High-temperature magnesium oxide calcining device and calcining method thereof

A magnesium oxide device and high-temperature calcination technology, which is applied in the field of magnesia calcination, can solve the problems of equipment production methods without molding industrial cases, etc., and achieve the effects of improving the effective utilization rate of heat, uniform calcination treatment, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

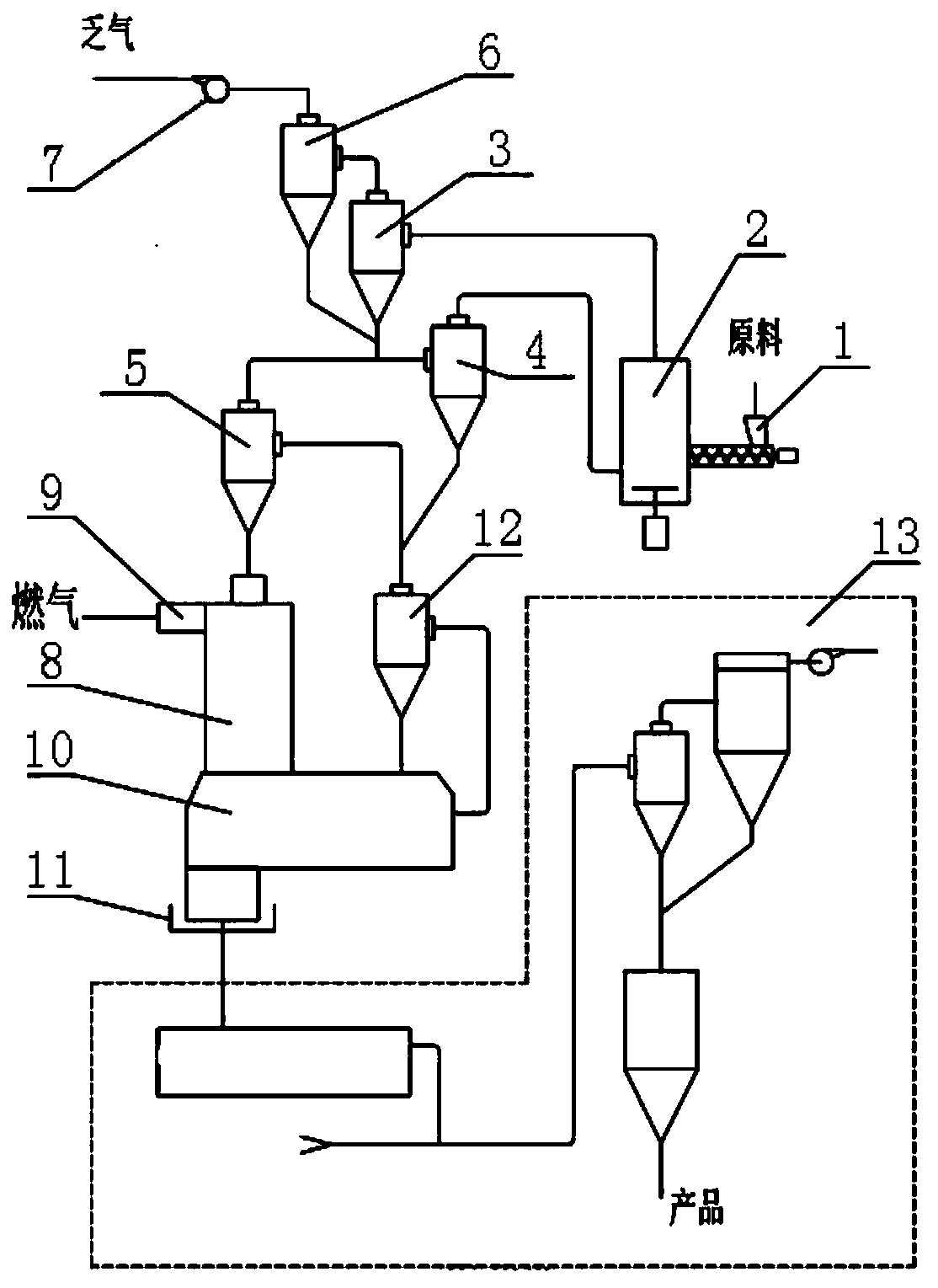

[0039] A high-temperature calcined magnesia device, comprising a feeder 1, an airflow dryer 2, a first-stage cyclone preheater 3, a second-stage cyclone preheater 4, a third-stage cyclone preheater 5, a dust collector 6, Induced fan 7, calciner 8, automatic gas burner 9, heat preservation and tempering furnace 10, discharge device 11, material collector 12 and cooling system 13, such as figure 1 shown;

[0040]The feeder 1 is connected with the sidewall feed inlet of the airflow dryer 2; the upper air outlet on the top of the airflow dryer 2 is connected to the sidewall inlet of the first stage cyclone preheater 3 through a pipeline; the airflow The lower air outlet of the side wall of the dryer 2 is connected to the top air outlet of the second-stage cyclone preheater 4 through a pipeline; the top air outlet of the first-stage cyclone preheater 3 is connected to the side wall air inlet of the dust collector 6 through a pipeline; The top air outlet of the dust collector 6 is ...

Embodiment 2

[0066] A high-temperature calcined magnesia device, comprising a feeder 1, an airflow dryer 2, a first-stage cyclone preheater 3, a second-stage cyclone preheater 4, a third-stage cyclone preheater 5, a dust collector 6, Induced fan 7, calciner 8, automatic gas burner 9, heat preservation and tempering furnace 10, discharge device 11, material collector 12 and cooling system 13, such as figure 1 shown;

[0067] The feeder 1 is connected with the sidewall feed inlet of the airflow dryer 2; the upper air outlet on the top of the airflow dryer 2 is connected to the sidewall inlet of the first stage cyclone preheater 3 through a pipeline; the airflow The lower air outlet of the side wall of the dryer 2 is connected to the top air outlet of the second-stage cyclone preheater 4 through a pipeline; the top air outlet of the first-stage cyclone preheater 3 is connected to the side wall air inlet of the dust collector 6 through a pipeline; The top air outlet of the dust collector 6 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com