Preparation method of ordered mesoporous MgNi/WO3 methanation catalyst

A methanation catalyst and catalyst technology, which can be used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, carbon compound catalysts, etc., and can solve the problems of low catalyst activity and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

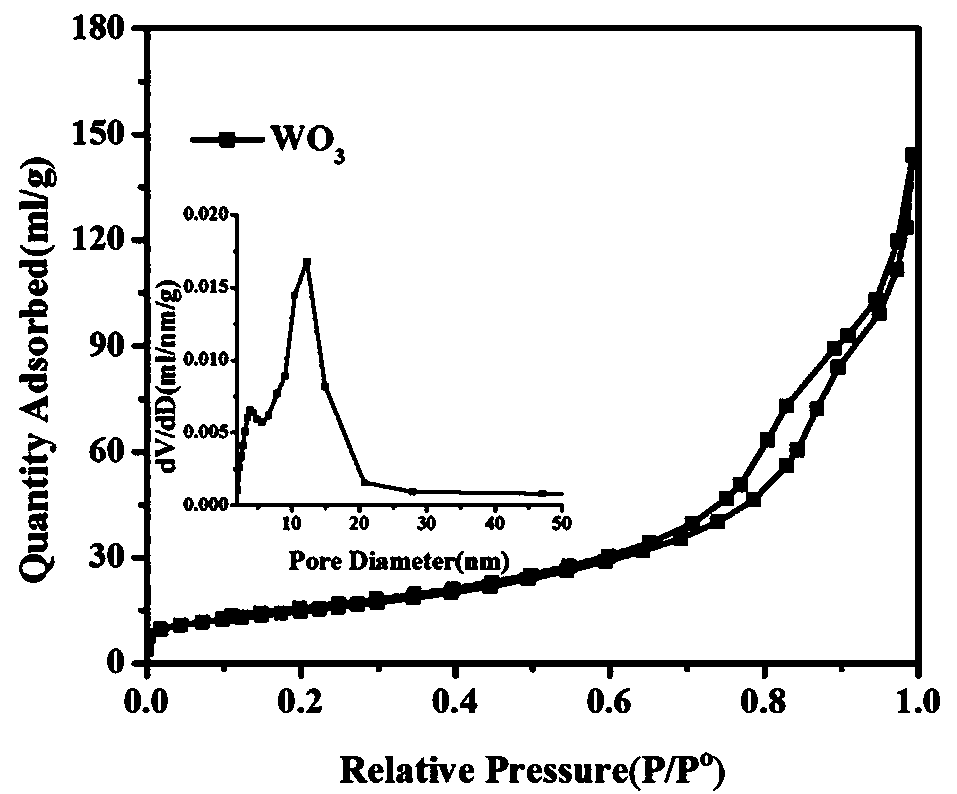

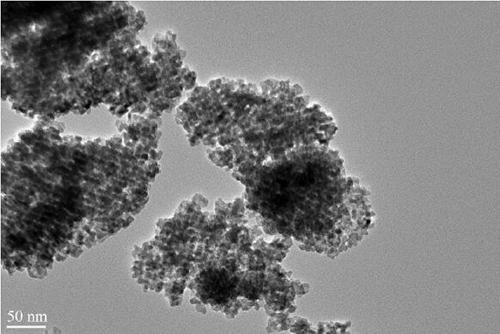

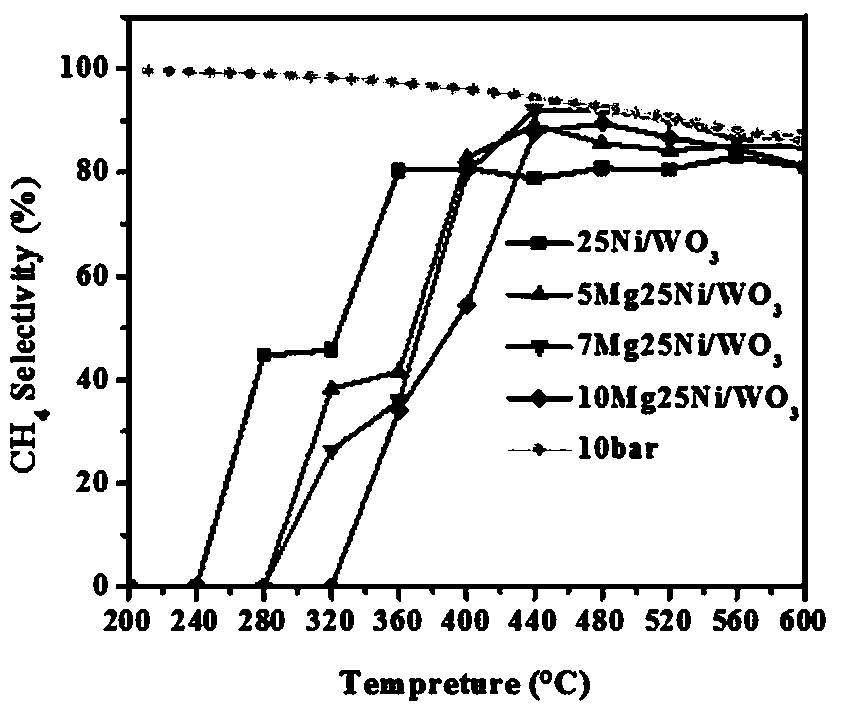

Image

Examples

Embodiment

[0024] The chemical substance materials used in this embodiment are: P123, concentrated hydrochloric acid, n-butanol, tetraethyl orthosilicate (TEOS), ammonium metatungstate, magnesium nitrate, nickel nitrate, hydrofluoric acid (HF), deionized water, Ethanol, nitrogen, argon, carbon monoxide, hydrogen, the combined amounts are as follows: in grams, milliliters, centimeters 3 is the unit of measurement.

[0025]

[0026] Selection of the above-mentioned chemical substances and materials: The chemical substances and materials required for the preparation should be selected and controlled for quality and purity:

[0027]

[0028] An ordered mesoporous MgNi / WO 3 The preparation method of methanation catalyst comprises the following steps:

[0029] (1) Preparation of KIT-6

[0030] Weigh 20g±0.001g P123, 32ml±0.001mL concentrated hydrochloric acid, a certain amount of deionized water, mix and stir until completely dissolved, add 26g±0.001g n-butanol, stir for 2h, add TEOS,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com