Structure of anti-ultraviolet transparent power generation glass and preparation method thereof

An anti-ultraviolet and glass technology, applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of limited protection, poor transparency, and no protective effect of ultraviolet light, so as to prevent damage and solve the effect of visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

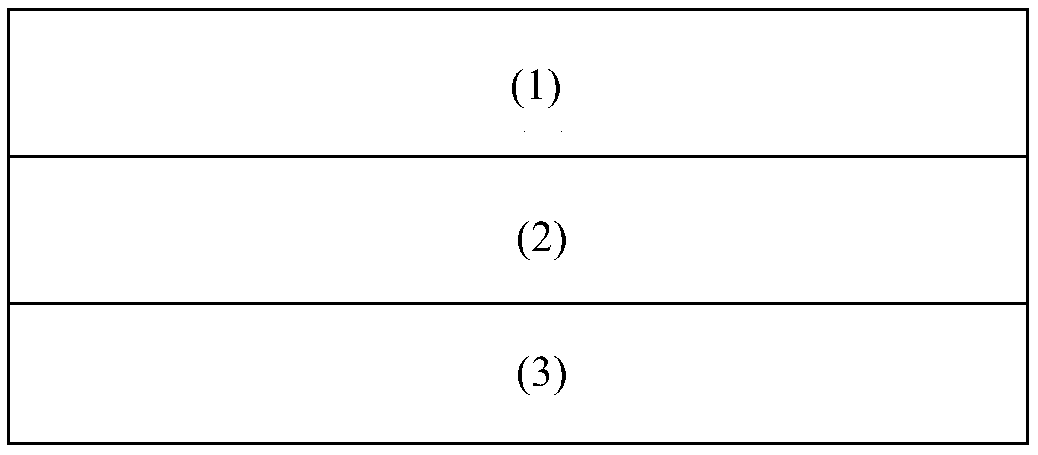

Image

Examples

Embodiment 1

[0018] 1. Treat the FTO glass whose square resistance is 5-20Ω / □ sheet resistance with ultrasonic wave, and perform chemical cleaning with isopropanol, acetone and deionized water.

[0019] 2. A 250 nm thick ZnO film was deposited on the FTO-coated glass using an RF sputtering system.

[0020] 3. Deposit a layer of metallic nickel on ZnO by DC sputtering.

[0021] 4. Put the substrate deposited with metal nickel into the RTP return furnace to oxidize in an oxygen atmosphere, the temperature is 200-700 degrees Celsius (600 degrees Celsius here), and the time is 10-60min (40min here). Make the metal Nickel is oxidized to nickel oxide.

[0022] 5. ITO was prepared on nickel oxide by magnetron sputtering technology.

Embodiment 2

[0024] 1. The square resistance is FTO glass with a sheet resistance of 5-20Ω / □, treated with ultrasonic waves, and chemically cleaned with isopropanol, acetone and distilled water;

[0025] 2. A 250 nm thick ZnO film was deposited on the FTO-coated glass using an RF sputtering system.

[0026] 3. Depositing a nickel oxide film with a thickness of 40 nm on the ZnO by direct current sputtering.

[0027] 4. ITO was prepared on nickel oxide by magnetron sputtering technology.

Embodiment 3

[0029] 1. The square resistance is FTO glass with a sheet resistance of 5-20Ω / □, treated with ultrasonic waves, and chemically cleaned with isopropanol, acetone and distilled water;

[0030] 2. A 250 nm thick ZnO film was deposited on the FTO-coated glass using the spin-coating method.

[0031] 3. Depositing a nickel oxide film with a thickness of 40 nm on the ZnO by direct current sputtering.

[0032] 4. ITO was prepared on nickel oxide by magnetron sputtering technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com