Wear-resistant melamine impregnated paper, preparation method and application thereof

A technology of melamine and rubber-impregnated paper, which is applied in the field of decorative materials, can solve problems such as complicated operation steps, lower production efficiency, and easy damage to steel plates, and achieve the effects of simple operation steps, improved production efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

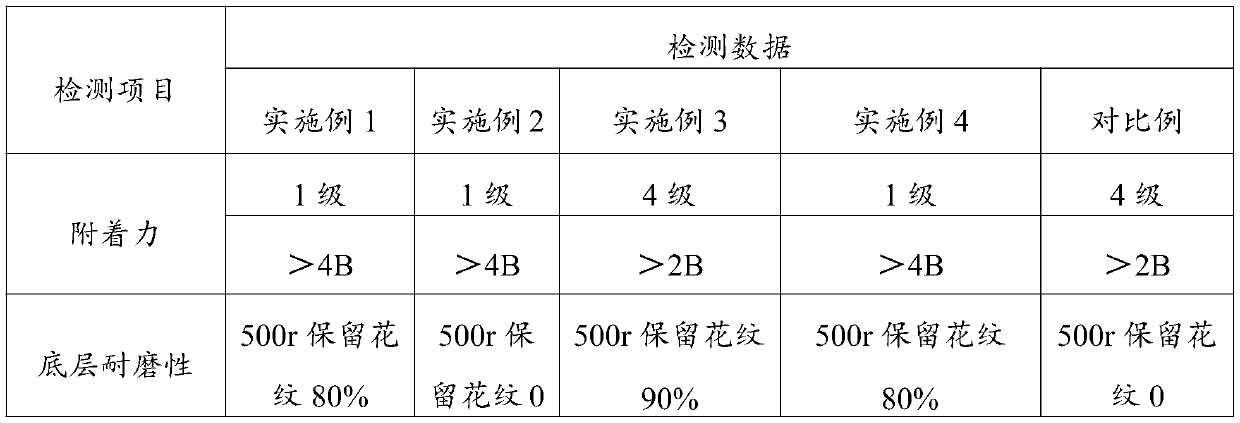

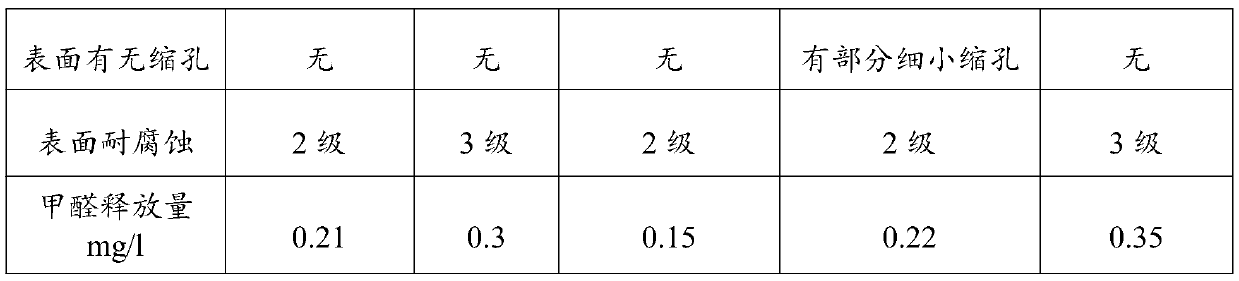

Embodiment 1

[0057] Preparation of wear-resistant melamine impregnated paper:

[0058] Step 1: dipping, first by weight 185 parts of melamine, 190 parts of formaldehyde solution, 5 parts of caprolactam, 2 parts of triethanolamine, 8 parts of diethylene glycol, 90 parts of water, 0.96 parts of curing agent (morpholine 0.16, para Toluenesulfonic acid 0.32 and water 0.48), release agent 0.96 part and dedusting agent 1.44 part are mixed and prepared into melamine resin, then printing paper is impregnated in described melamine resin;

[0059] Step 2: The first step is drying, and the printing paper impregnated with melamine resin in step 1 is taken out, and the dry weight of the melamine resin impregnated on the printing paper is controlled to be 180g / m when taken out 2 , and then dried at 150°C;

[0060] Step 3: Coating a wear-resistant melamine resin layer on one side of the printing paper impregnated with melamine resin, and coating the melamine resin prepared in step 1 on the other side, a...

Embodiment 2

[0066] Preparation of melamine impregnated paper with polyurethane primer layer:

[0067] Step 1: dipping, first by weight 200 parts of melamine, 200 parts of formaldehyde solution, 7 parts of caprolactam, 3 parts of triethanolamine, 5 parts of diethylene glycol, 85 parts of water, 1 part of curing agent (morpholine 1 / 6 , 1 / 3 of p-toluenesulfonic acid and 1 / 2 of water), 1 part of mold release agent and 1.5 parts of dust remover are mixed to prepare melamine resin, and then the printing paper is impregnated in the melamine resin;

[0068] Step 2: The first step is drying, and the printing paper impregnated with melamine resin in step 1 is taken out, and the dry weight of the melamine resin impregnated on the printing paper is controlled to be 160g / m when taken out 2 , and then dried at 140°C;

[0069] Step 3: one side of the printing paper impregnated with melamine resin is coated with polyurethane resin, and the other side is coated with the melamine resin prepared in step 1,...

Embodiment 3

[0075] Preparation of wear-resistant melamine impregnated paper (without polyurethane primer layer):

[0076] Step 1: dipping, first by weight 150 parts of melamine, 180 parts of formaldehyde solution, 10 parts of caprolactam, 3 parts of triethanolamine, 7 parts of diethylene glycol, 80 parts of water, 0.86 parts of curing agent (morpholine 0.14, para 0.29 parts of toluenesulfonic acid and 0.43 parts of water), 0.86 parts of release agent and 1.29 parts of dedusting agent are mixed and prepared into melamine resin, and then the printing paper is impregnated in the melamine resin;

[0077] Step 2: The first step is drying, and the printing paper impregnated with melamine resin in step 1 is taken out, and the dry weight of the melamine resin impregnated on the printing paper is controlled to be 125g / m when taken out 2 , and then dried at 130°C;

[0078] Step 3: one side of the printing paper impregnated with melamine resin is coated with a wear-resistant melamine resin layer, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com