Method for preparing coal water slurry by mixing coal and semicoke as raw materials with wastewater

A technology for mixing wastewater and coal-water slurry, applied in the field of clean coal, can solve the problems of failure to achieve zero discharge of wastewater, unusable coal powder, and high processing costs, maximize product benefits, have good fluidity, and improve coal-water slurry. effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

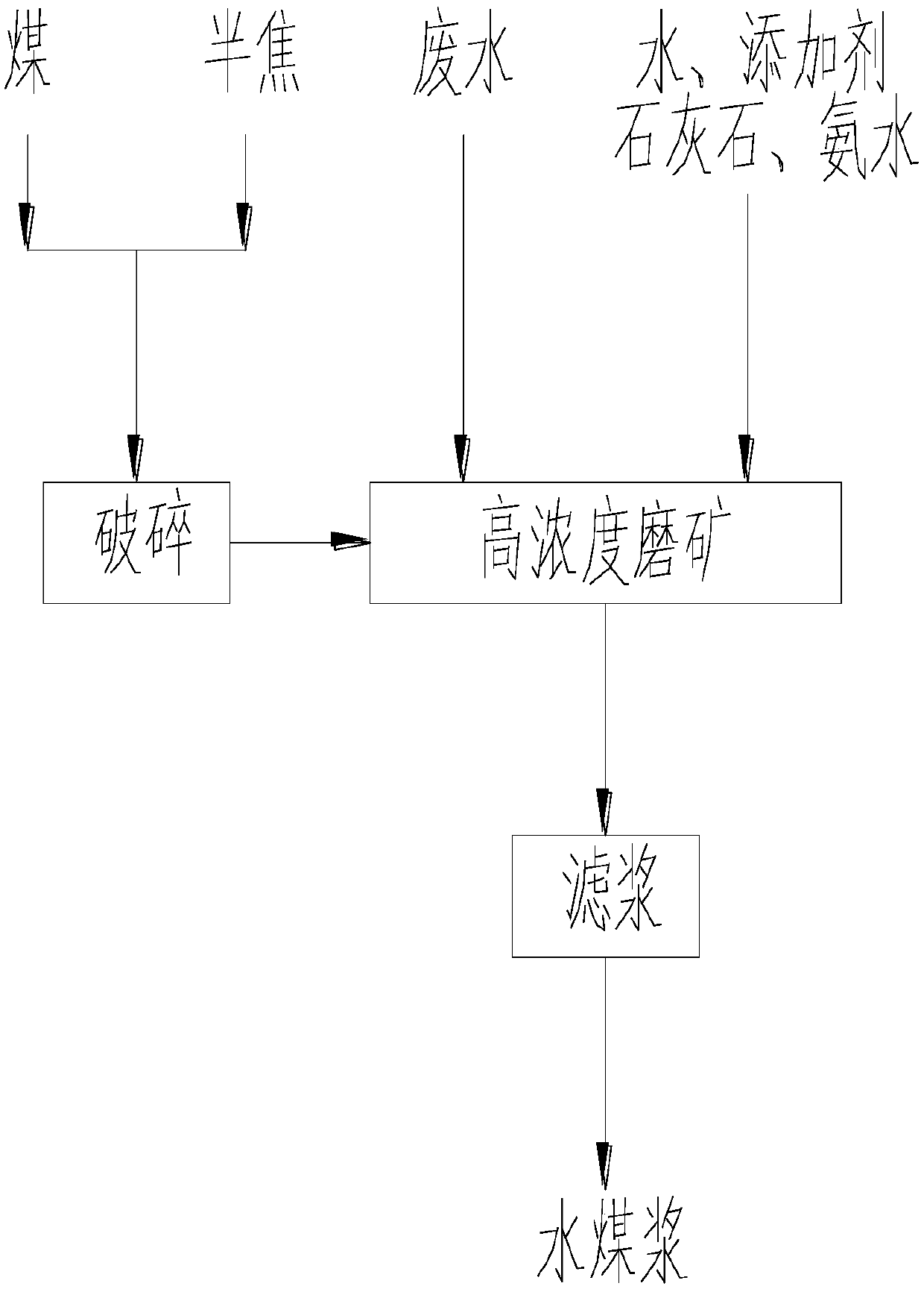

[0027] This implementation case is used to illustrate a method for preparing coal-water slurry from waste water mixed with coal and semi-coke as raw materials.

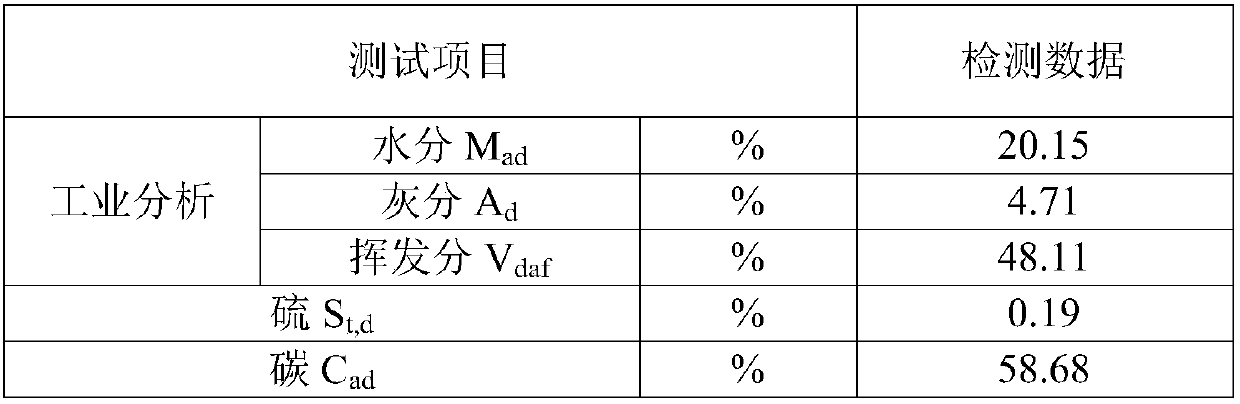

[0028] The coal used in this example is lignite below 6mm in the Naomao Lake area of Xinjiang, and the semi-coke used is the semi-coke below 6mm obtained by pyrolyzing this lignite at 350°C for 2 hours. Raw material analysis indicators are as follows:

[0029] Table-1 lignite analysis indicators

[0030]

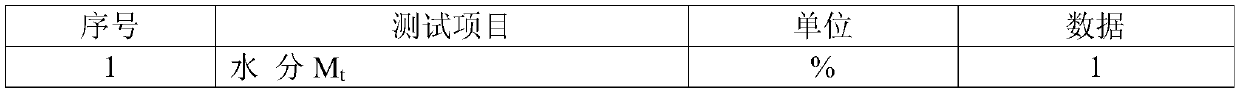

[0031] Table-2 semi-focus analysis indicators

[0032]

[0033]

[0034] The lignite and semi-coke are blended at a mass ratio of 12:52 (0.23:1). After the blend is added to the crusher for crushing, the waste water produced in the gas purification process is added to the coal mill at a mass ratio of 64:1, and the wet high-concentration grinding and pulping process is used for pulping.

[0035] The wastewater analysis indicators are shown in the table below:

[0036] Table-3 Wastewater analysis indica...

Embodiment 2

[0044] The coal used in this example is the long-flame coal in northern Shaanxi, and the semi-coke used is the semi-coke obtained by pyrolyzing the long-flame coal at 650°C for 1 hour. Raw material analysis indicators are as follows:

[0045] Table-5 Analysis indicators of long-flame coal

[0046]

[0047] Table-6 semi-focus analysis indicators

[0048] serial number

Test items

unit

data

1

Moisture M t

%

2

2

Ash A d

%

6.25

3

Volatile V d

%

12

4

Cartridge calorific value (Qb, ad)

MJ / kg

29

5

Sulfur S t,d

%

0.21

6

fixed carbon FC ad

%

85

[0049] The long-flame coal and semi-coke are blended at a mass ratio of 31:31 (1:1). After the mixture is put into the crusher for crushing, the waste water produced in the gas purification process is added to the coal mill at a mass ratio of 62:1, and the wet high-concentration grinding pulping process is us...

Embodiment 3

[0057] The coal used in this example is lignite from the Xiaolongtan area, and the semi-coke used is the semi-coke obtained by pyrolyzing this long-flame coal at 500°C for 1 hour and 30 minutes. Raw material analysis indicators are as follows:

[0058] Table-9 Lignite Analysis Indicators

[0059]

[0060]

[0061] Table-10 semi-focus analysis indicators

[0062] serial number

Test items

unit

data

1

Moisture M t

%

1.54

2

Ash A d

%

13.67

3

Volatile V d

%

13

4

Cartridge calorific value (Qb, ad)

MJ / kg

24.7

5

Sulfur S t,d

%

1.36

6

fixed carbon FC ad

%

75.68

[0063] The lignite and semi-coke are blended at a mass ratio of 45:9 (5:1). After the mixture is put into the crusher for crushing, the waste water produced in the gas purification process is added to the coal mill at a mass ratio of 70:1, and the wet high-concentration grinding pulping pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com