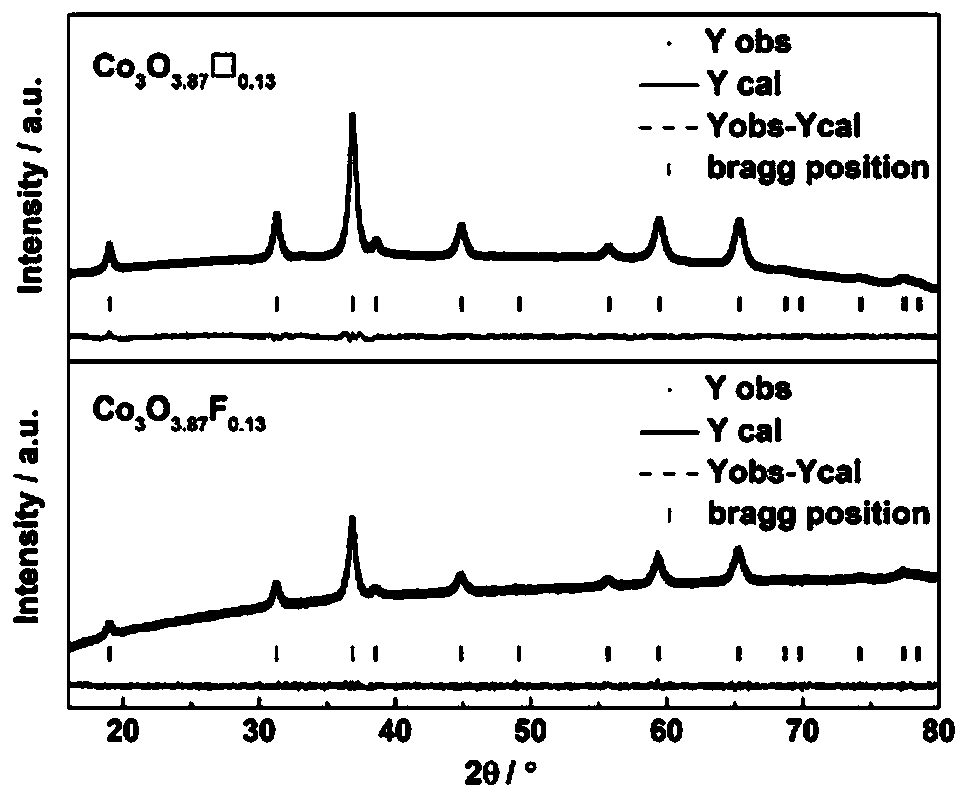

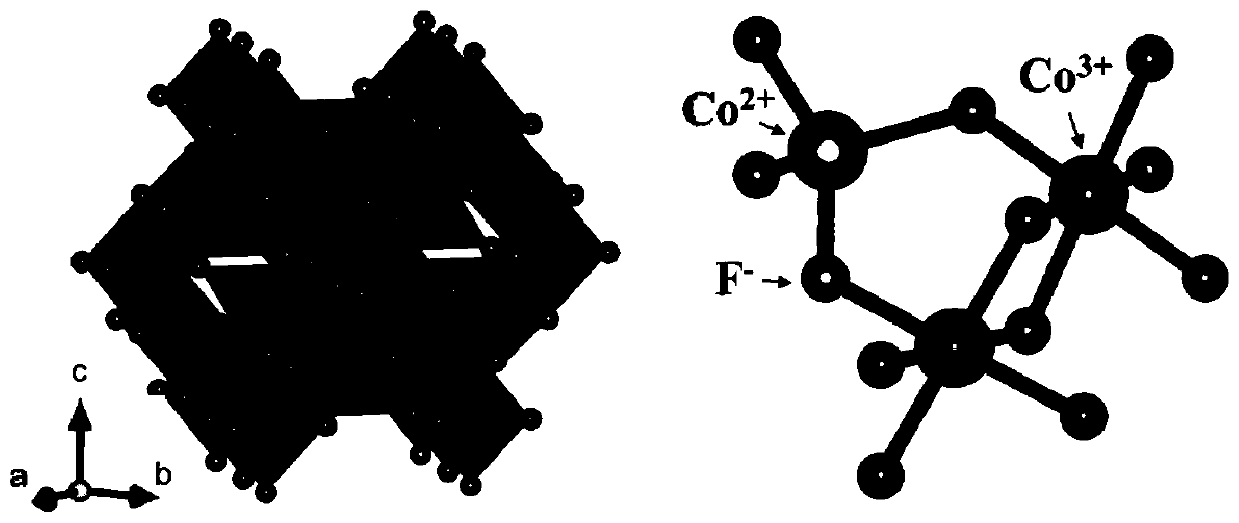

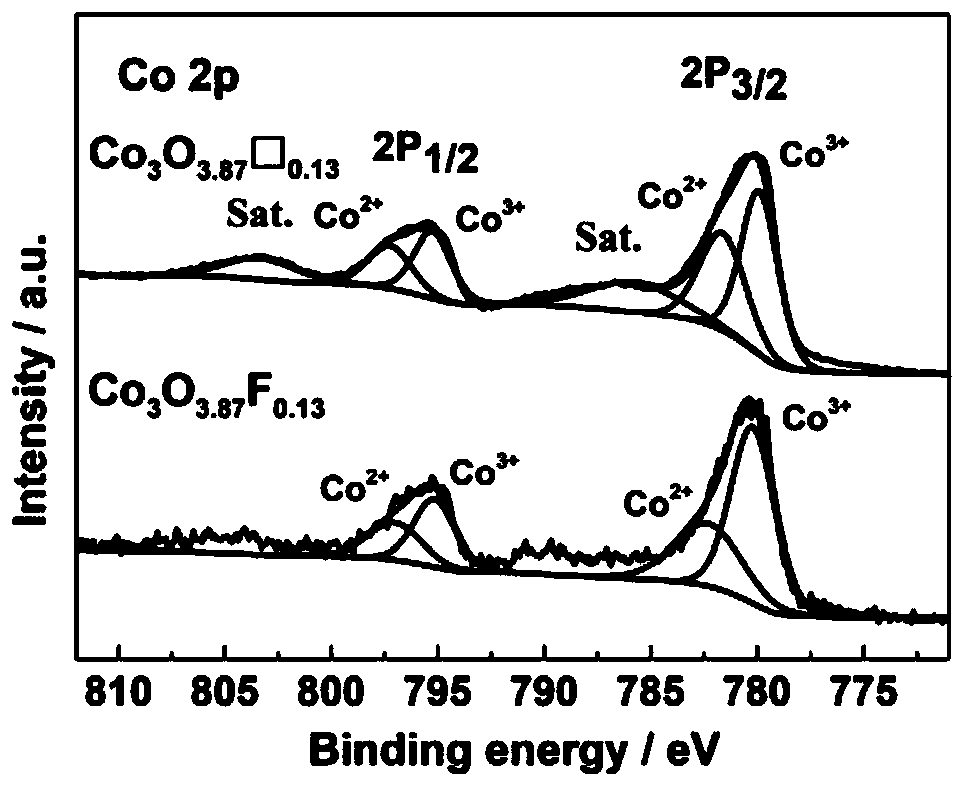

Fluorine-doped spinel structure cobaltosic oxide electro-catalytic material and preparation method thereof

A technology of cobalt tetraoxide electricity and spinel structure, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of slow reaction kinetics, high cost and scarcity In order to achieve the effects of mild reaction conditions, high OER electrocatalytic activity, and increase the electrochemical active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A fluorine-doped spinel structure cobalt tetroxide electrocatalytic material, the preparation method of which is as follows:

[0037] Step 1, 10g amphiphilic triblock polymer P123 (EO 20 –PO 70 –EO 20 , molecular weight=5800, Aldrich (Aldrich)) was added to the mixed solution of 50mL concentrated HCI (37wt%) and 325mL deionized water, stirred and dissolved in a 38°C oil bath until the solution turned white, and then added 20.8g Tetraethyl orthosilicate (TEOS) continued magnetic stirring for 24 hours to obtain a milky white mixed solution; then poured the milky white mixed solution into the lining of a 50mL high-pressure reactor, and performed a solvothermal reaction at 100°C for 24 hours; the solvothermal reaction product was filtered with water and ethanol The white sample was obtained by washing 3 times; finally, the white sample was calcined in a muffle furnace at 550 °C for 5 h with a heating rate of 2 °C min -1 , get SBA-15;

[0038] Step 2, 1.1642g cobalt nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com