Textile fabric composite milk fiber and preparation method thereof

A technology of textile fabrics and milk fibers, which is applied in the field of textile fibers, can solve the problems of milk protein fibers such as antibacterial and lack of mechanical properties, and achieve the effect of improving spinning effect, good fiber mechanical properties, and good anti-ultraviolet properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

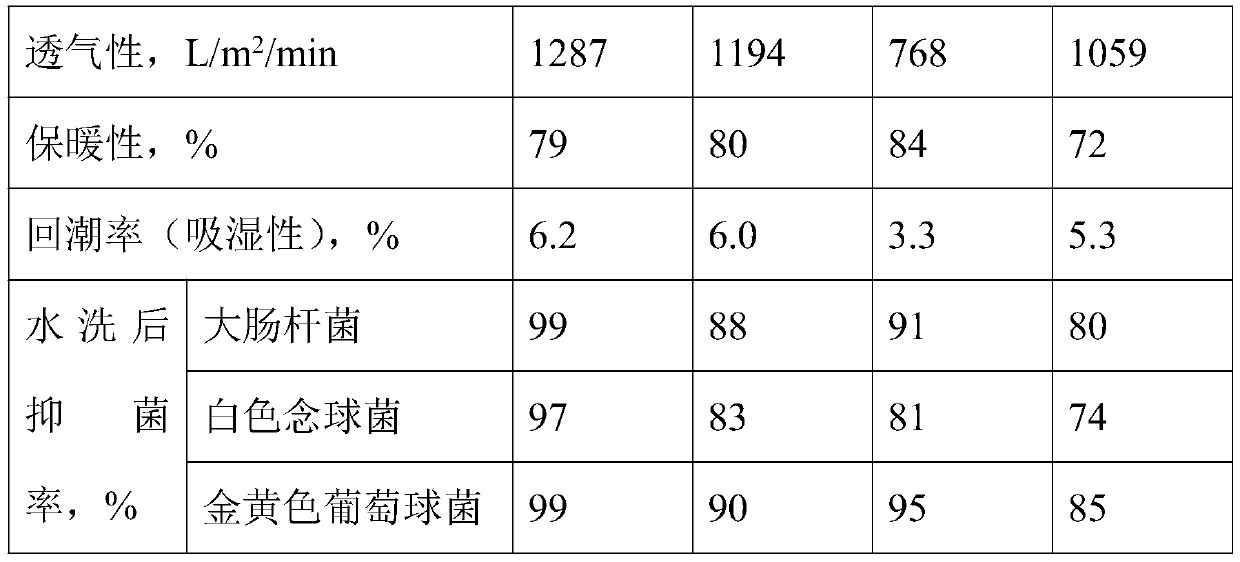

Examples

Embodiment 1

[0036] A preparation method for composite milk fiber for textile fabrics, comprising the steps of:

[0037] S1. Put 2kg chitosan, 0.6kg polyoxyethylene ether and propylene oxide block copolymer, 50kg N-methylmorpholine-N-oxide into the stirrer, stir for 10min at 18°C, and the stirring speed is 200r / min, add 10kg coarse staple cotton and stir 20min, stirring speed is 60r / min, obtains pretreated coarse staple cotton;

[0038] S2. Mix milk protein fiber and acetic acid solution with a concentration of 0.8mol / L at a mass ratio of 2:5 to obtain an acetic acid solution containing milk protein fiber;

[0039] Add 25kg of pretreated coarse cotton to 4kg of nano-silica with an average particle size of 180nm and ultrasonically treat it for 20min, the ultrasonic frequency is 60kHz, keep it warm for 20h, filter, dry, then add 60kg of acetic acid solution containing milk protein fibers, 4 Stir at low temperature for 1 hour, raise the temperature to 10°C and continue to stir for 15 minute...

Embodiment 2

[0047] A preparation method for composite milk fiber for textile fabrics, comprising the steps of:

[0048]S1. Put 4kg chitosan, 0.2kg polyvinyl alcohol, and 100kg N-methylmorpholine-N-oxide into the stirrer, stir for 20 minutes at 12°C, and the stirring speed is 100r / min, add 20kg coarse cotton and stir 10min, stirring speed is 80r / min, obtains pretreated thick staple cotton;

[0049] S2. Mix milk protein fiber and acetic acid solution with a concentration of 0.4mol / L at a mass ratio of 1:10 to obtain an acetic acid solution containing milk protein fiber;

[0050] Add 15kg of pretreated coarse cotton to 8kg of nano-silica with an average particle size of 200nm and ultrasonically treat it for 10min at an ultrasonic frequency of 100kHz, keep it warm for 10h, filter and dry, then add 120kg of acetic acid solution containing milk protein fibers, 1 Stir at low temperature for 2 hours, raise the temperature to 6°C and continue to stir for 25 minutes, raise the temperature to 25°C ...

Embodiment 3

[0058] A preparation method for composite milk fiber for textile fabrics, comprising the steps of:

[0059] S1. Put 2.5kg chitosan, 0.5kg alkylphenol polyoxyethylene ether, 60kg N-methylmorpholine-N-oxide into the mixer, stir at 16°C for 12min, the stirring speed is 170r / min, add 13kg coarse staple cotton stirred 17min, and stirring speed was 65r / min, obtained pretreated coarse staple cotton;

[0060] S2. Mix milk protein fiber and acetic acid solution with a concentration of 0.7mol / L in a mass ratio of 17:60 to obtain an acetic acid solution containing milk protein fiber;

[0061] Add 22kg of pretreated coarse cotton to 5kg of nano-silica with an average particle size of 160nm and ultrasonically treat it for 17min, the ultrasonic frequency is 70kHz, keep it warm for 17h, filter, dry, then add 80kg of acetic acid solution containing milk protein fiber, 3 Stir at low temperature for 1.3 hours, raise the temperature to 9°C and continue to stir for 18 minutes, raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com