Catalytic membrane, preparation method and application thereof

A catalytic membrane and base membrane technology, applied in the field of membrane materials, can solve the problems of increasing cleaning costs, limiting the application scope of membrane materials, affecting the properties of liquid components, etc., to achieve self-cleaning, anti-pollution, and reducing adhesion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a catalytic membrane, the preparation method is as follows:

[0074] (1) Dissolve tannic acid and ferric chloride in 10mM Tris-HCl buffer solution (pH is 8.5) respectively, prepare the tannic acid solution with a concentration of 4g / L and the trichlorohydrin solution with a concentration of 2g / L ferric chloride solution; place the basement membrane (polyethersulfone nanofiltration membrane with a molecular weight cut-off of 1000Da) in the filter forward, wet the membrane surface with 10mL ferric chloride solution for 3min, then add 10mL tannic acid solution, React at room temperature for 1 min at 100 rpm to obtain a mixed coating of tannic acid and ferric chloride on the surface of the base film; shake it with deionized water at 150 rpm for 1 h to wash off excess reaction solution;

[0075] (2) Place the polyglutamic acid solution (solvent being 10mM Tris-HCl buffer solution, pH 8.5) with a concentration of 2g / L on the basement membrane with the...

Embodiment 2

[0079] The present embodiment provides a kind of catalytic membrane, and the difference of its preparation method and embodiment 1 is only, the polyglutamic acid in the step (2) is replaced with the glutamic acid of equal mass.

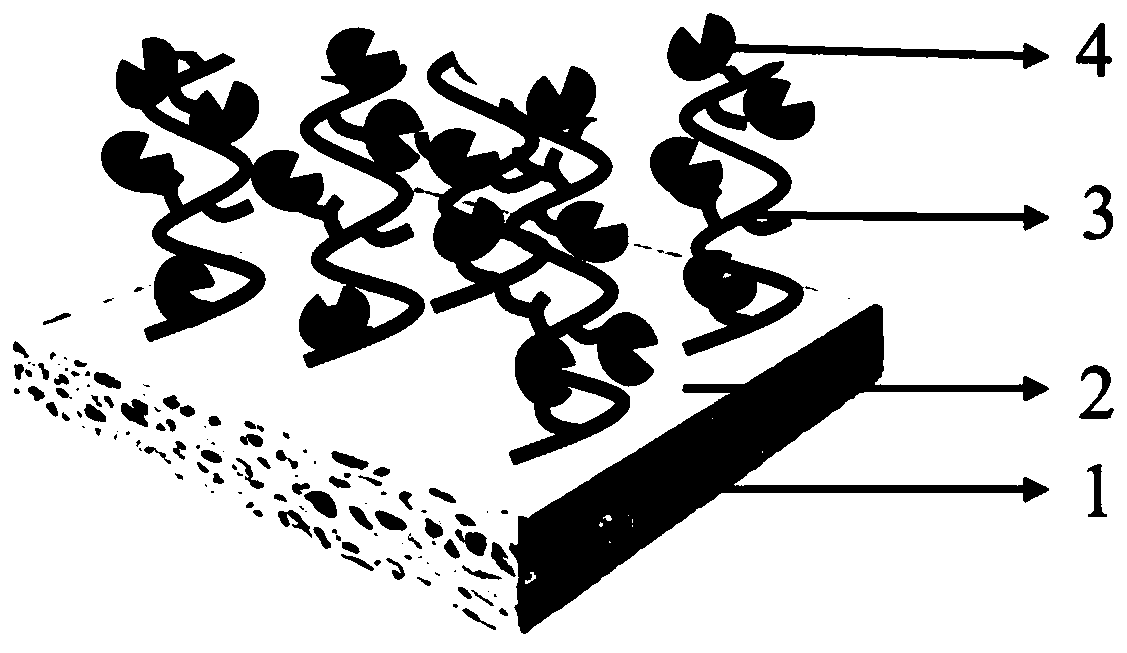

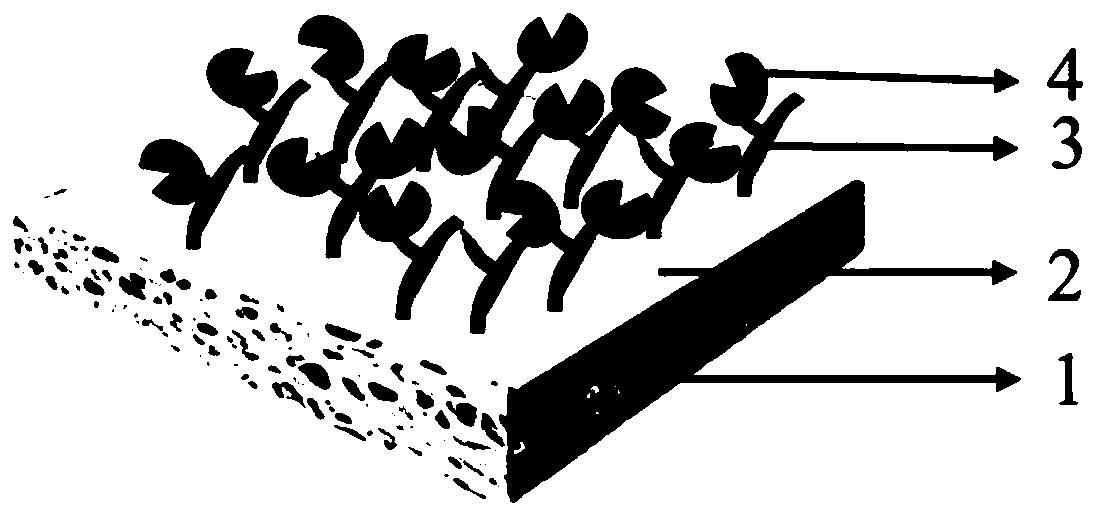

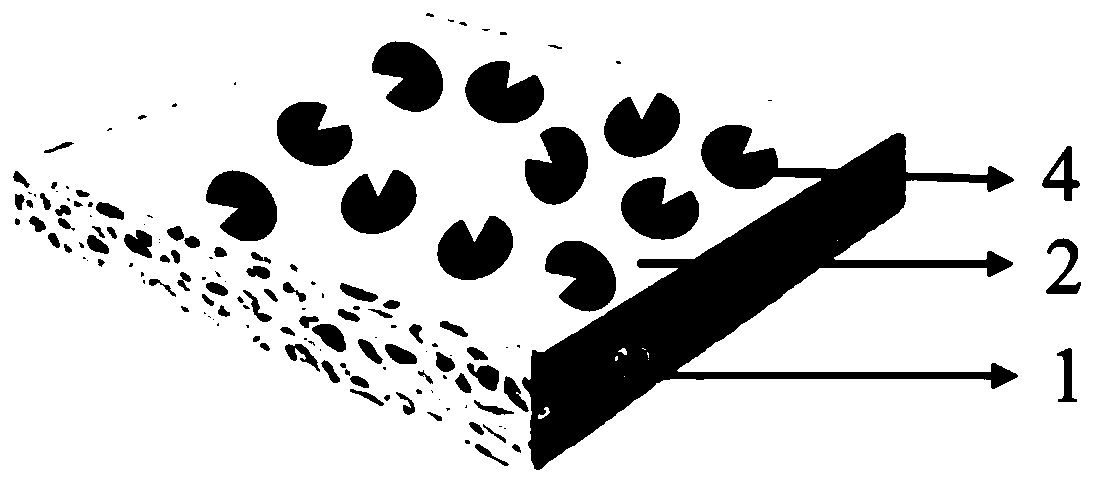

[0080] The schematic diagram of the structure of the catalytic membrane obtained in this embodiment is as follows: figure 2 Shown, wherein, 1 is base film, 2 is the mixed coating of tannic acid and ferric chloride, 3 is hydrophilic active substance (glutamic acid), 4 is enzyme.

Embodiment 3

[0082] This embodiment provides a catalytic membrane, the difference between its preparation method and embodiment 1 is that the polyglutamic acid in step (2) is replaced with polyaspartic acid of equal mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com