Anaerobic treatment process for organic wastewater

An organic wastewater and anaerobic treatment technology, which is applied in the field of sewage purification, can solve the problems of complex internal structure, the influence of SS on the influent of anaerobic process, and the added price, and achieve strong impact load resistance, solve wastewater treatment problems, The effect that is not easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

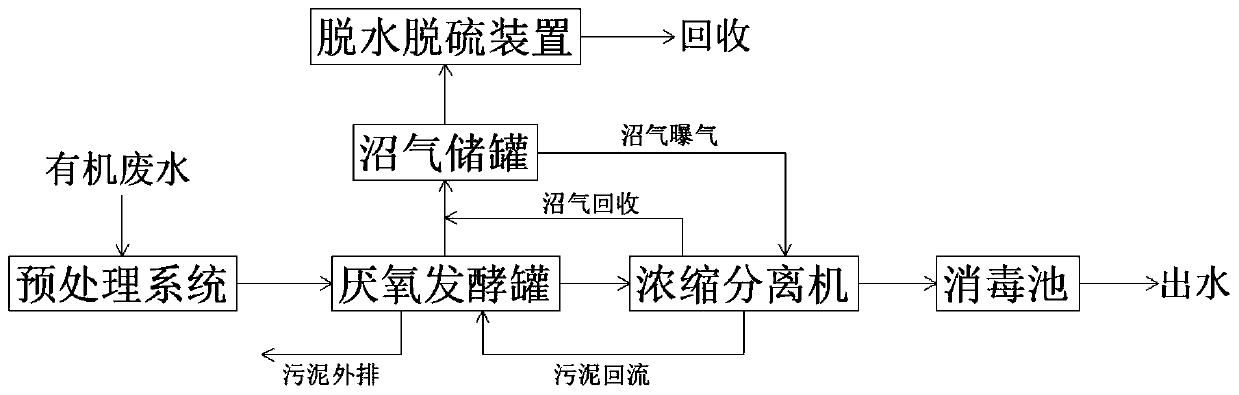

[0019] Such as figure 1 A kind of anaerobic treatment process of organic waste water shown, concrete embodiment is:

[0020] According to the water quality of organic wastewater generated from food processing, paper mills, farms, etc., the organic wastewater is discharged into the pretreatment system for treatment. The pretreatment system can use physical and chemical methods such as grid machine, solid-liquid separator or pH adjustment tank. Pretreatment is carried out to achieve the purpose of removing most large suspended particles or neutralizing water quality. After being treated by the pretreatment system, the sewage is pumped into the anaerobic fermentation tank. In order to balance the value-added of methanogenic bacteria and the speed of discharge, the sludge residence time in the anaerobic fermentation tank is 10-15 days, the ambient temperature is 30°C-45°C, and the concentration load is 3-4kgCOD / (m 3 d), remove COD, SS and other pollutants through anaerobic ferme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com