Freeze-drying method of HM-3 freeze-dried preparation for injection

A technology for freeze-dried preparations and injections, applied in the field of freeze-dried antiangitide freeze-dried preparations for injection, can solve problems such as unevenness, increased production costs, shrinkage, etc., achieve stable properties and biological activities, and improve product integrity The effect of high degree and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

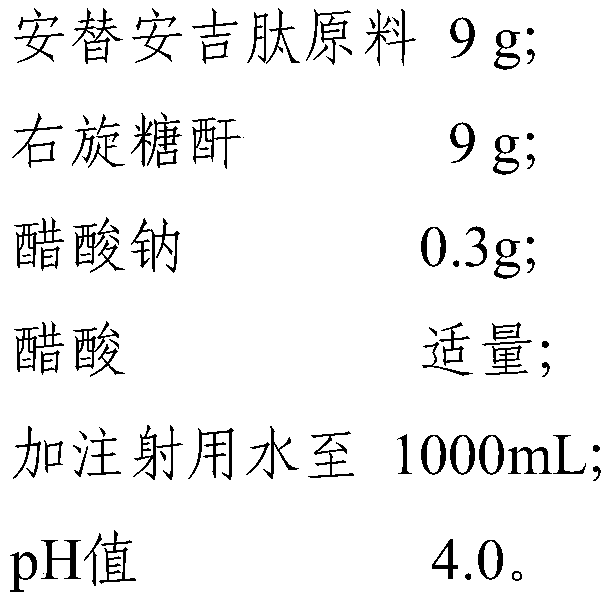

[0048] This embodiment provides a freeze-drying method of antiangitide lyophilized preparation for injection, the prescription of the antiangitide lyophilized preparation for injection is as follows:

[0049]

[0050] The preparation steps of the antiangitide freeze-dried preparation for injection are as follows:

[0051] First prepare the solution, add the HM-3 polypeptide raw material to 400mL water for injection to make a solution, filter it with a 0.22μm membrane aseptically for use, and obtain the polypeptide solution;

[0052] Weigh the excipients dextran and sodium acetate and add them to 400mL water for injection to form a solution, add activated carbon for needles, heat and filter, decarbonize, and filter with a 0.22μm membrane to make a pyrogen-free sterile excipient aqueous solution, and cool;

[0053] Mix the polypeptide solution and the excipient solution, add an appropriate amount of acetic acid to make the pH of the solution 4.0; add water for injection to 10...

Embodiment 2

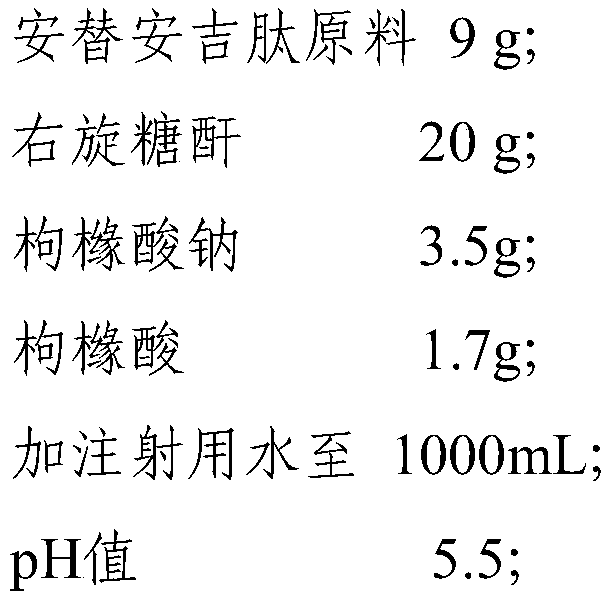

[0065] This embodiment provides a freeze-drying method of antiangitide lyophilized preparation for injection, and the prescription of antiangitide lyophilized preparation for injection is as follows:

[0066]

[0067] The preparation steps of the antiangitide freeze-dried preparation for injection are as follows:

[0068] First prepare the solution, add the HM-3 polypeptide raw material to 400mL water for injection to make a solution, filter it with a 0.22μm membrane aseptically for use, and obtain the polypeptide solution;

[0069] Weigh the excipients dextran, citric acid and sodium citrate and add them to 400mL water for injection to form a solution, add activated carbon for needles, heat and filter, decarbonize, and filter with a 0.22 μm membrane to make a pyrogen-free sterile excipient aqueous solution, and cool;

[0070] Mix the peptide solution and the excipient solution, add water for injection to 1000mL, put the mixed solution into a clean and sterile vial, batch 1...

Embodiment 3

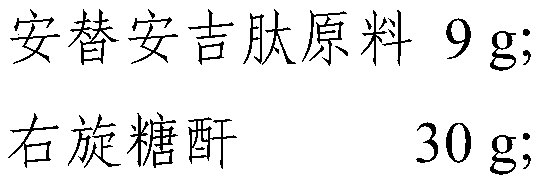

[0084] This embodiment provides a freeze-drying method of antiangitide lyophilized preparation for injection, and the prescription of antiangitide lyophilized preparation for injection is as follows:

[0085]

[0086]

[0087] The preparation steps of the antiangitide freeze-dried preparation for injection are as follows:

[0088] First prepare the solution, add the HM-3 polypeptide raw material to 400mL water for injection to make a solution, filter it with a 0.22μm membrane aseptically for use, and obtain the polypeptide solution;

[0089] Weigh the excipients dextran, disodium hydrogen phosphate and sodium dihydrogen phosphate and add them to 400mL water for injection to make a solution, add activated carbon for needles, heat and filter, decarbonize, filter with a 0.22μm membrane to make a pyrogen-free sterile excipient aqueous solution, cool ;

[0090] Mix the peptide solution and the excipient solution, add water for injection to 1000mL, put the mixed solution into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com