Germanium-containing styrene derivative monomer and preparation method thereof, functionalized polyolefin containing germanium-styrene derivative and use thereof

A technology of styrene derivatives and functionalized polyolefins, applied in the field of olefin polymerization, can solve the problem of inability to popularize polarization, and achieve the effects of wide practicability and industrialization prospects, mild reaction conditions and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Maleic anhydride-styrene alternating copolymer grafted ethylene propylene rubber

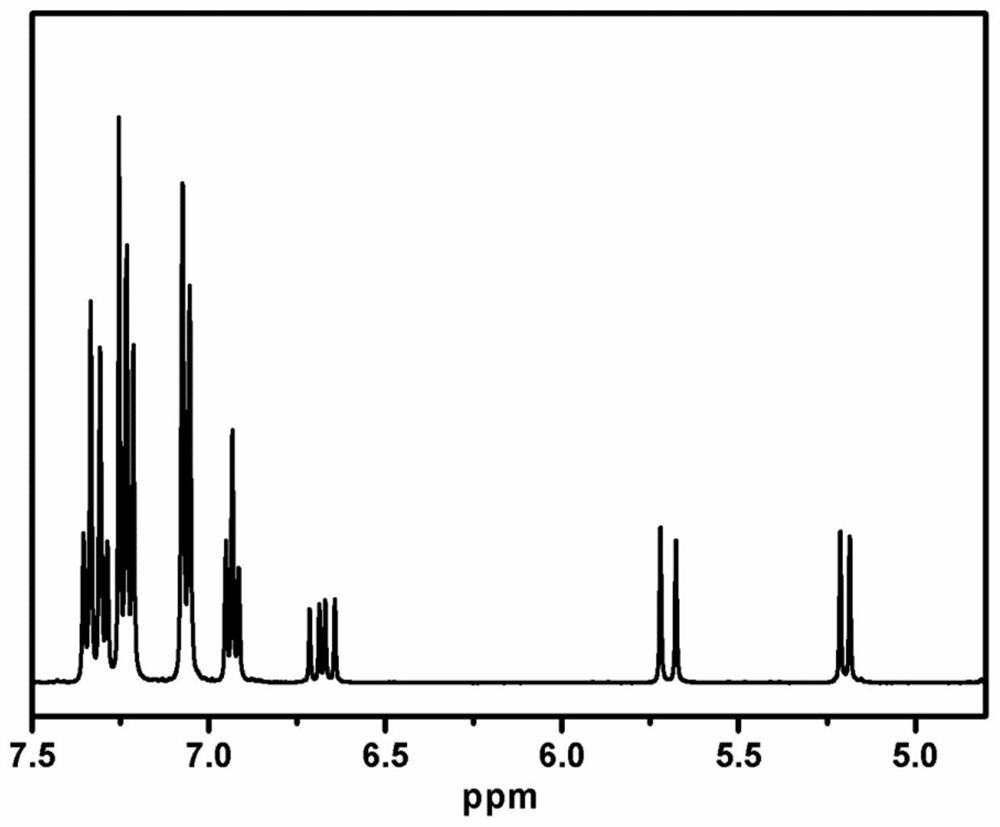

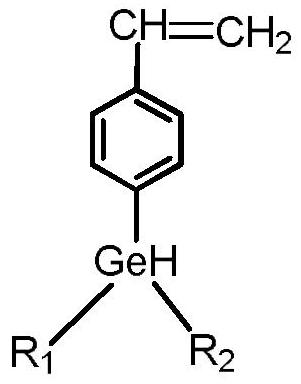

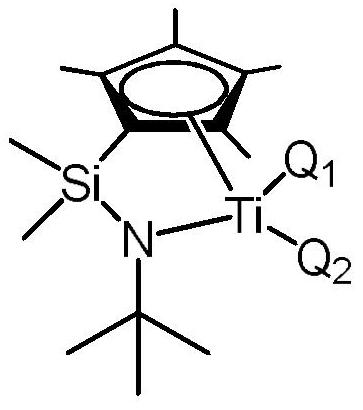

[0051] 5g of 4-diphenylgermanium styrene monomer was weighed and dissolved in 250g of toluene solution, and then the solution was transferred to a 500ml reaction kettle and stirred evenly, while the temperature of the reaction kettle was raised to 120°C. Feed 20g of ethylene and 10g of propylene into the reaction kettle, then add 600umol of MAO and 2umol of Ti-based catalyst into the reaction kettle to initiate a polymerization reaction, and react for 5min. 2 g of the reaction solution was added to ethanol to obtain 4-diphenylgermanyl styrene functionalized ethylene-propylene rubber. Add 5g of styrene and 5g of maleic anhydride to the remaining reaction solution, at the same time increase the polymerization temperature to 180°C, continue the reaction for 4h, after the reaction is completed, add 300g of ethanol to the above reaction solution to terminate the reaction to obtain so...

Embodiment 2

[0054] Example 2 Maleic anhydride-styrene alternating copolymer grafted linear low density polyethylene

[0055] 5g of 4-diphenylgermanium-based styrene monomer and 5g of 1-butene were added to 250g of toluene solution, then the solution was transferred to a 500ml reactor and stirred evenly, while the temperature of the reactor was raised to 120°C. Feed 30g of ethylene into the reaction kettle, then add 600umol of MAO and 2umol of Ti-based catalysts into the reaction kettle to initiate a polymerization reaction, and react for 5min. 2 g of the reaction solution was taken and added to ethanol to obtain 4-diphenylgermanyl styrene functionalized linear low density polyethylene. Add 5g of styrene and 5g of maleic anhydride to the remaining reaction solution, at the same time increase the polymerization temperature to 180°C, continue the reaction for 4h, after the reaction is completed, add 300g of ethanol to the above reaction solution to terminate the reaction to obtain a solid pr...

Embodiment 3

[0058] Example 3 Maleic anhydride-styrene alternating copolymer grafted polyolefin elastomer

[0059] Dissolve 5g of 4-diphenylgermanium styrene monomer in 300ml of toluene solution, then transfer the above solution to a 500ml reaction kettle and stir evenly. 20 g of 1-octene was added to the autoclave via a syringe while the autoclave temperature was raised to 120°C. Feed 30g of ethylene into the reaction kettle, then add 600umol of MAO and 2umol of Ti-based catalysts into the reaction kettle to initiate a polymerization reaction, and react for 5min. 2 g of the reaction solution was added into ethanol to obtain a 4-diphenylgermanyl styrene functionalized polyolefin elastomer. Then 5g of styrene and 5g of maleic anhydride were added to the remaining reaction solution, and the polymerization temperature was raised to 180°C, and the reaction was continued for 4h. After the reaction was completed, 300g of ethanol was added to the above reaction solution to terminate the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com