Anti-corrosion alcohol-based fuel for boiler

An alcohol-based fuel and anti-corrosion technology, applied in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of low harmful gas emissions, service life of oil leakage of equipment, and easy corrosion of equipment, achieving simple formula, Prevent delamination, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

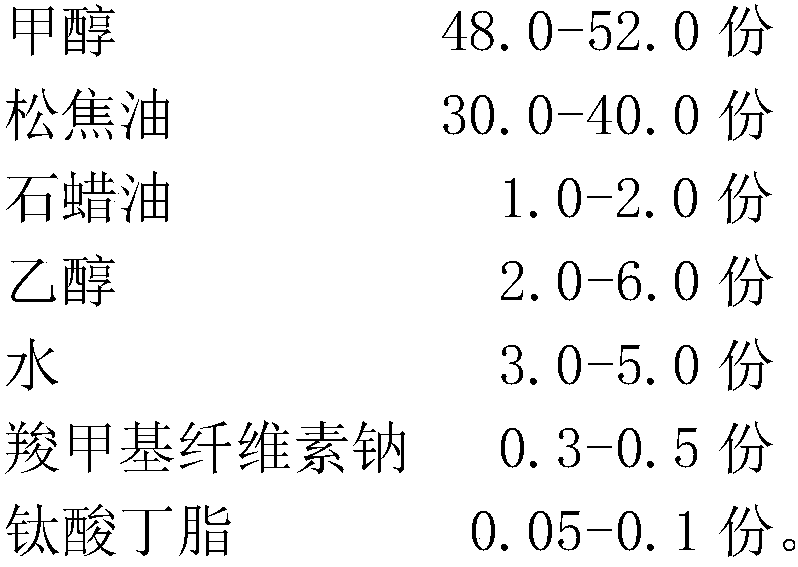

[0035] A corrosion-resistant boiler alcohol-based fuel consisting of the following ingredients by weight:

[0036]

[0037]

[0038]A method for preparing an anti-corrosion boiler alcohol-based fuel, comprising the following steps:

[0039] 1) Mix methanol and ethanol evenly, add pine tar and paraffin oil, stir, and mix evenly;

[0040] 2) Add butyl titanate to the material obtained in step 1), stir and mix evenly;

[0041] 3) At room temperature, slowly add sodium carboxymethylcellulose into water heated to 40-42°C, add while stirring, mix evenly, and dissolve completely;

[0042] 4) Add the material obtained in step 2) to the material obtained in step 3), stir and mix evenly to obtain the product.

Embodiment 2

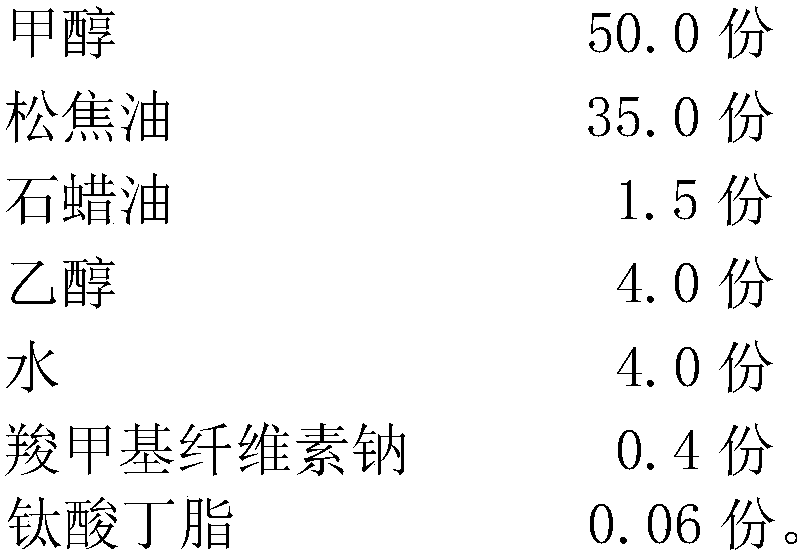

[0044] A corrosion-resistant boiler alcohol-based fuel consisting of the following ingredients by weight:

[0045]

[0046] A method for preparing an anti-corrosion boiler alcohol-based fuel, comprising the following steps:

[0047] 1) Mix methanol and ethanol evenly, add pine tar and paraffin oil, stir, and mix evenly;

[0048] 2) Add butyl titanate to the material obtained in step 1), stir and mix evenly;

[0049] 3) At room temperature, slowly add sodium carboxymethylcellulose into water heated to 40-42°C, add while stirring, mix evenly, and dissolve completely;

[0050] 4) Add the material obtained in step 2) to the material obtained in step 3), stir and mix evenly to obtain the product.

Embodiment 3

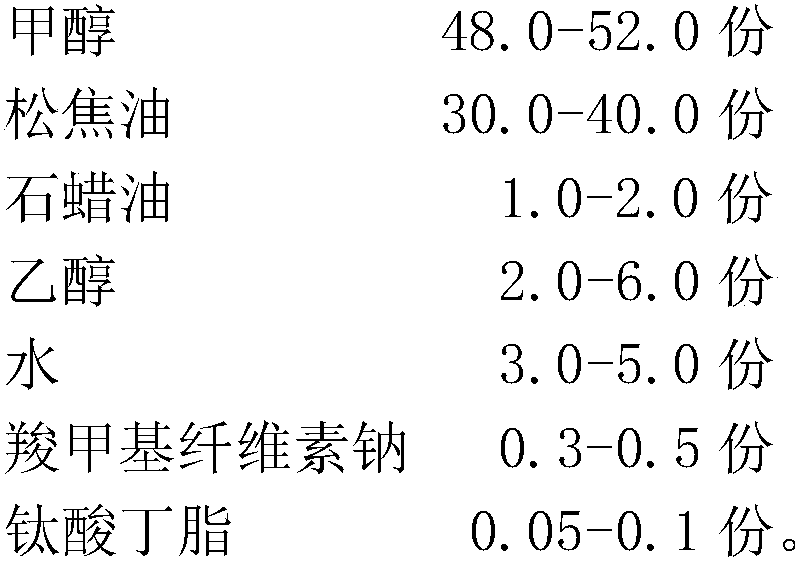

[0052] A corrosion-resistant boiler alcohol-based fuel consisting of the following ingredients by weight:

[0053]

[0054]

[0055] A method for preparing an anti-corrosion boiler alcohol-based fuel, comprising the following steps:

[0056] 1) Mix methanol and ethanol evenly, add pine tar and paraffin oil, stir, and mix evenly;

[0057] 2) Add butyl titanate to the material obtained in step 1), stir and mix evenly;

[0058] 3) At room temperature, slowly add sodium carboxymethylcellulose into water heated to 40-42°C, add while stirring, mix evenly, and dissolve completely;

[0059] 4) Add the material obtained in step 2) to the material obtained in step 3), stir and mix evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com