Preparation method of sleeping dispersible tablets

A technology of dispersible tablets and extractors, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problem of inability to remove hydrophilic ingredients, affect the next tableting process Particles are easy to absorb moisture and other problems, to achieve the effect of shortening the disintegration time limit, improving bioavailability, and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

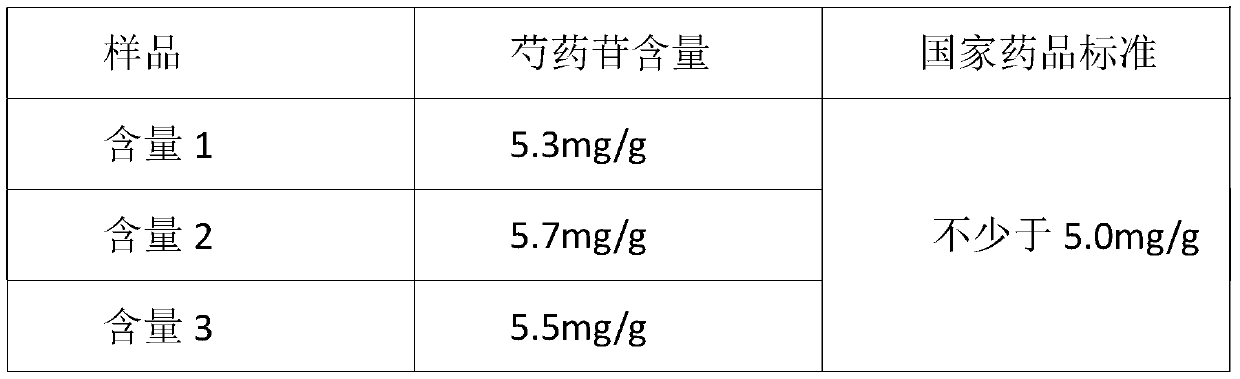

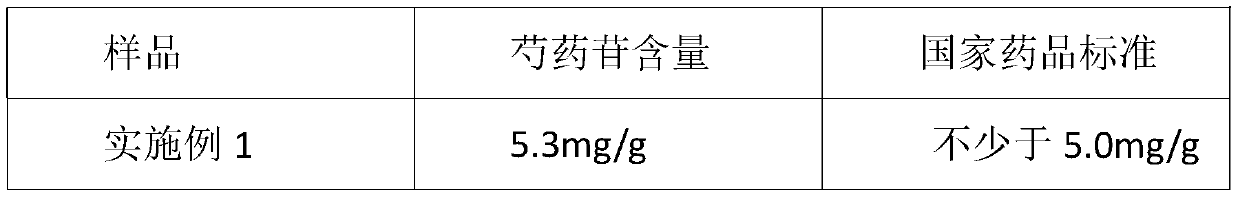

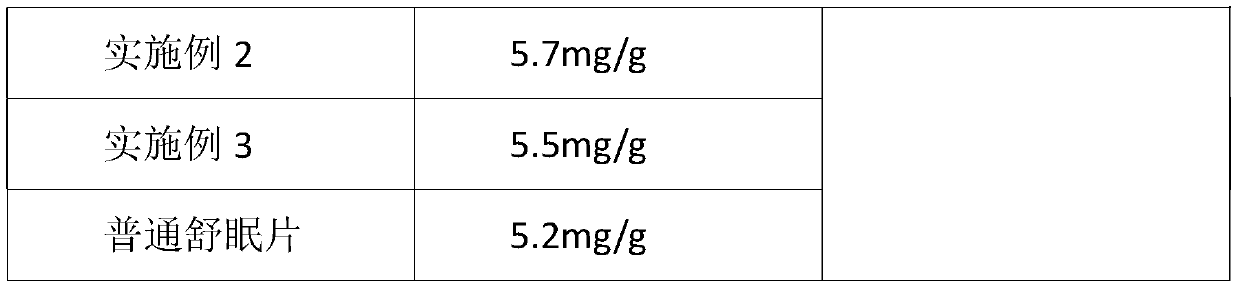

Examples

Embodiment 1

[0041] A preparation method of Shumian Dispersible Tablets, comprising the following steps:

[0042] (1) Take 600g jujube seed, 350g Bupleuri, 350g white peony, 450g Albizia julibrissin, 450g Albizia juniper skin, and 250g silkworm, and put them in the extractor, add 10 times the amount of water, heat and boil the medicinal materials, keep boiling for 1 hour, and fry Boil twice, combine the decoction liquid, and add ethanol after the liquid is allowed to cool to room temperature, so that the alcohol content is 75%, stir while adding, move to the cold storage after the addition is completed, and stand at 5-10°C for 24 hours, filter the supernatant with suction.

[0043] (2) Take 25 g of the medicinal material rushes and place it in an extractor, add 8 times the amount of ethanol, reflux extraction twice, and combine the extracts.

[0044](3) The above supernatant and extract were combined, concentrated under reduced pressure to a clear paste with a relative density of 1.05 (70...

Embodiment 2

[0049] A preparation method of Shumian Dispersible Tablets, comprising the following steps:

[0050] (1) Take 650g jujube seed, 380g bupleurum, 380g white peony root, 480g albizia julibrissin, 480g albizia juniper skin, and 300g silkworm, and put them in an extractor, add 10 times the amount of water, heat and boil the medicinal materials, keep boiling for 1 hour, and fry Boil twice, combine the decoction liquid, and add ethanol after the liquid is allowed to cool to room temperature, so that the alcohol content is 75%, stir while adding, move to the cold storage after the addition is completed, and stand at 5-10°C for 24 hours, filter the supernatant with suction.

[0051] (2) Take 30 g of rushes, a medicinal material, and place it in an extractor, add 8 times the amount of ethanol, perform reflux extraction twice, and combine the extracts.

[0052] (3) The above supernatant and extract were combined, concentrated under reduced pressure to a clear paste with a relative densi...

Embodiment 3

[0057] A preparation method of Shumian Dispersible Tablets, comprising the following steps:

[0058] (1) Take 700g jujube seed, 400g bupleurum, 400g white peony root, 500g albizia julibrissin, 500g albizia juniper skin, and 350g silkworm, and put them in the extractor, add 10 times the amount of water, heat and boil the medicinal materials, keep boiling for 1 hour, and fry Boil twice, combine the decoction liquid, and add ethanol after the liquid is allowed to cool to room temperature, so that the alcohol content is 75%, stir while adding, move to the cold storage after the addition is completed, and stand at 5-10°C for 24 hours, filter the supernatant with suction.

[0059] (2) Take 35 g of the medicinal material rushes and place it in an extractor, add 8 times the amount of ethanol, reflux extraction twice, and combine the extracts.

[0060] (3) The above supernatant and extract were combined, concentrated under reduced pressure to a clear paste with a relative density of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com