Polycarbonate composite material and preparation method thereof

A technology of polycarbonate and composite materials, applied in the field of polycarbonate composite materials and its preparation, can solve problems such as silver cracks, easy failure of materials, uneven composition distribution, etc., to prevent crack initiation, efficient and convenient preparation process, Remarkable effect of toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

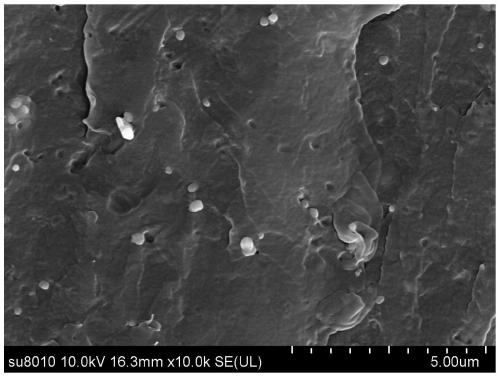

Embodiment 1

[0038] The polycarbonate composite material of the present embodiment includes: by weight, 100 parts of bisphenol A type polycarbonate, 20 parts of talcum powder, 20 parts of MBS, 5 parts of silane coupling agent, 2 parts of fatty acid soap, phthalocyanines 1 part of pigment masterbatch, wherein the particle size of talcum powder is 1 micron.

[0039] The preparation method of the polycarbonate composite material of the present embodiment, comprises the following steps:

[0040] (1) Drying the above-mentioned components at 50° C. for 5 hours to obtain a component with a moisture content lower than 0.02% after drying;

[0041] (2) Stir the dried inorganic particles, compatibilizer and lubricant at 100°C in an anchor stirrer at 100r / min for 2min, then at 300r / min for 3min and mix well;

[0042] (3) Stir the mixture of step (2) and the dried organic toughening agent at a temperature of 100° C. in a hinged stirrer at 200 r / min for 5 min and mix evenly;

[0043] (4) Stir the drie...

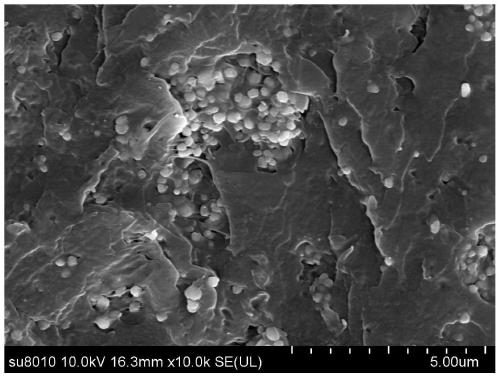

Embodiment 2

[0046] The polycarbonate composite material of this embodiment includes: by weight, 80 parts of bisphenol A type polycarbonate, 30 parts of titanium dioxide, 20 parts of MBS, 20 parts of ABS, 15 parts of silane coupling agent, 6 parts of silicone , 6 parts of paraffin, 5 parts of phthalocyanine pigment masterbatch, wherein the particle size of titanium dioxide is 0.1 micron.

[0047] The preparation method of the polycarbonate composite material of the present embodiment, comprises the following steps:

[0048] (1) drying the components of the above proportioning ratio at 80° C. for 8 hours to obtain a component with a moisture content lower than 0.02% after drying;

[0049] (2) Stir the dried inorganic particles, compatibilizer and lubricant in an anchor stirrer at 110°C at 150r / min for 2min, then at 350r / min for 3min and mix evenly;

[0050] (3) Stir the mixture of step (2) and the dried organic toughening agent at a temperature of 110°C at 200r / min for 5min in a hinged sti...

Embodiment 3

[0054] The polycarbonate composite material of this embodiment includes: by weight, 105 parts of bisphenol A polycarbonate, 15 parts of aliphatic polycarbonate, 39 parts of mica, 1 part of carbon nanotube, 10 parts of polyurethane elastomer, 50 parts of silane coupling agent, 10 parts of silicone, 10 parts of paraffin and 3 parts of phthalocyanine pigment masterbatch, among which, the mica is 0.1 micron, the inner diameter of carbon nanotube is 1-2 nanometers, the outer diameter is 3-4 nanometers, and the length is 50 Microns.

[0055] The preparation method of the polycarbonate composite material of the present embodiment, comprises the following steps:

[0056] (1) drying the components of the above proportioning ratio at 120° C. for 12 hours to obtain a component with a moisture content lower than 0.02% after drying;

[0057] (2) Stir the dried inorganic particles, compatibilizer and lubricant in an anchor stirrer at 120°C at 200r / min for 2min, then at 400r / min for 3min an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com