Solid-state battery and preparation method thereof, and electric vehicle

A technology of solid-state batteries and solid-state electrolytes, which is applied in battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., and can solve problems such as increased grain boundary resistance, low compaction density, and short-circuiting of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The second purpose of the present application is to provide a method for preparing a solid-state battery, the method comprising:

[0062] S1. Provide a positive electrode layer, the positive electrode layer includes a positive electrode current collector and a positive electrode active material layer located on the surface of the positive electrode current collector, the positive electrode active material layer includes positive electrode active particles and first solid electrolyte particles; heating the positive electrode layer to make The first solid electrolyte particles in the positive electrode layer are completely melted;

[0063] S2. Provide a composite layer, the composite layer includes a negative electrode current collector and a solid electrolyte layer located on the surface of the negative electrode current collector, the solid electrolyte layer includes second solid electrolyte particles; heating the composite layer makes the second solid electrolyte layer ...

Embodiment 1

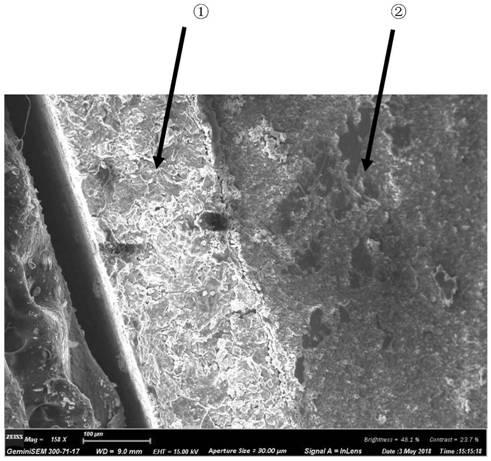

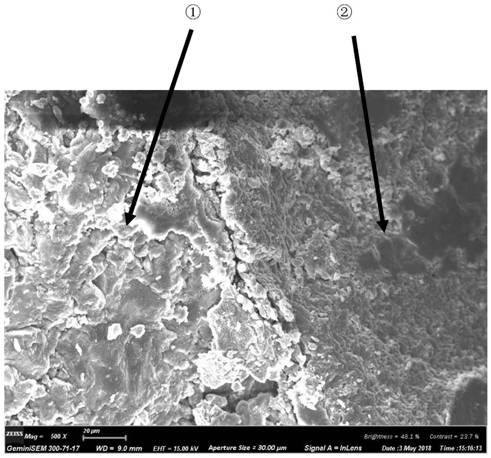

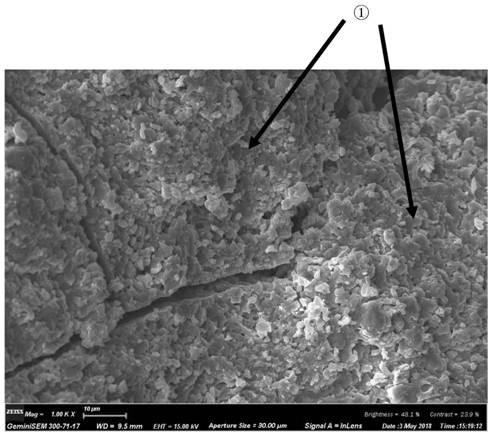

[0078] (1) Fabrication of composite layer of negative electrode A and solid electrolyte E

[0079] The composition percentage of the solid electrolyte described in this example is as follows: with 75Li 2 S-25P 2 S 5 as an example.

[0080] The production process is as follows: in a glove box with an argon atmosphere, the stoichiometric ratio of Li 2 S (7.03g), P 2 S 5 (11.33g) was mixed and added to a 50ml sealed ball mill jar for 500rpm ball milling for 8h, then taken out and ground into powder, and put into 50g of toluene solution, and then heated and stirred the solid electrolyte slurry. The solid electrolyte slurry was continuously coated on the negative electrode current collector A with a coating thickness of 70 μm and dried at 333 K to obtain a composite EA, which was cut into a size of 100 mm (length) × 100 mm (width). The good EA was placed on a hot plate and heated to 700°C to melt and spread for 30 minutes, and set aside for later use.

[0081] (2) Production...

Embodiment 2

[0086] The solid-state battery was prepared by the same method as in Example 1, except that in step (1), the heating time of EA was 20 min, and in step (2), the heating time was 10 min, and the obtained battery was denoted as S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volumetric energy density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com