PTT polyester with concentrated molecular weight distribution and preparation method thereof

A technology of molecular weight and polyester, which is applied in the field of chemical fiber processing, can solve problems such as end breakage and wool, and achieve the effects of avoiding deactivation, reducing time cost and capital cost, and improving PTT hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

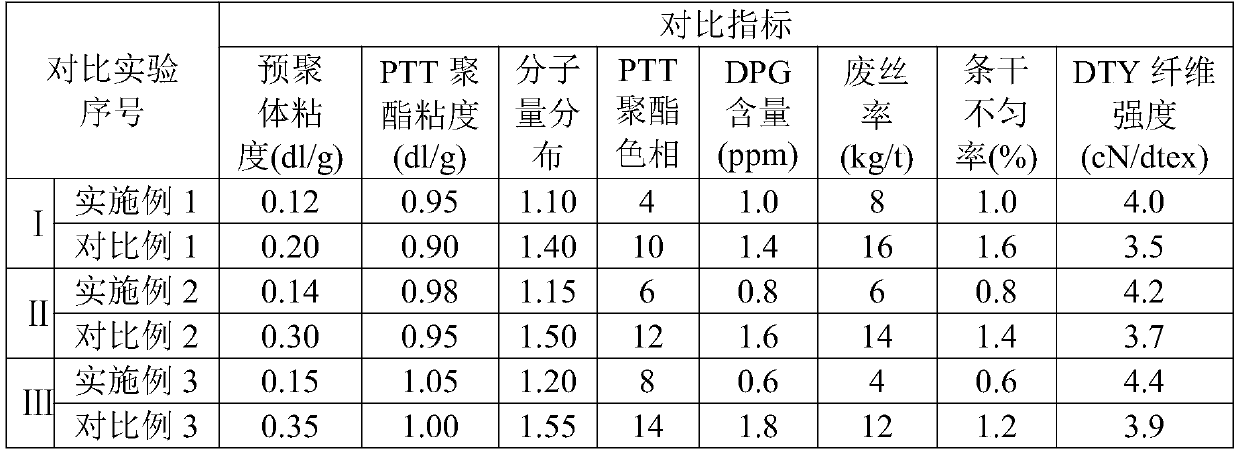

Examples

Embodiment 1

[0046] The present embodiment provides a kind of production method of the PTT polyester of concentrated molecular weight distribution, and it comprises the following steps:

[0047] (1) Preparation of PTT polyester prepolymer: mix terephthalic acid and 1,3-propanediol with a molar ratio of 1:1.1 for beating, and add titanium tin cobalt composite catalyst and anti-ether agent sodium acetate for esterification Reaction until the esterification water output reaches 95% of the theoretical esterification water output, the reactor pressure is released to normal pressure, and the reaction is continued for 15 minutes to obtain a PTT polyester prepolymer with low intrinsic viscosity;

[0048] Wherein, the titanium-tin-cobalt composite catalyst is composed of tetrabutyl titanate, dibutyltin oxide and cobalt acetate with a molar ratio of 1:0.5:0.5, and the addition amount of the titanium-tin-cobalt composite catalyst is terephthalic acid 100ppm of the mass fraction of (PTA); The addition...

Embodiment 2

[0059] The present embodiment provides a kind of production method of the PTT polyester of concentrated molecular weight distribution, and it comprises the following steps:

[0060] (1) Preparation of PTT polyester prepolymer: mix terephthalic acid and 1,3-propanediol in a molar ratio of 1:1.5 for beating, and add titanium tin cobalt composite catalyst and anti-ether agent sodium acetate for esterification Reaction until the esterification water output reaches 95% of the theoretical esterification water output, the reactor pressure is released to normal pressure, and the reaction is continued for 30 minutes to obtain a low intrinsic viscosity PTT polyester prepolymer;

[0061] Wherein, the titanium-tin-cobalt composite catalyst is composed of tetrabutyl titanate, indium tin oxide and cobalt acetate with a molar ratio of 1:0.5:0.5, and the addition amount of the titanium-tin-cobalt composite catalyst is terephthalic acid (PTA ) of the mass fraction of 150ppm; the addition of so...

Embodiment 3

[0071] The present embodiment provides a kind of production method of the PTT polyester of concentrated molecular weight distribution, and it comprises the following steps:

[0072] (1) Preparation of PTT polyester prepolymer: mix terephthalic acid and 1,3-propanediol with a molar ratio of 1:1.3 for beating, and add titanium tin cobalt composite catalyst and anti-ether agent sodium acetate for esterification Reaction, until the esterification water output reaches 95% of the theoretical esterification water output, the reactor pressure is released to normal pressure, and the reaction is continued for 35 minutes to obtain a low intrinsic viscosity PTT polyester prepolymer;

[0073] Among them, the titanium-tin-cobalt composite catalyst is composed of metatitanic acid, indium tin oxide and cobalt acetate in a molar ratio of 1:1:1, and the addition amount of the titanium-tin-cobalt composite catalyst is 1 / 4 of terephthalic acid (PTA). 150ppm of the mass fraction; the addition of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com