Fermented feed and preparation method and application thereof, and layer feed

A technology for fermented feed and laying hen feed, applied in the field of fermented feed preparation and laying hen feed, can solve the problem that the market value is not best reflected, maximize product benefits, promote growth performance and production performance, improve Effects of Feathers and Health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

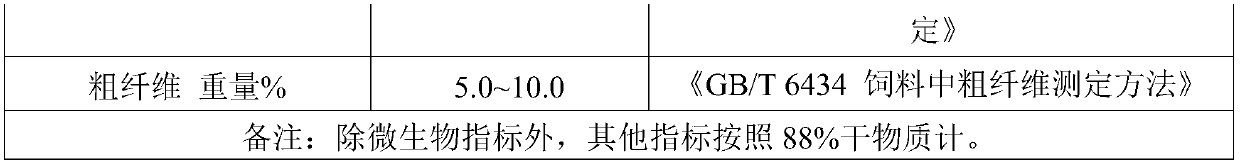

Image

Examples

preparation example Construction

[0018] In the first aspect, the present invention provides a method for preparing fermented feed, the method comprising: mixing cornstarch residue, corn flour, DDGS, DDS, sprayed corn bran and molasses to obtain a fermentation substrate, and then fermenting bacteria Seeds are inoculated into the fermentation substrate, and fermented to obtain the fermented feed.

[0019] Although cornstarch residue, corn flour, DDGS, DDS, sprayed corn bran and molasses are used as the fermentation substrate to achieve the purpose of the present invention, that is, to promote the consumption of feed products containing the fermented feed prepared by this method growth performance and production performance of animals, but the inventors of the present invention further found in research that when relative to 100 parts by weight of cornstarch residue, the amount of corn flour is 10-80 parts by weight, and the sprayed corn bran The consumption of 200-1000 parts by weight, the consumption of DDS is...

Embodiment 1-5

[0067] Embodiment 1-5 is used to illustrate fermented feed provided by the present invention and preparation method thereof

[0068] The raw materials are mixed evenly according to the ratio in Table 3 to obtain the fermentation substrate, and the pH value of the fermentation substrate is adjusted to the level in Table 3 by using light calcium carbonate (purchased from Lingshou County Dezhou Mineral Products Processing Factory), and then Inoculate Lactobacillus acidophilus, Candida utilis, Bacillus subtilis and Bacillus licheniformis according to the inoculation ratio of each bacterial strain in Table 3, mix evenly, put into the inner membrane bag (the material accounts for two-thirds volume of the inner membrane bag, The air in the inner membrane bag is not emptied during welding), and fermented at 35±2°C for 30 hours to obtain fermented feed A1-A5.

[0069] table 3

[0070]

Embodiment 6

[0072] This embodiment is used to illustrate the fermented feed provided by the present invention and its preparation method

[0073] The fermented feed was prepared according to the method of Example 1, except that ammonia water was used to adjust the pH value of the fermentation substrate to obtain fermented feed A6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com