment 3

[0043] (1) The root of Tripterygium wilfordii is selected and processed into small pieces, and crushed to 50 mesh by a pulverizer to obtain a powder sample.

[0044] (2) Weigh 15 g of the powder sample, add the powder sample to 50% ethanol, the ratio of solid to liquid is 1:15, ultrasonically extract for 100 min at 200W and 60°C, and concentrate the extract to 15% of the volume.

[0045] (3) Add the concentrate obtained in step (2) into chloroform, the ratio of solid to liquid is 1:1, microwave extraction at 280W, 60°C for 120min, concentrate the extract to a specific gravity of 1.2, and drain the concentrate to obtain Tripterygium wilfordii Polyglycoside powder.

[0046] 2. Tested

[0047] The yield of tripterygium polyglycosides is 2.69g, and the extraction rate is 17.93%, wherein the purity of triptolide is 97.61%, the purity of triptolide ketone is 97.13%, the purity of triptolide is 96.56%, and the purity of triptolide A The purity is 96.71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com