Preparation and application of pH-responsive natural plant oil-water separation filter membrane

A vegetable oil, responsive technology, applied in the field of membrane separation, can solve the problems of insufficient resistance to liquid penetration, reduced practicability of filter membranes, low resistance to liquid penetration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

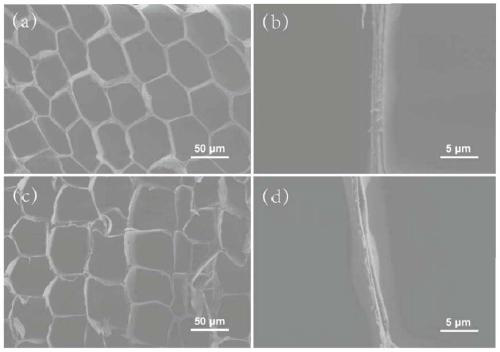

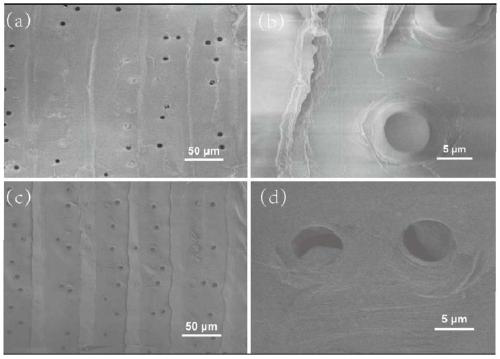

[0063] The pH-responsive natural vegetable oil-water separation filter membrane provided by the present invention and its preparation method specifically include the following steps:

[0064] (1) Use a circular saw to cut the plant stem into a wood film with a diameter of 1-10 cm and a thickness of 0.5-3 mm.

[0065] The stem is paulownia, pine, cypress, fir, poplar, willow, basswood, elm or basswood.

[0066] (2) After using 20ml of solvent for ultrasonic extraction for a certain period of time, dry at 60°C for 30min.

[0067] The washing solvent is any one of methanol, ethanol, acetone, propanol, tetrahydrofuran or isopropanol, each time is 5 min, and the number of times is 3 times.

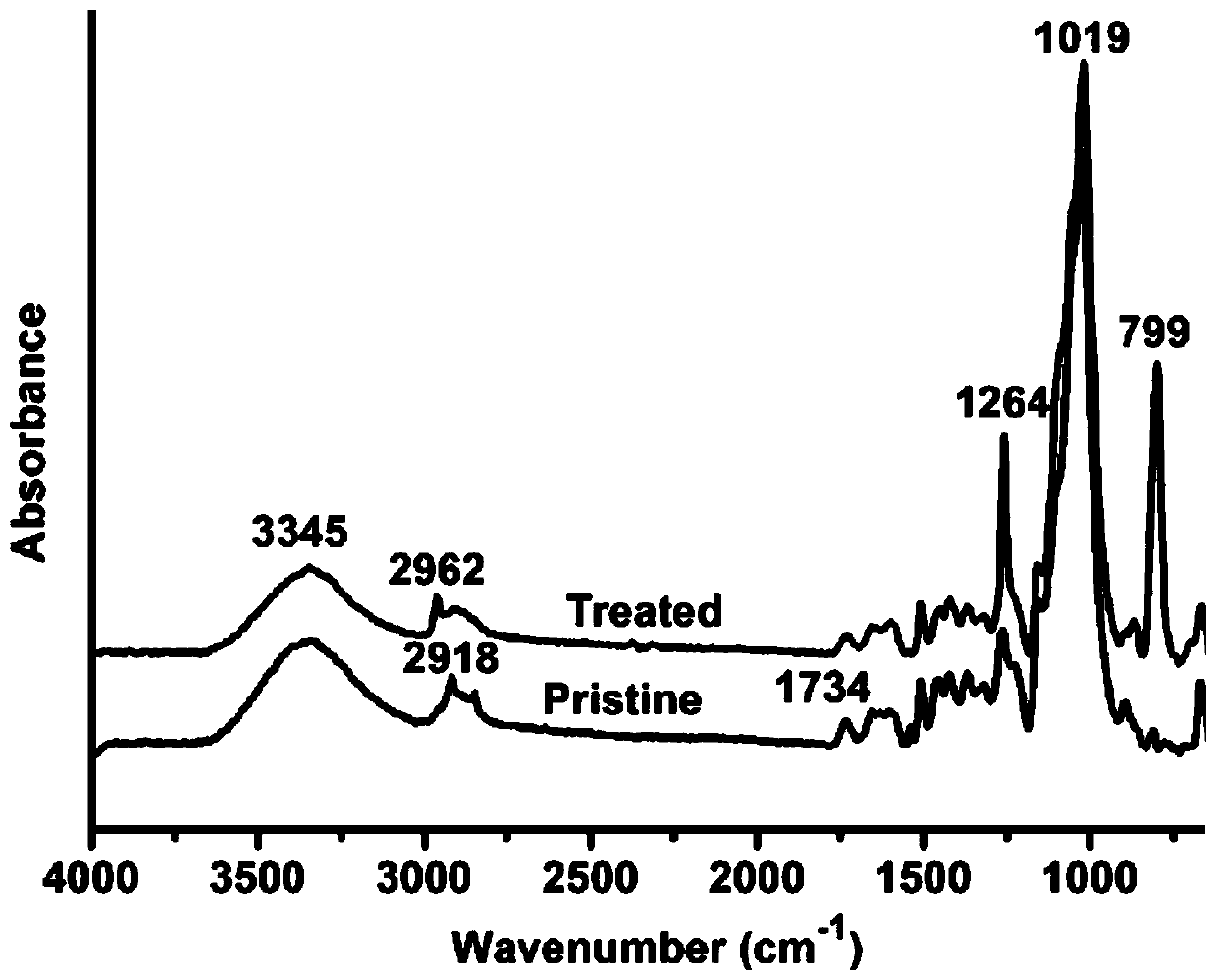

[0068] (3) The treated wood film was heated in silicone oil, and the silicone oil was washed with 20 ml of solvent each time, washed three times, and dried at 60° C. for 30 minutes.

[0069] The silicone oil is any one of methyl silicone oil, dimethyl silicone oil, phenyl methyl silicone oil ...

Embodiment 1

[0077] Preparation of a pH-responsive natural vegetable oil-water separation membrane:

[0078] 1. Use a wood saw to cut the fir into a wood film with a diameter of 3mm and a thickness of 1.0mm.

[0079] 2. Ultrasonic extraction of wood film in ethanol, the amount of extraction solvent is 20ml, each ultrasonic time is 5min, the number of times is 3 times, and it is dried at 60°C for 30min.

[0080] 3. Then heat in 80°C silicone oil for 2h, wash the silicone oil with 20ml of dimethyl ether each time, wash 3 times, and dry at 60°C for 30min.

[0081] 4. Finally, use 0.2mol / L NaOH solution to soak at room temperature for 10 minutes, and use 0.2mol / L hydrochloric acid for 10 minutes, and dry for 2 hours to obtain the pH-responsive fir oil-water separation filter membrane.

[0082] Application of a pH-responsive natural vegetable oil-water separation membrane:

[0083] like Figure 9 As shown, the treated wood membrane can switch its wettability to water under oil in acidic and ...

Embodiment 2

[0085] Preparation of a pH-responsive natural vegetable oil-water separation membrane:

[0086] 1. Use a wood saw to cut Paulownia into a wood film with a diameter of 4mm and a thickness of 1.5mm.

[0087] 2. Ultrasonic extraction of wood film in acetone, the amount of extraction solvent is 20ml, each ultrasonic time is 5min, the number of times is 3 times, and it is dried at 60°C for 30min.

[0088] 3. Then heat in silicone oil at 100°C for 1.5h, wash the silicone oil with 20ml of methyl ethyl ketone each time, wash three times, and dry at 60°C for 30min.

[0089] 4. Finally, use 0.5mol / L NaOH solution to soak at room temperature for 15 minutes, and use 0.5mol / L hydrochloric acid to soak for 15 minutes, and dry for 2 hours for the controllable separation of light oil / water / heavy oil three-phase oil-water mixture.

[0090] Application of a pH-responsive natural vegetable oil-water separation membrane:

[0091]The filter membrane prepared by the above method is clamped betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com