Method and device for treating residual ammonia water and applying ammonia distillation wastewater to coke quenching

A technology for distilling ammonia wastewater and ammonia water, which is applied in coke cooling, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of consuming large water resources, affecting treatment, containing a large amount of ammonia, etc., and achieve the goal of reducing corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

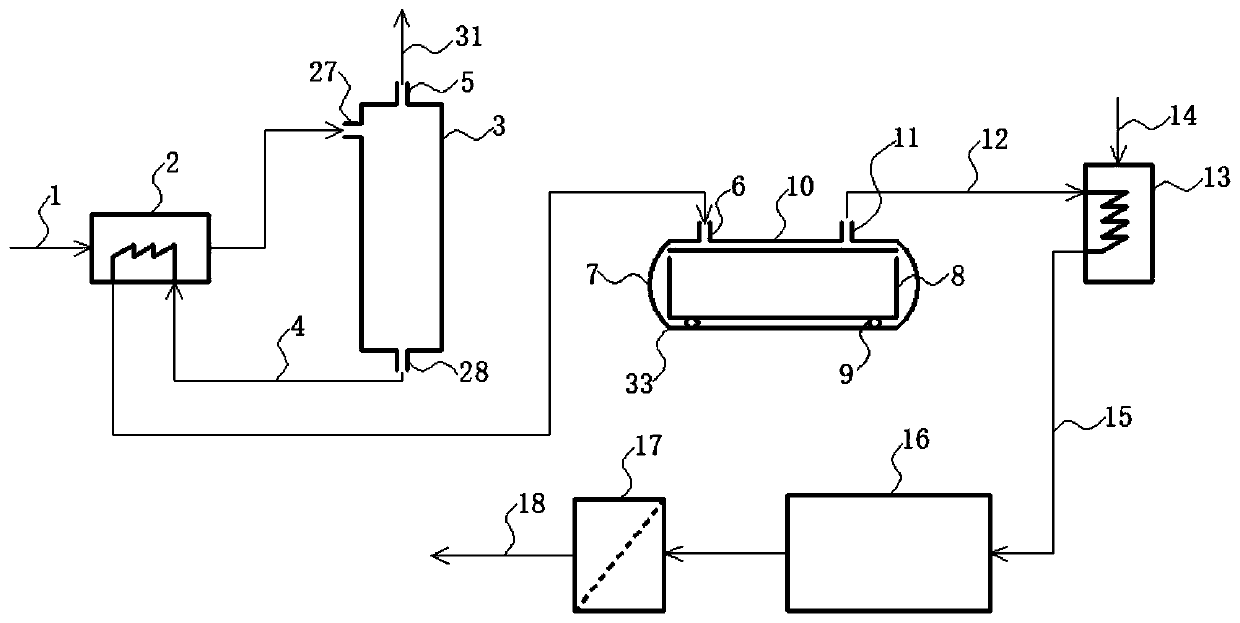

Embodiment 1

[0036] This embodiment is an embodiment of removing ammonia from residual ammonia water in the coking industry and using ammonia distillation wastewater to quench coke. The process flow is as follows figure 1 shown. The remaining ammonia water 1 is heated to 80°C by the heat source in the preheater 2, and then enters the ammonia distillation tower 3 through the residual ammonia water inlet 27 of the ammonia distillation tower to separate the ammonia and volatile organic compounds contained in the liquid phase from the liquid phase, so that The ammonia concentration in the effluent is reduced to below 800 mg / l, and the ammonia distillation tower 3 can have a rectification section and a stripping section at the same time, or only have a stripping section. The heat source heats the liquid phase at the bottom of the distillation tower (not shown in the figure), and the heat source for heating the liquid phase can be steam or heat transfer oil. The ammonia distillation wastewater ...

Embodiment 2

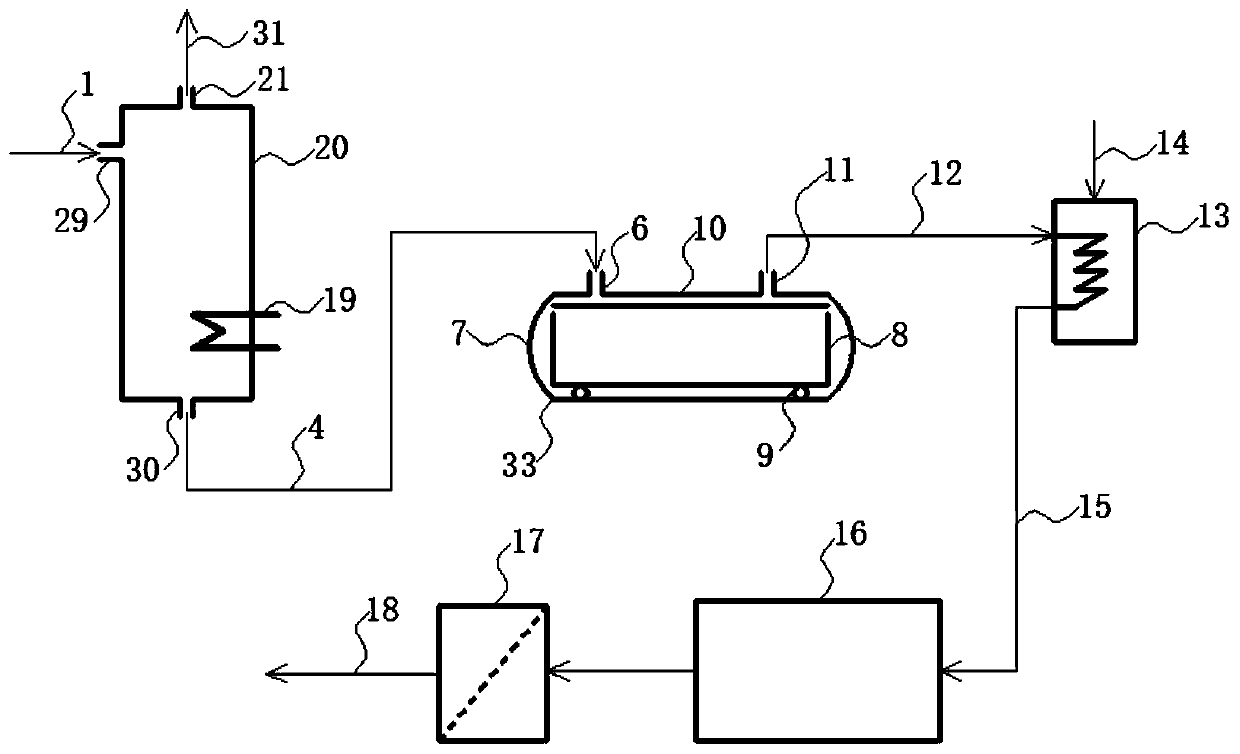

[0041] This embodiment is basically the same as Embodiment 1, except that the evaporator 20 is used to replace the preheater 2 and the ammonia distillation tower 3, and the remaining ammonia water with a small amount of water is used as the treatment object, and the evaporator 20 does not contain stripping Section and rectification section of the heated evaporation tank. like figure 2 As shown, the remaining ammonia water enters the evaporator through the remaining ammonia water inlet 29 of the evaporator, and at the same time, the heat source enters directly from the heat source inlet 19 of the evaporator, and heats the remaining ammonia water in the evaporator to raise the temperature of the remaining ammonia water to between 80°C and 130°C. any temperature in between. Under the action of high temperature, the ammonia and volatile organic compounds contained in the liquid phase are separated from the liquid phase, the concentration of ammonia in the effluent is reduced to ...

Embodiment 3

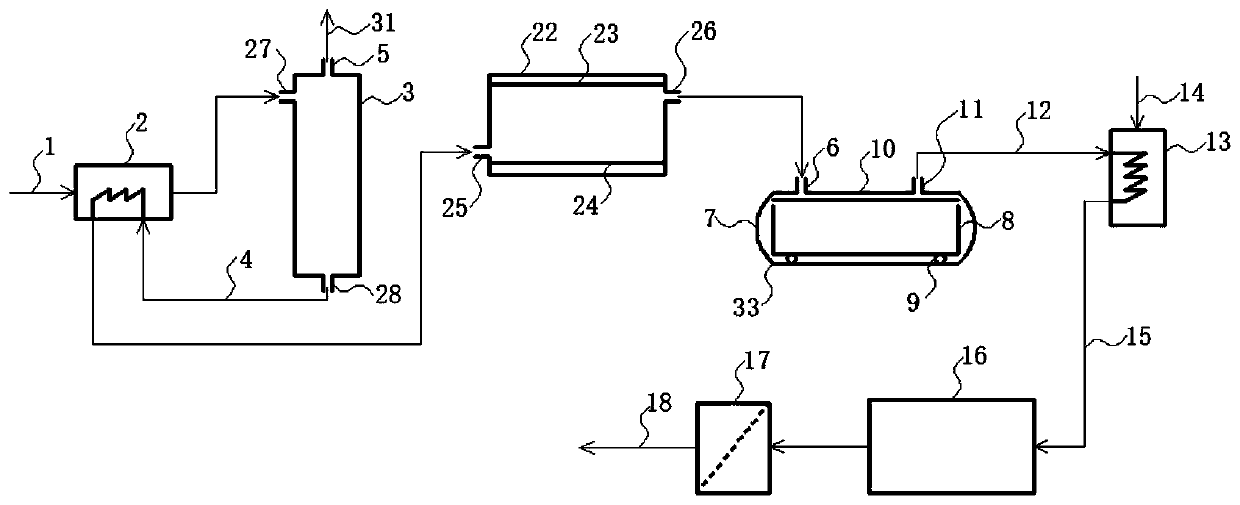

[0044] This embodiment is basically the same as Embodiment 1, except that the ammonia distillation waste water 4 after preliminary ammonia removal by the ammonia distillation tower 3 and heat exchange with the remaining ammonia water is not directly used for coke quenching, but first enters the electrochemical equipment 22 Electrochemical treatment is carried out inside. like Figure 4As shown, the ammonia distillation wastewater enters through the wastewater inlet 25 of the electrochemical equipment and flows through the space between the anode plate 23 and the cathode plate 24, and the wastewater is treated under the action of a DC electric field to remove the easily oxidizable substances in the wastewater. degrades and raises the pH to around 10.2. The treated wastewater flows out through the wastewater outlet 26 of the electrochemical equipment, and enters the closed coke quenching tank 10 to complete the coke quenching and vaporization and ammonia removal process, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap