Wet dicyandiamide pneumatic conveying device

A technology of wet material and pneumatic conveying of dicyandiamide, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of poor fluidity, manpower dredging, time-consuming and labor-intensive, etc., so as to reduce production costs and simplify material transportation. Process, the effect of solving the material blockage of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

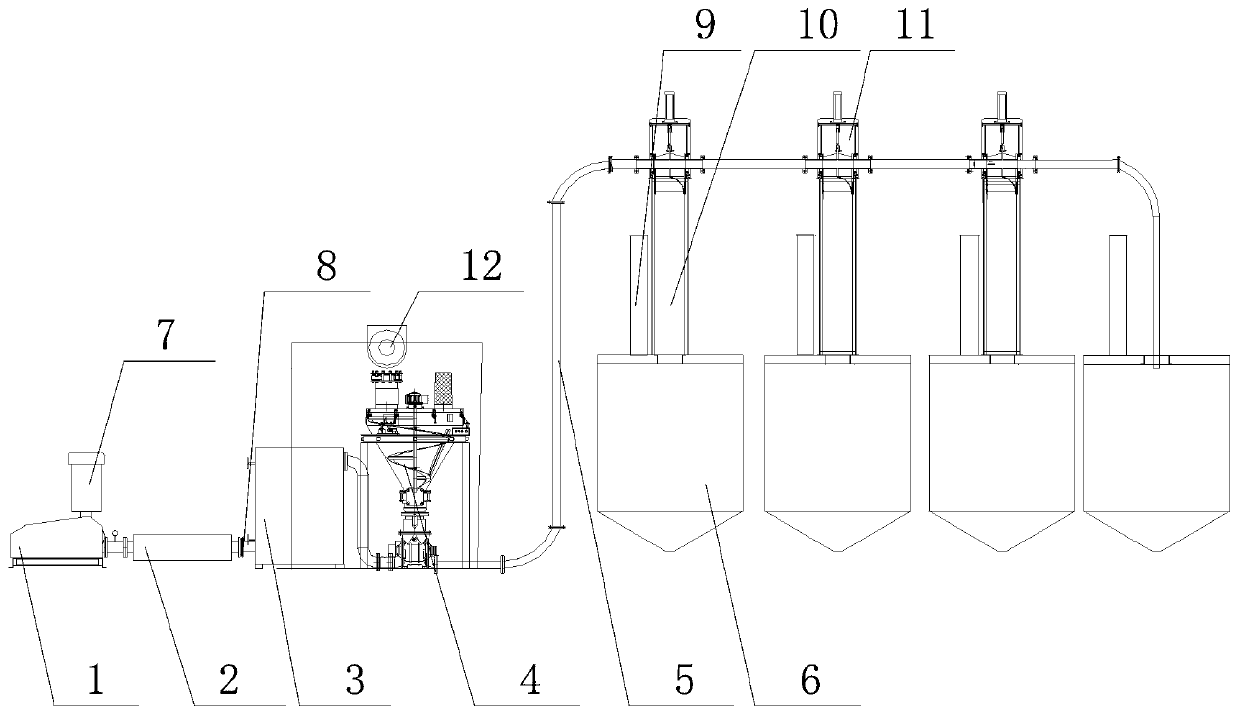

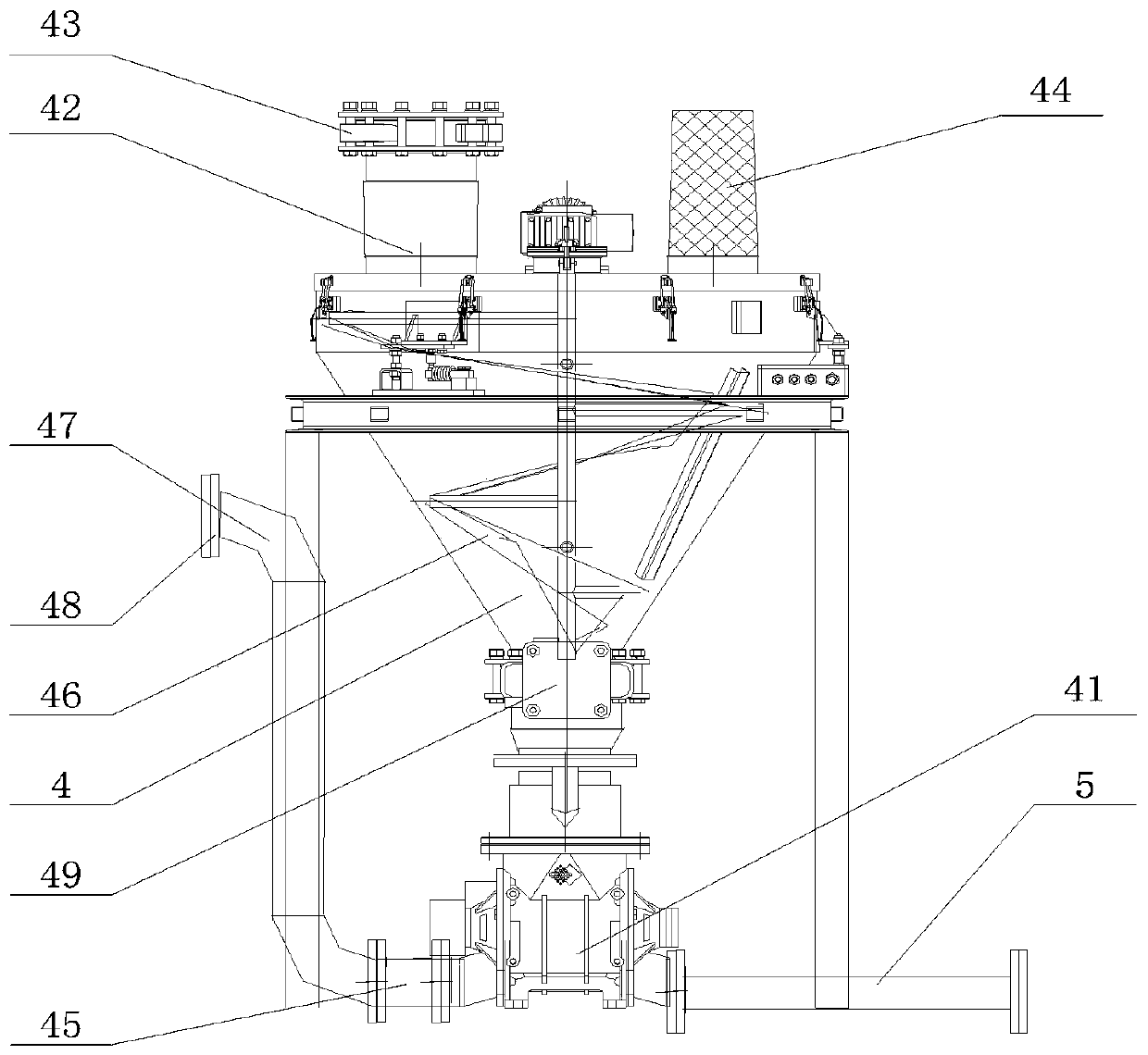

[0025] Such as Figure 1-2As shown, a dicyandiamide wet material pneumatic conveying device includes a Roots blower 1, a heater 3, and a quantitative silo 4. The outlet of the Roots blower 1 is provided with an outlet silencer 2, and the outlet silencer 2 is provided with an air outlet 8, the air outlet 8 is connected with the heater 3, the top of the quantitative feed bin 4 is connected with the shaftless screw conveyor 12, and the top of the quantitative feed bin 4 is provided with a feed inlet 42. The feed port 42 and the shaftless screw conveyor 12 are connected by a pneumatic flapper valve A43, and the lower part of the quantitative silo 4 is provided with a pneumatic flapper valve B49, and the pneumatic flapper valve B49 is connected to the lower part The set direct blowing rotary feeding valve 41 is connected together, and the direct blowing rotary feeding valve 41 is connected with the air extraction pipeline 5 below, and the front end of the air extraction pipeline 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com