Secondary amide polyamine quaternary ammonium salt amphoteric asphalt emulsifier and preparation method thereof

A secondary amide polyamine quaternary ammonium salt, the secondary amide polyamine quaternary ammonium salt technology, applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds and other directions, can solve the high cost of emulsifier raw materials, production experiments The problems of high equipment requirements and high cost can achieve the effect of good aggregate adhesion and storage stability, excellent performance indicators, and enhanced charge strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] For above asphalt emulsifier, the present invention also provides its preparation method, comprises the following steps:

[0041] (1) Polyethylene polyamine, alcohol solvent and acrylic acid are mixed and reacted to obtain reaction intermediate I, and the general structural formula of said reaction intermediate I is:

[0042] NH 2 (C 2 h 4 NH) n CH 2 CH 2 COOH,

[0043] Among them, n=2-4;

[0044] (2) Add epichlorohydrin gradually again in reaction intermediate I, mixed reaction, obtain reaction intermediate II, the general structural formula of described reaction intermediate II is:

[0045] ClCH 2 CH(OH)CH 2 NH(C 2 h 4 NH) n CH 2 CH 2 COOH,

[0046] Among them, n=2-4;

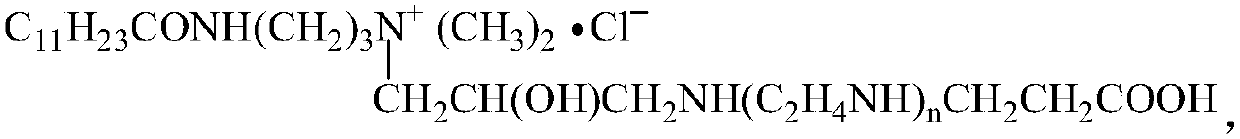

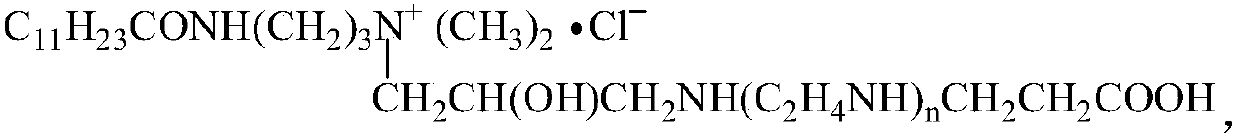

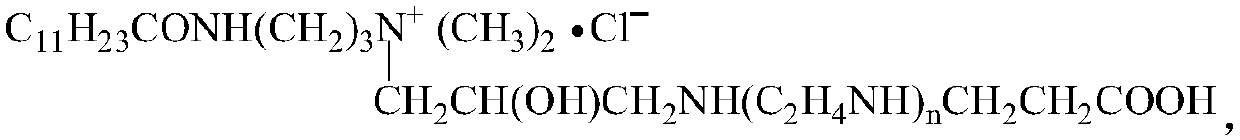

[0047] (3) Gradually add cocoyl propyl dimethyl tertiary amine to the reaction intermediate II, mix and react, then add water, mix and react, and obtain the secondary amide polyamine quaternary ammonium salt amphoteric asphalt emulsifier.

[0048] In some preferred technical schemes of...

Embodiment 1

[0069] (1) Preparation of secondary amide polyamine quaternary ammonium salt amphoteric asphalt emulsifier (n=4):

[0070] 1) Add 208.45g of tetraethylenepentamine and 300g of isopropanol into the reactor, heat and stir to mix. Then gradually added 79.3g of acrylic acid, and stirred at 75°C for 2h to obtain reaction intermediate I.

[0071] 2) Gradually add 97.07 g of epichlorohydrin to the reaction intermediate I. After the addition is complete, react at 75° C. for 2 hours to obtain the reaction intermediate II.

[0072] 3) Gradually add 284.5 g of cocoyl propyl dimethyl tertiary amine to the reaction intermediate II. After the addition is complete, react at 75° C. for 0.5 h, then add 300 g of water. After adding water, react at 75° C. for 3 h. The secondary amide polyamine quaternary ammonium salt amphoteric asphalt emulsifier was obtained, which was reserved for the emulsified asphalt test.

[0073] The synthesized product was separated and purified by recrystallization a...

Embodiment 2

[0083] (1) Preparation of secondary amide polyamine quaternary ammonium salt amphoteric asphalt emulsifier (n=3):

[0084] 1) Add 160.9g triethylenetetramine and 300g isopropanol into the reactor, heat and stir to mix. Then gradually added 79.3g of acrylic acid, and stirred at 75°C for 2h to obtain reaction intermediate I.

[0085] 2) Gradually add 97.07 g of epichlorohydrin to the reaction intermediate I. After the addition is complete, react at 75° C. for 2 hours to obtain the reaction intermediate II.

[0086] 3) Gradually add 284.5g cocoyl propyl dimethyl tertiary amine to the reaction intermediate II. After the addition is complete, react at 75°C for 0.5h, then add 300g of water. After adding water, react at 75°C for 3h. The secondary amide polyamine quaternary ammonium salt amphoteric asphalt emulsifier was obtained, which was reserved for the emulsified asphalt test.

[0087] The synthesized product was separated and purified by recrystallization and then detected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com