Method for treating quicksand in digging hole of manual digging pile by light well point dewatering

A technology of manually digging hole piles and light well points, which is applied in infrastructure engineering, construction, etc., to achieve the effects of improving construction efficiency, fast precipitation, and universal principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings

[0058] 1. A light well point dewatering device for treating quicksand in holes dug by manual digging piles

[0059] 1. Punching device

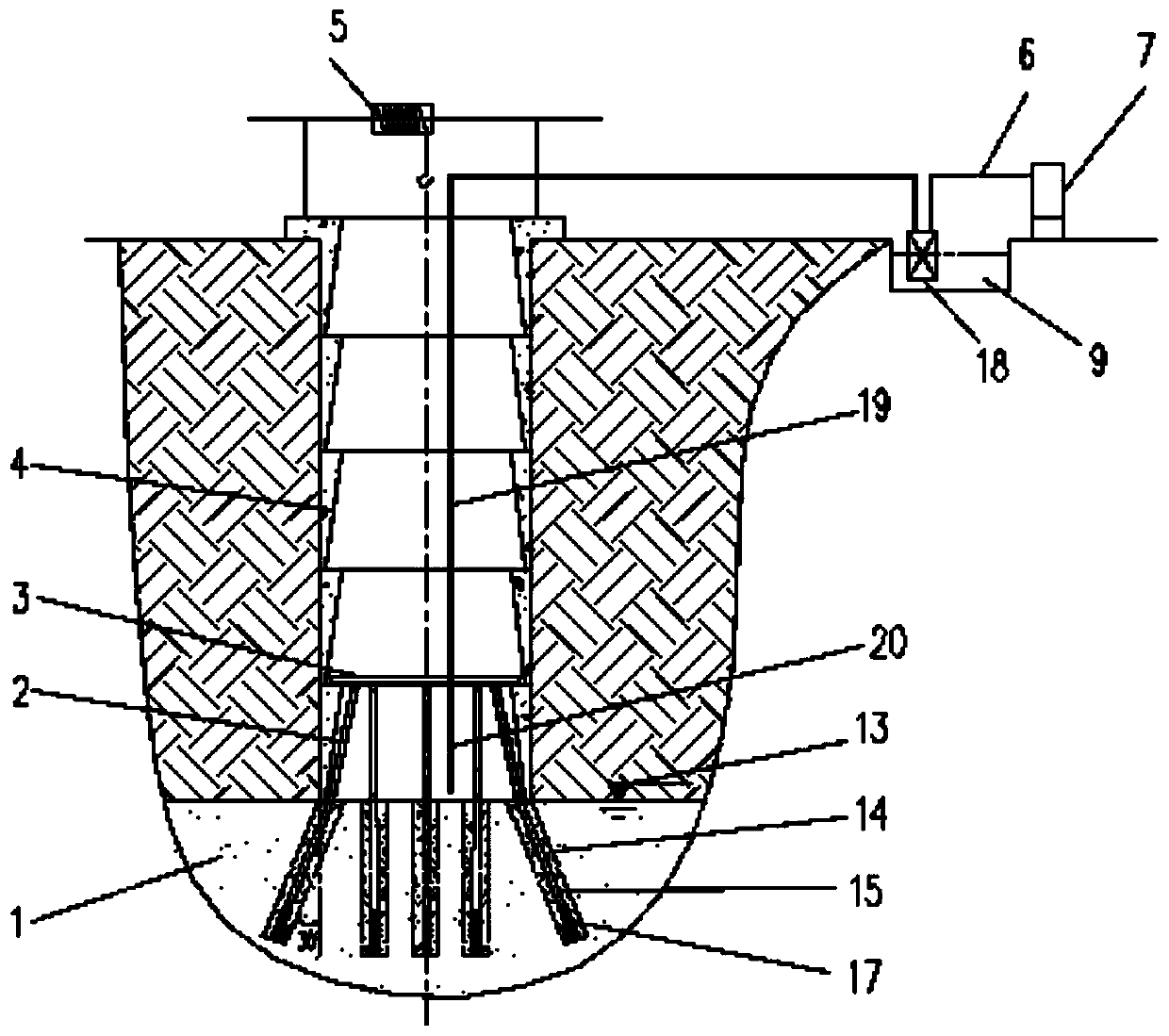

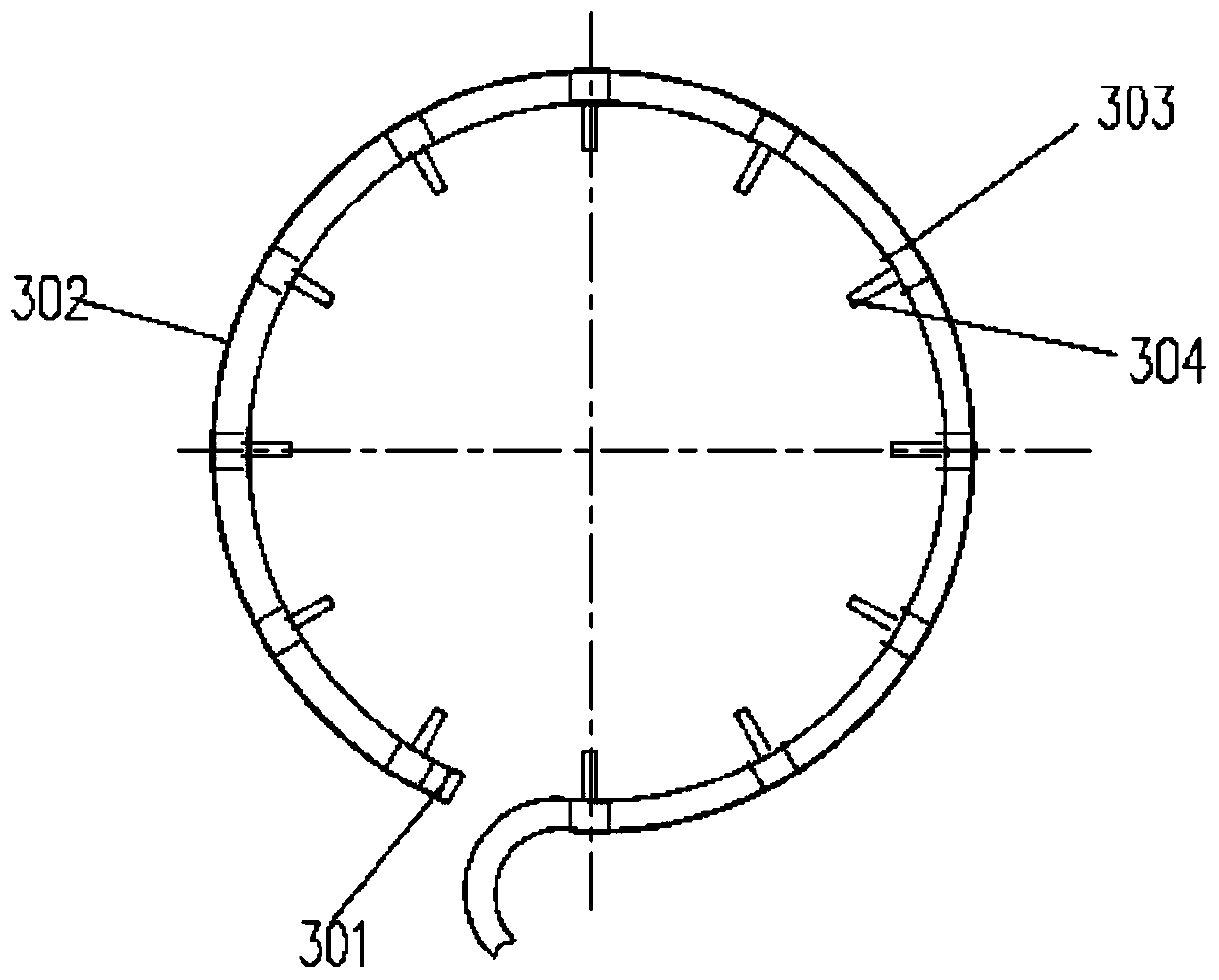

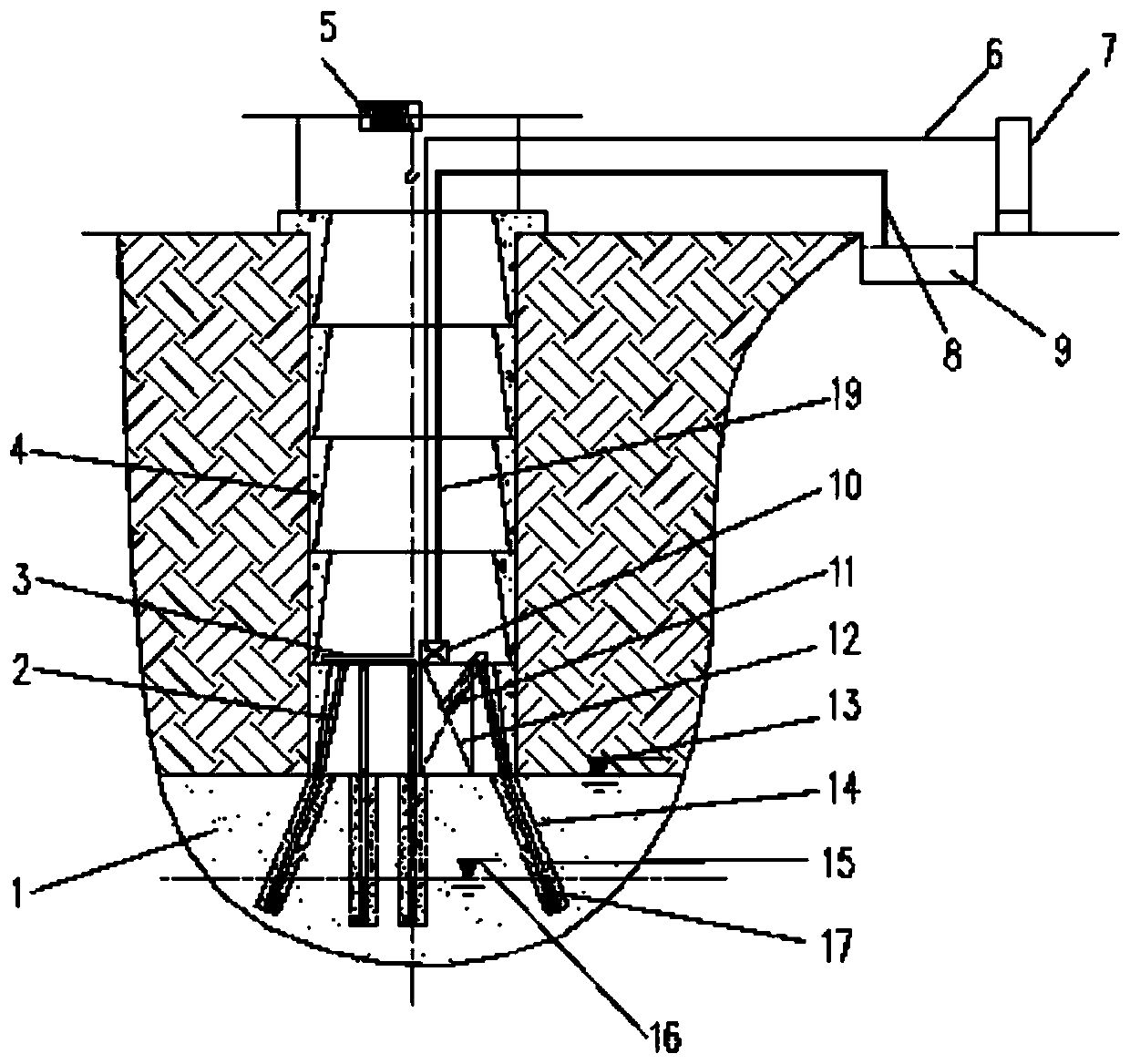

[0060] Such as figure 1 As shown, the punching device and layout schematic diagram for processing quicksand in the present invention. Punching device for quicksand treatment, including connecting pipe 2, flexible water collection pipe device 3, winch 5, cable wire 6, power distribution cabinet 7, water storage tank 9, well point pipe 14, washed sand 15, water filter pipe 17, small water delivery Submersible pump 18, water supply pipe 19, punching steel pipe 20; Described winch 5 is arranged on the ground of the hole-digging pile aperture, and winch 5 is used for excavating in the hole of digging pile and conveying equipment to the bottom of the hole, and digging the hole , Concrete wall protection operation...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap