Safe and reliable flexible CIGS solar module high-voltage resistance test equipment

A technology for solar modules and testing equipment, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. High sensitivity and the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

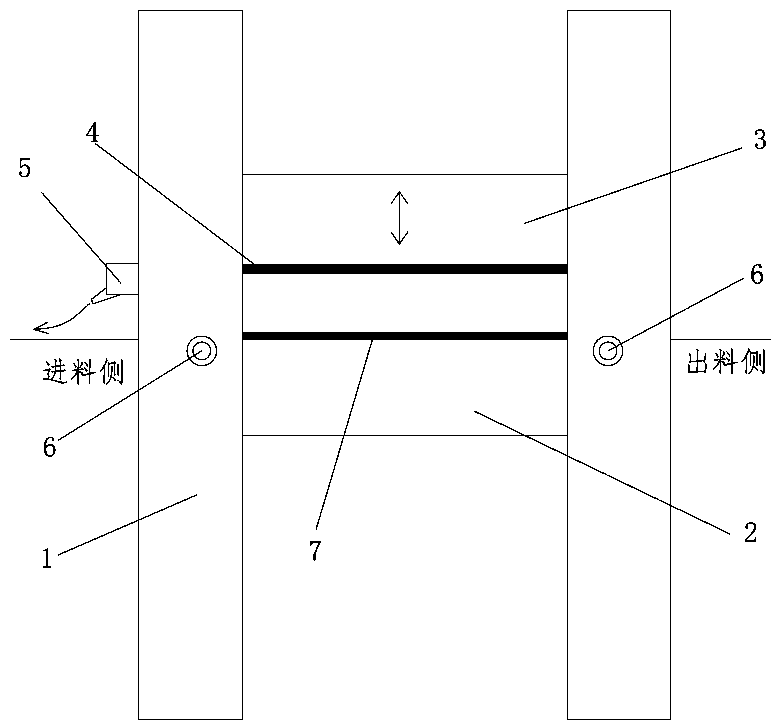

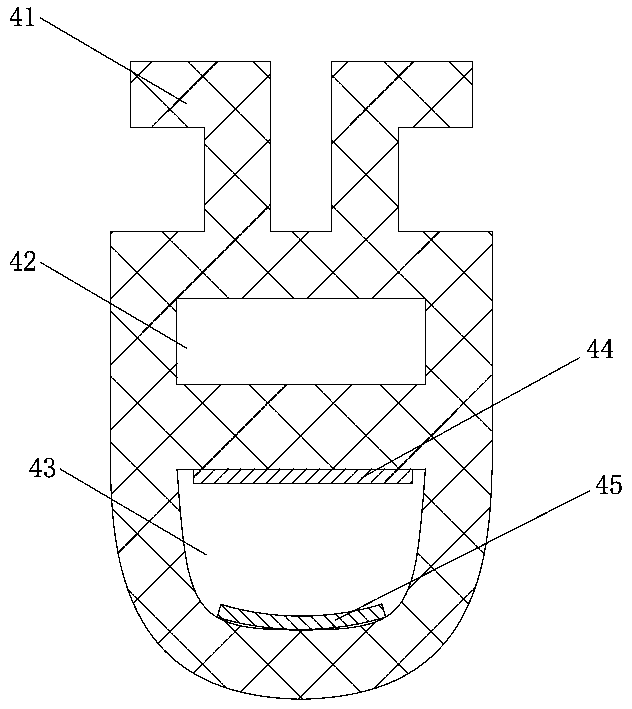

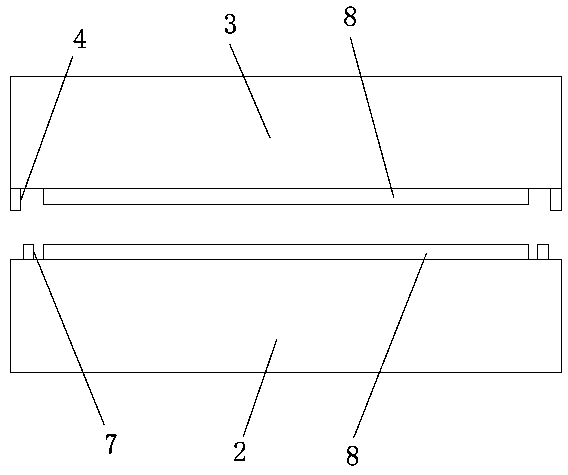

[0021] Embodiment: A safe and reliable flexible CIGS solar module high voltage test equipment, such as figure 1 As shown, a frame 1 is included, the frame 1 is provided with a test platform 2, a liftable pressing plate 3 is arranged above the testing platform, and an anti-pinch insulating strip 4 is embedded around the bottom surface of the pressing plate. The lower insulating strip 7 is arranged around the test platform 2, and the anti-pinch insulating strip and the lower insulating strip are provided with internal and external misalignment. The upper surface of the test platform 2 and the lower surface of the pressure plate are flexible carbon fiber conductive layers 8, and the flexible carbon fiber conductive layers use graphite felt or conductive cotton.

[0022] A pair of linkage switches 6 are arranged on the racks on both sides of the test platform, and a pair of linkage switches 6 can be pressed down at the same time to start the lowering of the pressure plate. The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com