Preparation method of crude oil demulsifier applicable to ASP flooding

A crude oil demulsifier and ternary composite technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of crude oil extraction, transportation, processing, storage obstacles, oil-water separation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

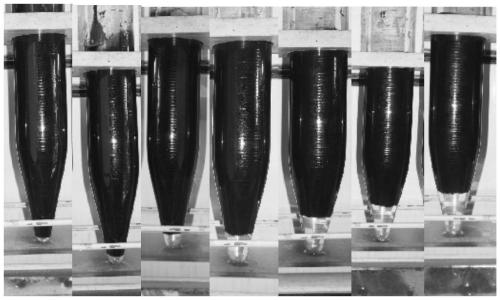

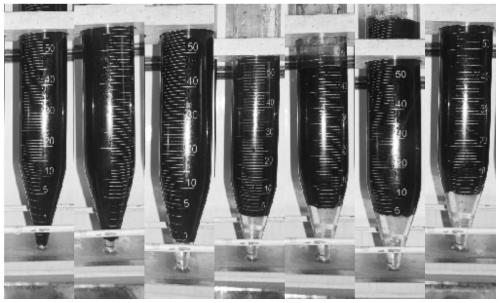

Image

Examples

preparation example Construction

[0017] The present invention relates to a kind of preparation method that is suitable for the crude oil demulsifier of ASP flooding, and the structural general formula of described demulsifier is as follows:

[0018]

[0019] in:

[0020] Described preparation method comprises the steps:

[0021] In the first step, put quantitative perfluorobutyramide and catalyst potassium hydroxide into the high-pressure reaction kettle to seal, the amount of potassium hydroxide is 0.2% to 0.4% of the total mass of perfluorobutanamide, and use nitrogen purging to replace the air in the kettle , use a vacuum pump to evacuate to gauge pressure -0.086MPa, heat the high-pressure reactor to 140°C, open the feed valve, slowly add ethylene oxide, and feed the mass ratio of ethylene oxide to perfluorobutanamide The range is between 1.7:1 and 5.0:1, and the pressure of the reactor is controlled between 0.19MPa and 0.21MPa. After the addition of ethylene oxide is completed, the feed valve is clo...

Embodiment approach

[0024] In the first step, the catalyst for the reaction is potassium hydroxide, and the amount of potassium hydroxide is 0.3% of the mass of perfluorobutyramide;

[0025] In the first step, the mass ratio of ethylene oxide to perfluorobutyramide ranges from 1.7:1 to 5.0:1.

[0026] In the first step, the reaction temperature in the high-pressure reactor is 140°C, and the pressure gauge reading of the reactor is between 0.2±0.01Mpa during the reaction;

[0027] In the second step, the temperature of the first oil bath is 70°C, and stirring is required for 15-25 minutes after adding potassium hydroxide; the temperature of the second oil bath is 90°C, and the modifier is added dropwise; the temperature of the third oil bath is 110℃, the holding time is 8h;

[0028] In the second step, the catalyst of the reaction is potassium hydroxide, and the potassium hydroxide consumption is 0.12% of the intermediate product A quality of quantitative M;

[0029] In the second step, the modi...

Embodiment 1

[0034] In the first step, put 100g of perfluorobutyramide and 0.3g of potassium hydroxide into the autoclave to seal it, use nitrogen purge to replace the air in the autoclave, and use a vacuum pump to evacuate the autoclave to a gauge pressure of -0.086MPa , heat the high-pressure reactor to 140°C, open the feed valve, slowly add 170g of ethylene oxide, control the pressure of the reactor between 0.19MPa and 0.21MPa, and close the inlet valve after the addition of ethylene oxide is completed. Feed valve; after the reactants are fully reacted, the reaction ends when the reaction kettle drops to gauge pressure -0.086MPa, and the intermediate product A is obtained;

[0035] In the second step, take 180g of the intermediate product A obtained through the first step and add it to a three-part bottle, continue to stir and use an oil bath to raise the temperature to 70°C, add 0.2g of potassium hydroxide to the three-part bottle, and continue the oil bath Raise the temperature to 90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com