Bismuth ferrite-lead titanate-barium stannate titanate ternary system high-temperature piezoelectric ceramic material and preparation method thereof

A ceramic material, high-temperature piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of low piezoelectric coefficient, reduce lattice distortion, reduce leakage The effect of guiding and reducing unit cell parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the material is a traditional solid-phase synthesis process, including ball milling mixing, pre-sintering synthesis, secondary ball milling, granulation and tabletting, sintering, silver brushing and polarization. The ceramic material provided by the invention has the advantages of easy sintering, excellent piezoelectric performance, high Curie temperature, etc., and is very suitable for application in the field of high-temperature piezoelectric ceramic devices.

[0034] The preparation method of the bismuth ferrite-based high-temperature piezoelectric ceramic material in one embodiment of the present invention is shown below.

[0035] Step a), according to (1-x-y)BiFeO 3 -xPbTiO 3 -yBa(Sn 1 / 5 Ti 4 / 5 )O 3 +zMnCO 3 General formula, with high purity Bi 2 o 3 , Fe 2 o 3 , Pb 3 o 4 、TiO 2 、BaCO 3 , SnO 2 and MnCO 3 For the raw material powder, the raw material is wet ball milled, mixed evenly and dried. For example, each raw materia...

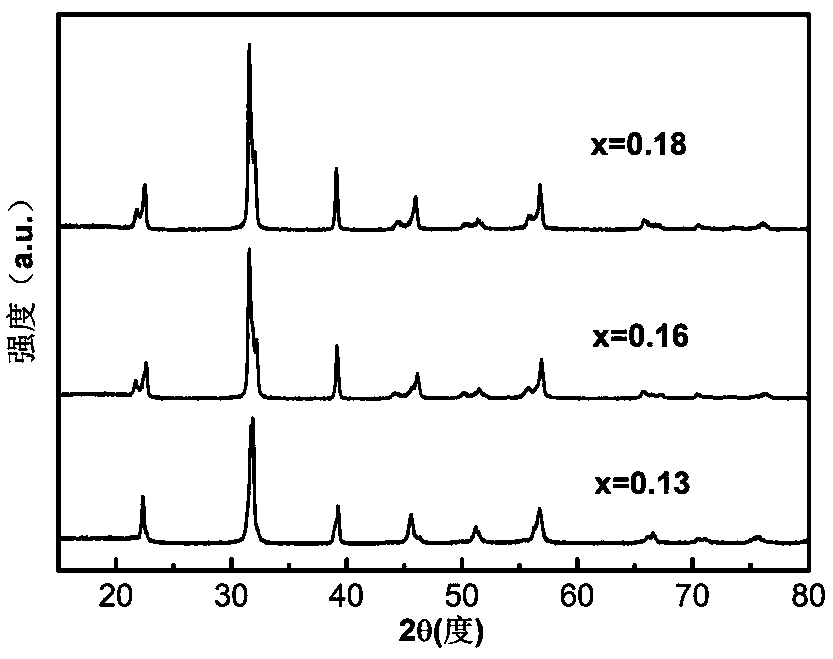

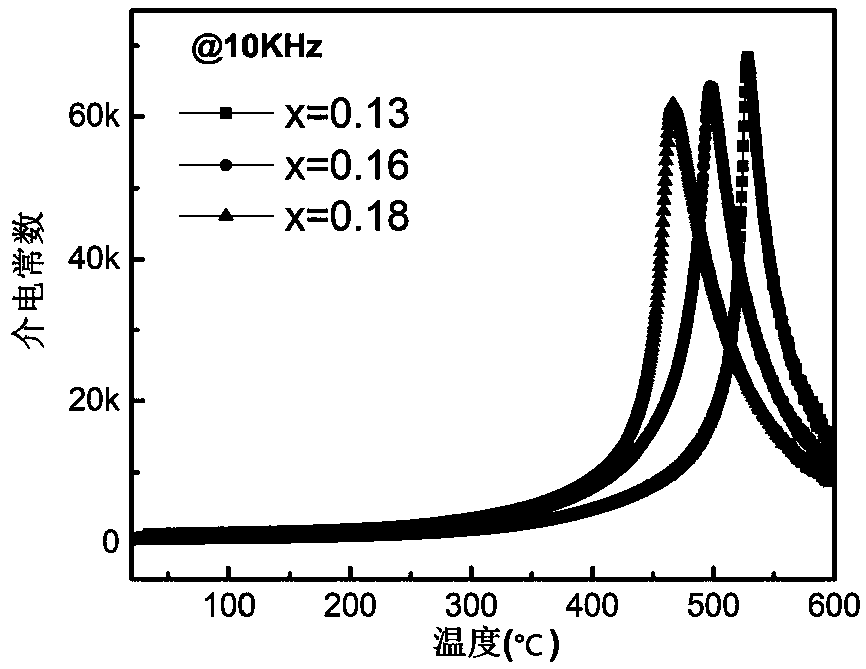

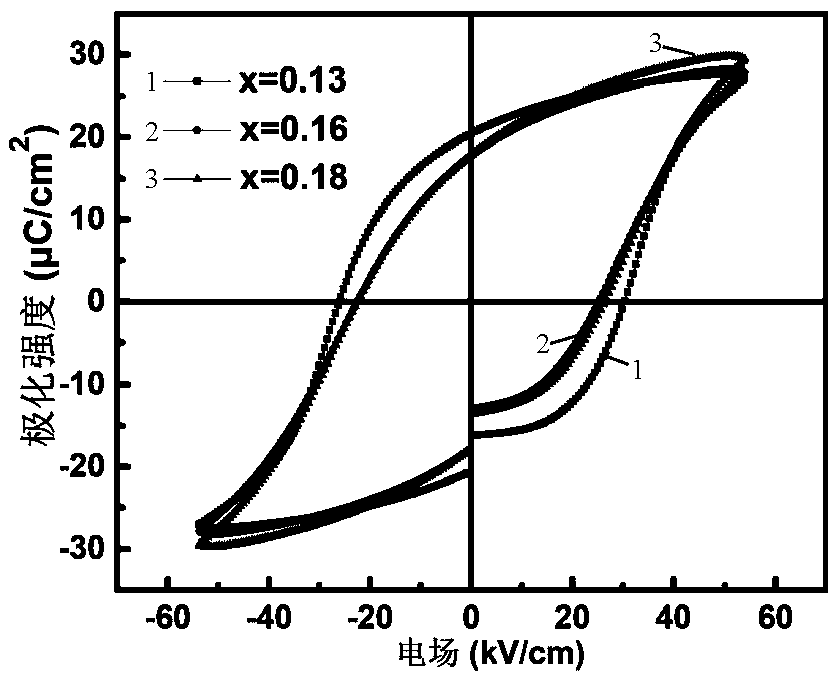

Embodiment 1

[0044] The composition of a bismuth ferrite-based ternary high-temperature piezoelectric ceramic material is selected as: 0.63BiFeO 3 -0.24PbTiO 3 -0.13Ba(Sn 1 / 5 Ti 4 / 5 )O 3 +0.15%wtMnCO 3 .

[0045] The preparation method of the above-mentioned high-temperature piezoelectric ceramic material comprises the following steps:

[0046] a) with high purity Bi 2 o 3 , Fe 2 o 3 , Pb 3 o 4 、TiO 2 、BaCO 3 , SnO 2 and MnCO 3 For raw material powder, according to 0.63BiFeO 3 -0.24PbTiO 3 -0.13Ba(Sn 1 / 5 Ti 4 / 5 )O 3 +0.15%wtMnCO 3 The general formula accurately weighs a total of 50g, put the raw materials into a ball mill tank, use absolute ethanol as the ball mill medium, mix and ball mill on a planetary ball mill for 6 hours, and put the material out into a 100°C oven for rapid drying;

[0047] b) After the uniformly mixed powder is sieved and compacted, the temperature is raised to 800-820°C at a heating rate of 5°C / min, and calcined at 800-820°C for 4-6 hours to ob...

Embodiment 2

[0059] In this embodiment, the composition of a bismuth ferrite-based ternary high-temperature piezoelectric ceramic material is selected as: 0.60BiFeO 3 -0.24PbTiO 3 -0.16Ba(Sn 1 / 5 Ti 4 / 5 )O 3 +0.12%wtMnCO 3 .

[0060] The preparation method of the above-mentioned high-temperature piezoelectric ceramic material comprises the following steps:

[0061] a) with high purity Bi 2 o 3 , Fe 2 o 3 , Pb 3 o 4 、TiO 2 、BaCO 3 , SnO 2 and MnCO 3For raw material powder, according to 0.60BiFeO 3 -0.24PbTiO 3 -0.16Ba(Sn 1 / 5 Ti 4 / 5 )O 3 +0.12%wtMnCO 3 The general formula accurately weighs a total of 50g, put the raw materials into a ball mill tank, use absolute ethanol as the ball mill medium, mix and ball mill on a planetary ball mill for 6 hours, and put the material out into a 100°C oven for rapid drying;

[0062] b) After sieving and briquetting the uniformly mixed powder, raise the temperature to 800-820°C at a heating rate of 5°C / min, and calcinate at 800-820°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercive field | aaaaa | aaaaa |

| Coercive field | aaaaa | aaaaa |

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com