Nickel carbide material, nickel carbide cathode capable of enhancing electricity generation and preparation method and application of nickel carbide cathode

A nickel carbide, cathode technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve problems such as poor catalytic effect, achieve aerobic reduction performance, low charge transfer internal resistance, and reduce the effect of charge transfer internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

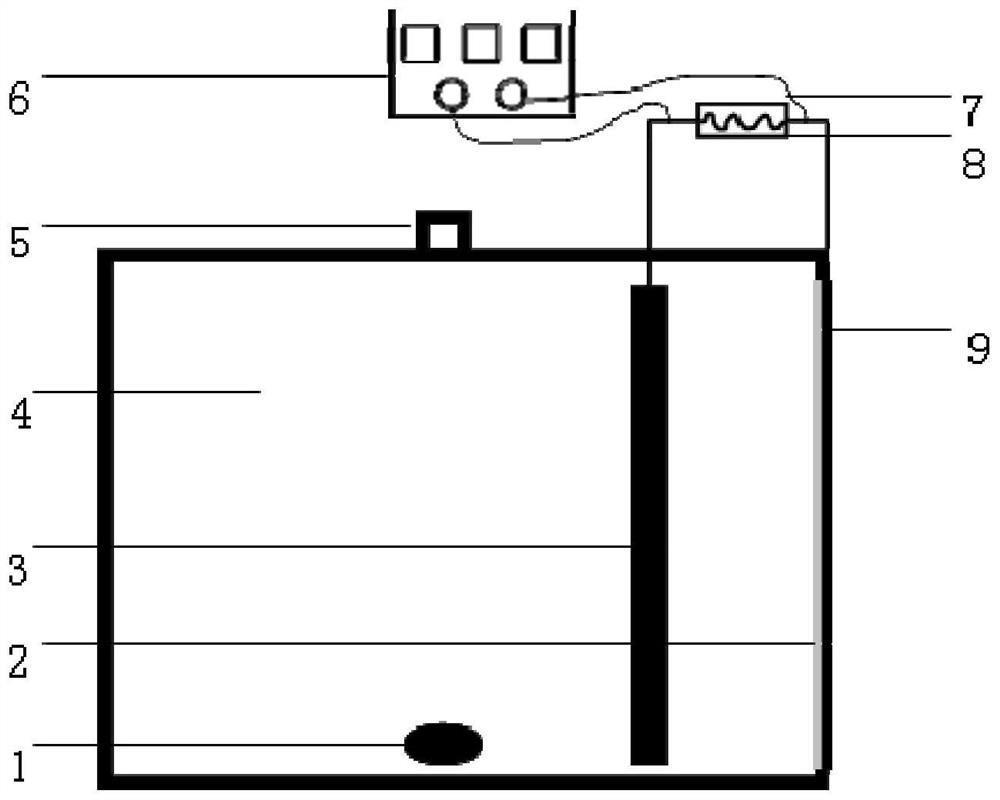

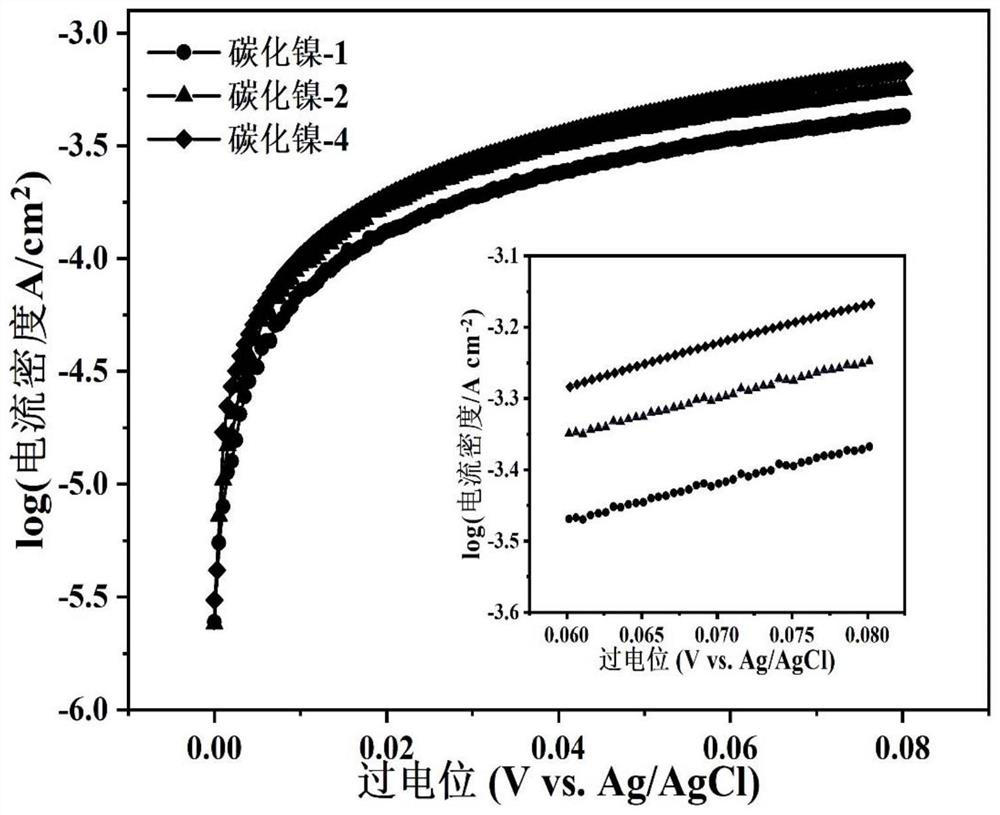

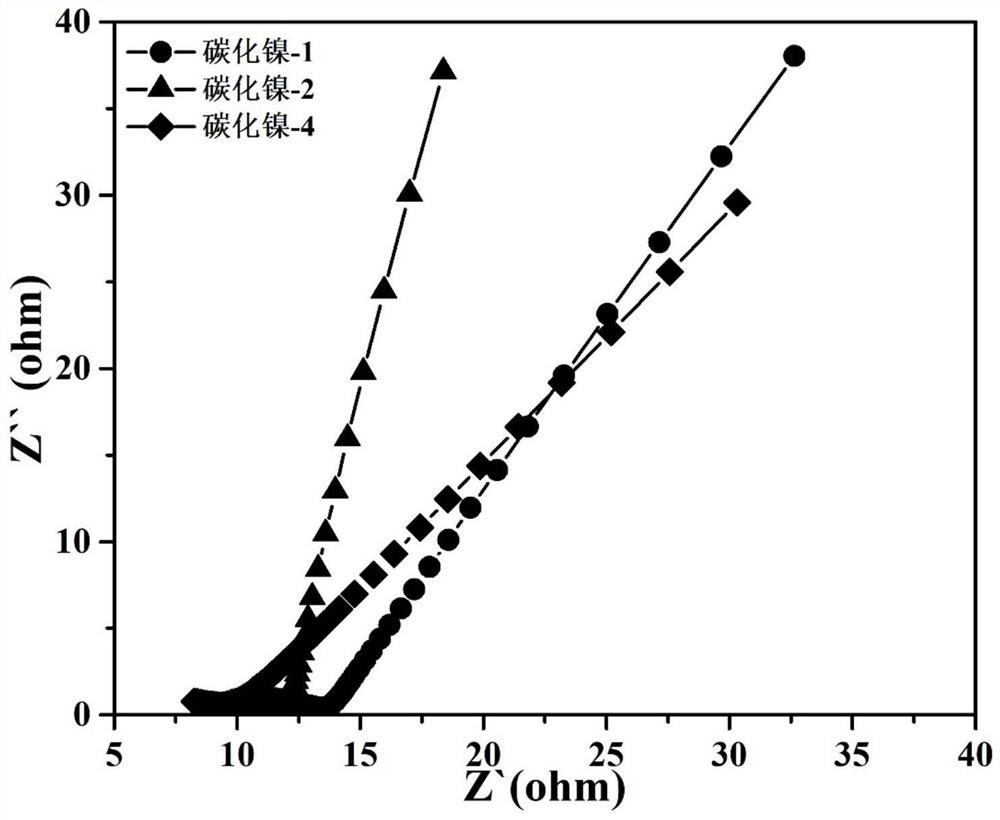

[0084] This embodiment provides a nickel carbide material, which is used as a catalytic material to prepare a nickel carbide cathode (nickel carbide-2), and the specific process is as follows.

[0085] (1) Preparation of nickel carbide material:

[0086] Mix the melamine solution containing 0.021mol / L, the formaldehyde solution of 0.012mol / L and the nickel acetate solution of 0.012mol / L in a volume ratio of 2:1:1, and form a uniform pink solution by stirring for 20min; the mixed solution After heating in a polytetrafluoroethylene reactor at 170°C for 16h, wash with absolute ethanol and ultrapure water three times to remove impurities, and then dry the sample in a 60°C drying oven for 25h; then the dried The sample was placed in a vacuum tube furnace at 800 °C for further heating for 2.2 h under the protection of nitrogen to obtain a nickel carbide material.

[0087] (2) Preparation of nickel carbide catalyst layer:

[0088] Mix ultrapure water, Nafion solution, and pure isop...

Embodiment 2

[0092] This embodiment provides a nickel carbide material, which is used as a catalytic material to prepare a nickel carbide cathode (nickel carbide-4). The specific process is as follows.

[0093] (1) Preparation of nickel carbide material:

[0094] Mix the melamine solution containing 0.025mol / L, the formaldehyde solution of 0.010mol / L and the nickel acetate solution of 0.008mol / L in a volume ratio of 1:1:0.9, and form a uniform pink solution by stirring for 10 minutes; the mixed solution After heating in a polytetrafluoroethylene reactor at 180°C for 18h, wash with absolute ethanol and ultrapure water three times to remove impurities, and then place the sample in a drying oven at 55°C for 20h; then dry the dried The sample was placed in a vacuum tube furnace at 1000°C and further heated for 2.0 h under nitrogen protection to obtain the desired sample.

[0095] (2) Preparation of nickel carbide catalyst layer:

[0096] Mix ultrapure water, Nafion solution, and pure isoprop...

Embodiment 3

[0100] This embodiment provides a nickel carbide material, which is used as a catalytic material to prepare a nickel carbide cathode (nickel carbide-1). The specific process is as follows.

[0101] (1) Preparation of nickel carbide material:

[0102] Mix the melamine solution containing 0.015mol / L, the formaldehyde solution of 0.015mol / L and the nickel acetate solution of 0.0135mol / L in a volume ratio of 1.5:1:0.8, and form a uniform pink solution by stirring for 15 minutes; the mixed solution After heating in a polytetrafluoroethylene reactor at 150°C for 20h, wash with absolute ethanol and ultrapure water three times to remove impurities, and then place the sample in a drying oven at 65°C for 30h; then dry the dried The sample was placed in a vacuum tube furnace at 900°C for further heating for 1.8 h under nitrogen protection to obtain the desired sample.

[0103] (2) Preparation of nickel carbide catalyst layer:

[0104] Mix ultrapure water, Nafion solution, and pure isop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com