Preparation method and application of a molecularly imprinted composite membrane initiated by a surface functional monomer prepolymerization system

A molecular imprinting, functional monomer technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems such as large flow resistance, and achieve reduced non-specific adsorption, high adsorption selectivity, and fast adsorption kinetics The effect of academic nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

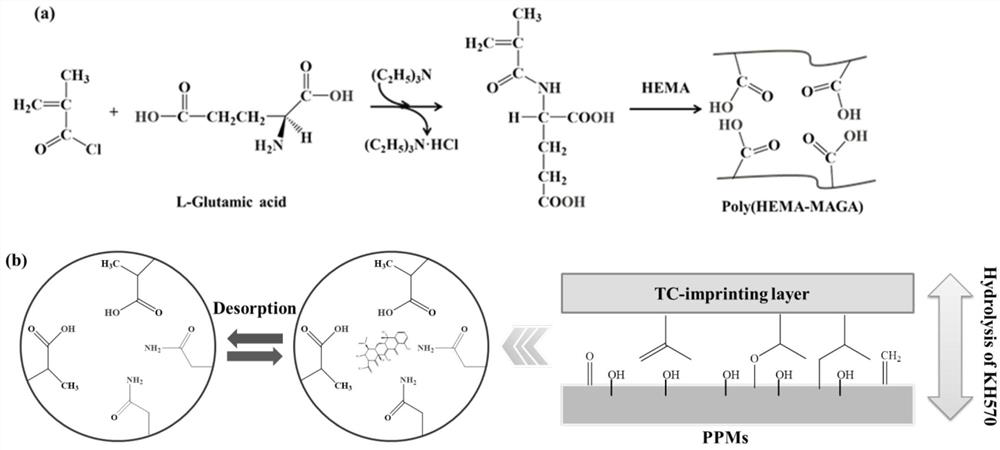

[0057] (1) Synthesis of 2-methacrylamide glutamic acid (MAGA);

[0058] First, add 5.0 g of glutamic acid and 0.2 g of hydroquinone to 100 mL of dichloromethane, and store at 0°C; then add nitrogen, add 13.0 g of triethylamine and 4.0 mL of methacryloyl chloride, and stir magnetically at room temperature for 2 h; After the end, add 1.3g NaOH, and evaporate the water phase in the solution through a rotary evaporator; put the residue in a vacuum oven at 60°C for 24 hours; obtain a dry product, which is MAGA; dissolve 10g of MAGA in 40mL of ethanol , stored for later use;

[0059] (2) Preparation of poly(HEMA-MAGA) particles;

[0060] Mix 0.5g of benzoyl peroxide, 0.5g of polypropylene alcohol, 10mL of hydroxyethyl methacrylate (HEMA) and 0.5g of MAGA for copolymerization reaction. The temperature of the copolymerization reaction is 40°C and the reaction time is 24h ; After the reaction, filter and wash, dry in a vacuum oven, and grind after drying to obtain poly(HEMA-MAGA) par...

Embodiment 2

[0078] (1) Synthesis of 2-methacrylamide glutamic acid (MAGA);

[0079]First, add 5.0 g of glutamic acid and 0.2 g of hydroquinone to 100 mL of dichloromethane, and store at 0°C. Then nitrogen was added, 13.0 g of triethylamine and 4.0 mL of methacryloyl chloride were added, and magnetically stirred at room temperature for 2 h. After the reaction was completed, 1.3 g of NaOH was added, and the water phase in the solution was evaporated by a rotary evaporator. The residue was placed in a vacuum oven at 60°C for 36 hours. 10 g of MAGA was then dissolved in 40 mL of ethanol and stored for later use;

[0080] (2) Preparation of poly(HEMA-MAGA) particles;

[0081] Mix 0.5g of benzoyl peroxide, 0.5g of polypropylene alcohol, 10mL of hydroxyethyl methacrylate (HEMA) and 0.5g of MAGA for copolymerization reaction. The temperature of the copolymerization reaction is 40°C and the reaction time is 24h ; After the reaction, filter and wash, dry in a vacuum oven, and grind after drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com