A high ductility electrolytic copper foil and its preparation method

An electrolytic copper foil, ductility technology, applied in the electrolytic process, electroforming, coating and other directions, can solve the problems of poor copper foil ductility, affecting the yield of copper foil, residual organic impurities, etc., to achieve both anti-oxidation ability , Easy to store for a long time, the surface is not rough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

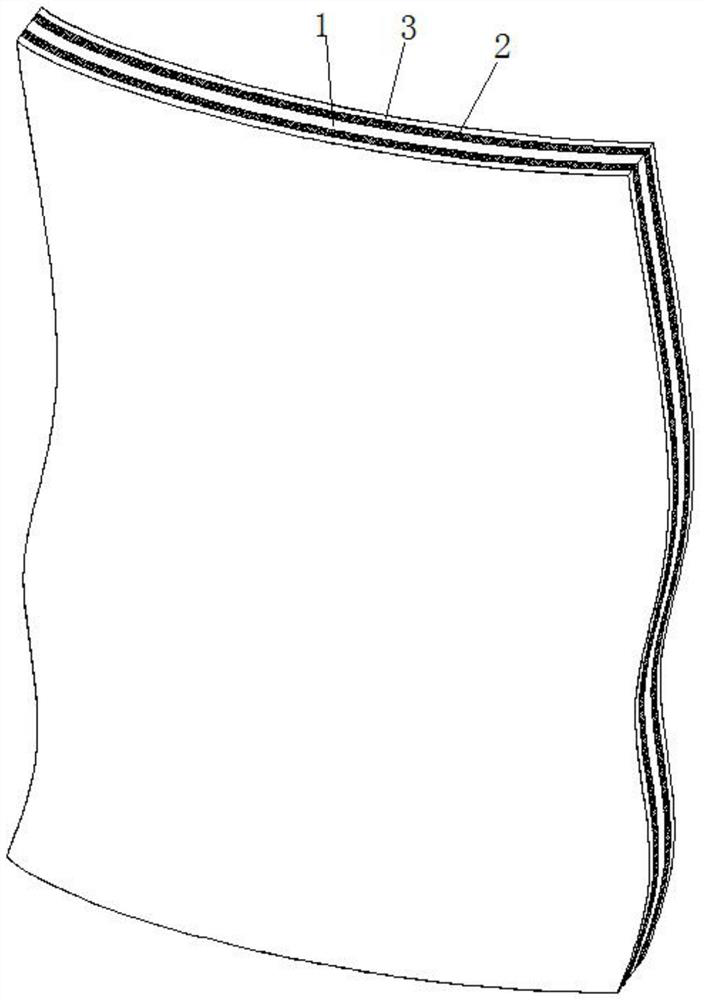

[0028] according to figure 1 As shown, a high-ductility electrolytic copper foil includes a raw foil 1, a barrier layer 2 and an anti-oxidation coating 3. The surface of the raw foil 1 is a roughened surface, and a barrier layer 2 is provided on the roughened surface. The barrier layer 2 is externally coated with an anti-oxidation coating 3 .

[0029] The thickness of the raw foil 1 is 50 μm, and the arithmetic mean value Ra of roughness of the rough surface of the raw foil 1 is 0.6 μm.

[0030] The barrier layer 2 is zinc particles.

[0031] The anti-oxidation coating 3 is a chromate solution.

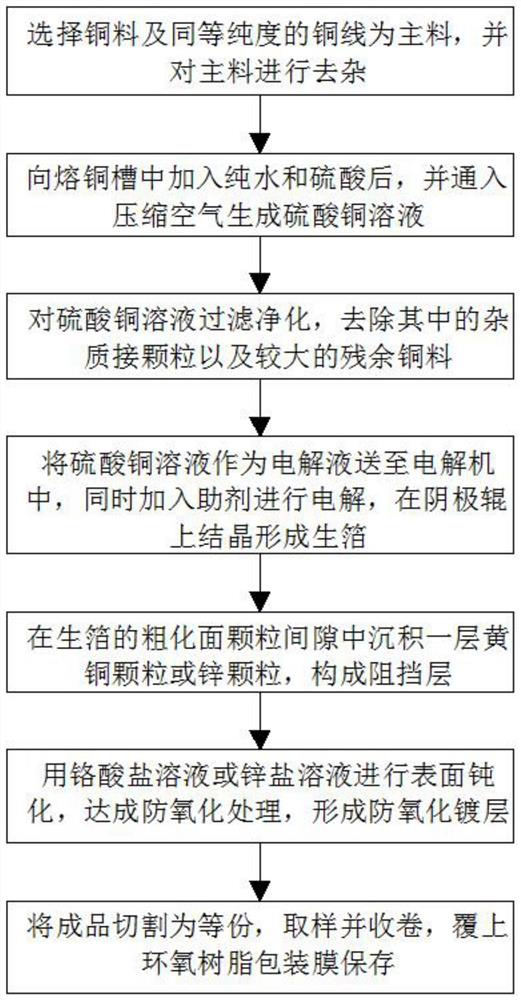

[0032] according to figure 2 Shown, a kind of preparation method of high ductility electrolytic copper foil, comprises the following steps:

[0033] Step 1: Select copper material and copper wire of the same purity as the main material. The purity of the main material is greater than 99.8%. First, remove the impurities from the main material. The specific operation is annealing t...

Embodiment 2

[0041] according to figure 1 As shown, a high-ductility electrolytic copper foil includes a raw foil 1, a barrier layer 2 and an anti-oxidation coating 3. The surface of the raw foil 1 is a roughened surface, and a barrier layer 2 is provided on the roughened surface. The barrier layer 2 is externally coated with an anti-oxidation coating 3 .

[0042] The thickness of the raw foil 1 is 50 μm, and the arithmetic mean value Ra of roughness of the rough surface of the raw foil 1 is 0.6 μm.

[0043] The barrier layer 2 is zinc particles.

[0044] The anti-oxidation coating 3 is zinc salt solution.

[0045] according to figure 2 Shown, a kind of preparation method of high ductility electrolytic copper foil, comprises the following steps:

[0046] Step 1: Select copper material and copper wire of the same purity as the main material. The purity of the main material is greater than 99.8%. First, remove the impurities from the main material. The specific operation is annealing to...

Embodiment 3

[0054] according to figure 1 As shown, a high-ductility electrolytic copper foil includes a raw foil 1, a barrier layer 2 and an anti-oxidation coating 3. The surface of the raw foil 1 is a roughened surface, and a barrier layer 2 is provided on the roughened surface. The barrier layer 2 is externally coated with an anti-oxidation coating 3 .

[0055] The thickness of the raw foil 1 is 50 μm, and the arithmetic mean value Ra of roughness of the rough surface of the raw foil 1 is 0.6 μm.

[0056] The barrier layer 2 is brass particles.

[0057] The anti-oxidation coating 3 is a chromate solution.

[0058] according to figure 2 Shown, a kind of preparation method of high ductility electrolytic copper foil, comprises the following steps:

[0059] Step 1: Select copper material and copper wire of the same purity as the main material. The purity of the main material is greater than 99.8%. First, remove the impurities from the main material. The specific operation is annealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com