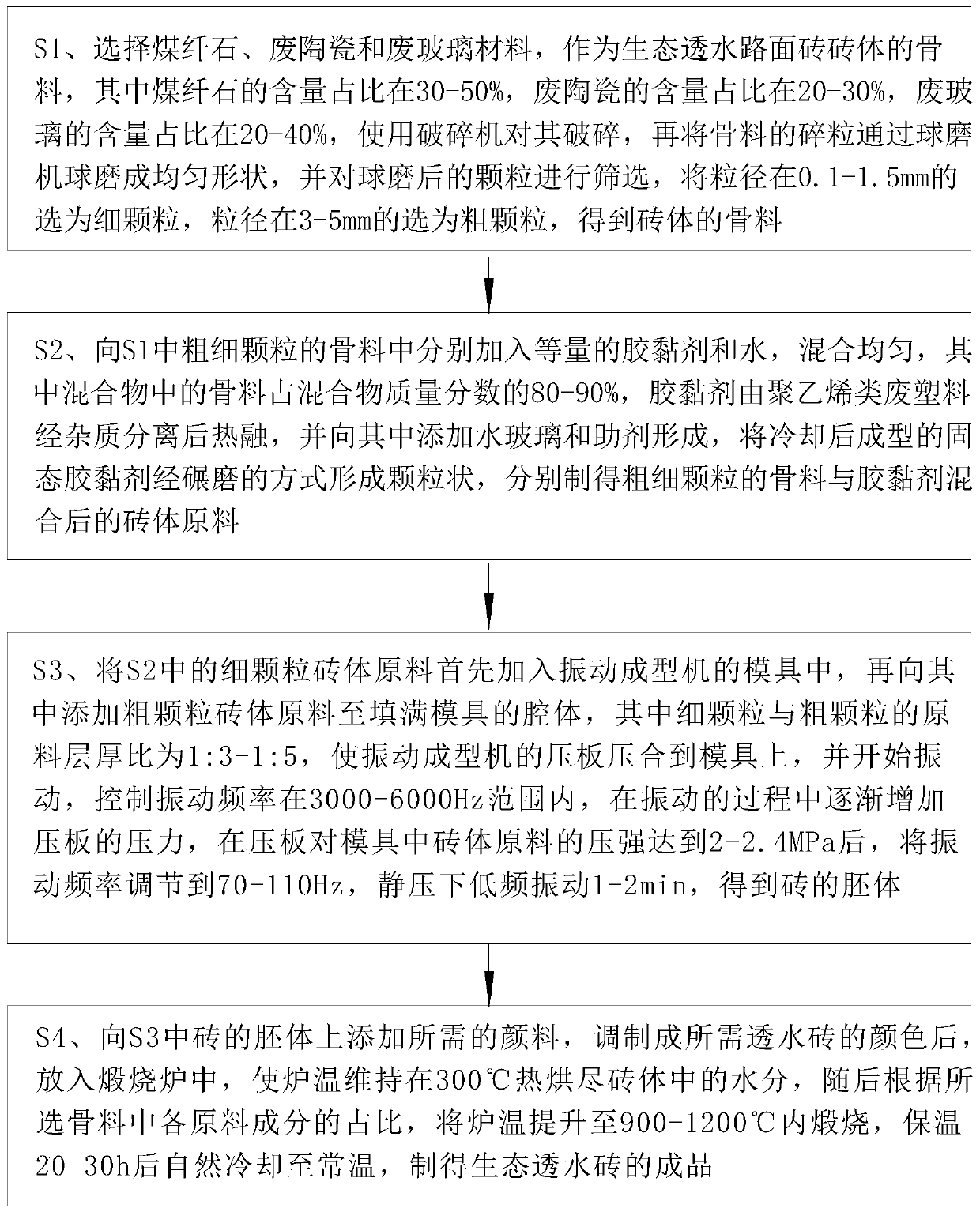

Ecological permeable pavement brick and production process thereof

A permeable pavement brick and ecological technology, applied in the field of building blocks, can solve the problems that cannot be effectively evaporated, and the water storage characteristics of ecological permeable pavement bricks cannot be effectively realized, and achieve the effect of weakening the heat island effect and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

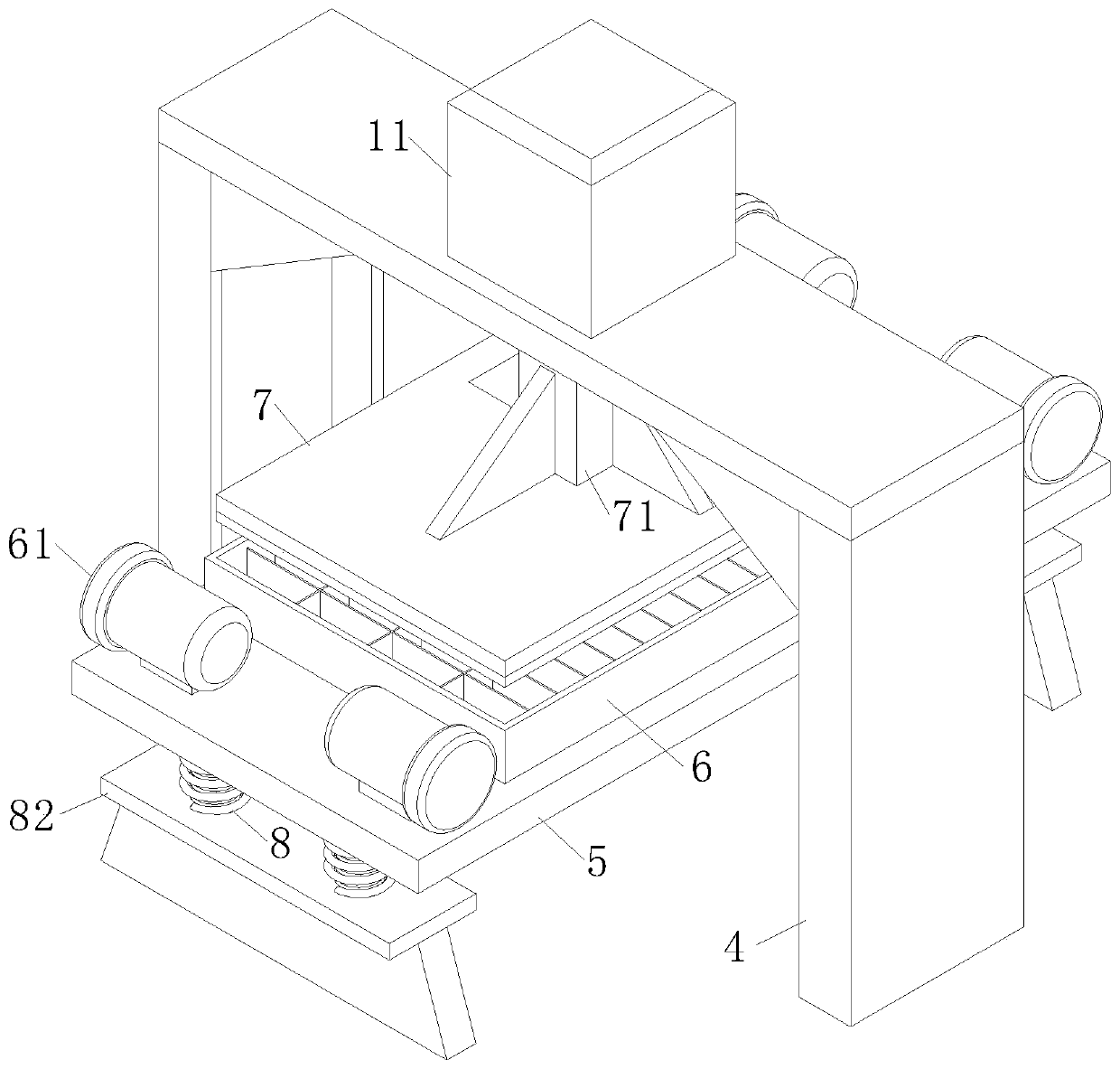

Embodiment approach

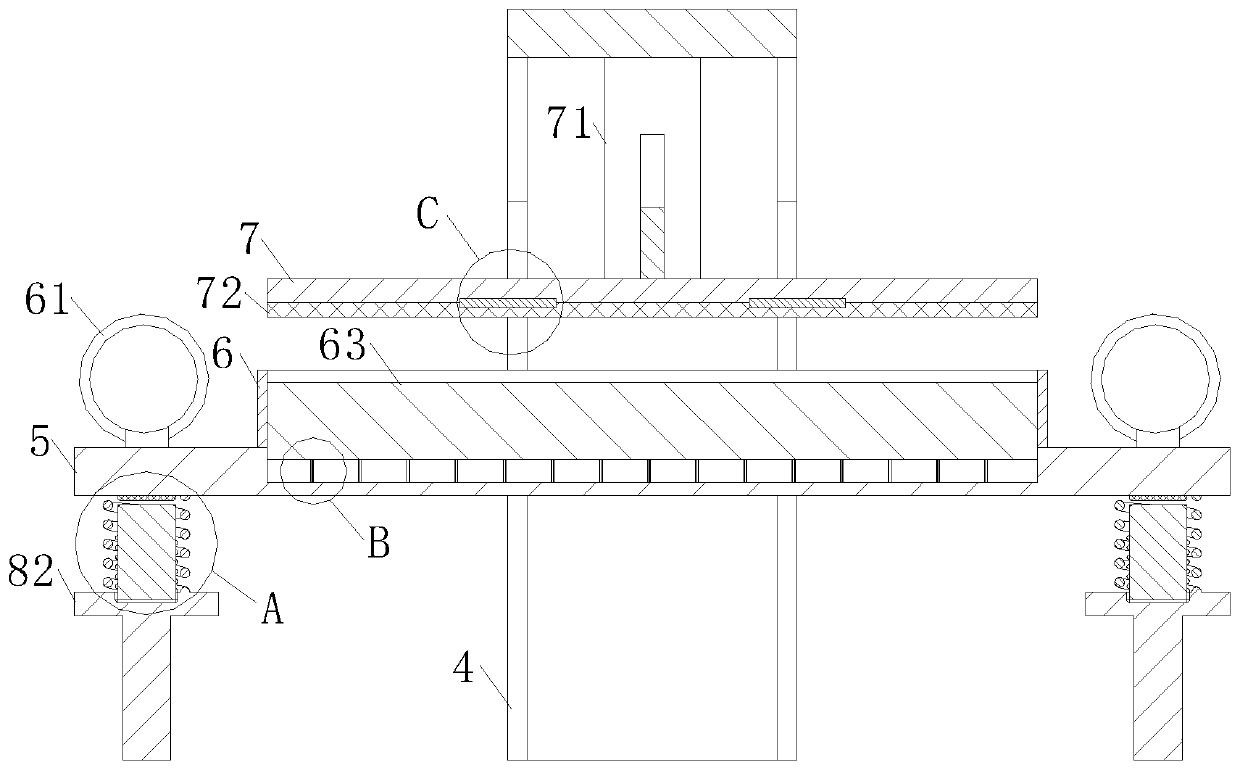

[0035]As an embodiment of the present invention, a corrugated plate 72 is provided below the pressing plate 7, and several magnetic block protrusions 73 are arranged on the lower surface of the pressing plate 7; Corresponding several magnetic notches 721; when processing the pattern on the surface of the brick body, the required brick body pattern is obtained by cutting and grinding the surface of the prepared brick body, which increases the workload of the brick body processing process, and at the same time The components removed by cutting and grinding cause a waste of brick body materials; screws are used to fix the pattern plate 72 on the pressure plate, and the screws make the fixed position of the pattern plate 72 unique, and the distance between the pattern plate 72 after extrusion and the position of the mold 6 cannot be adjusted. Offset, wear after long-term use, and the repair of screw holes and screws are relatively cumbersome; through the pattern plate 72 arranged u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com