1, 2-cyclohexanediamine tetraacetic acid and purification method thereof

A technology of cyclohexanediaminetetraacetic acid and purification method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low removal rate of metal ions, difficult removal of metal ions, and difficult purification operations, etc., Achieve the effect of low purification cost, meet mass production requirements, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

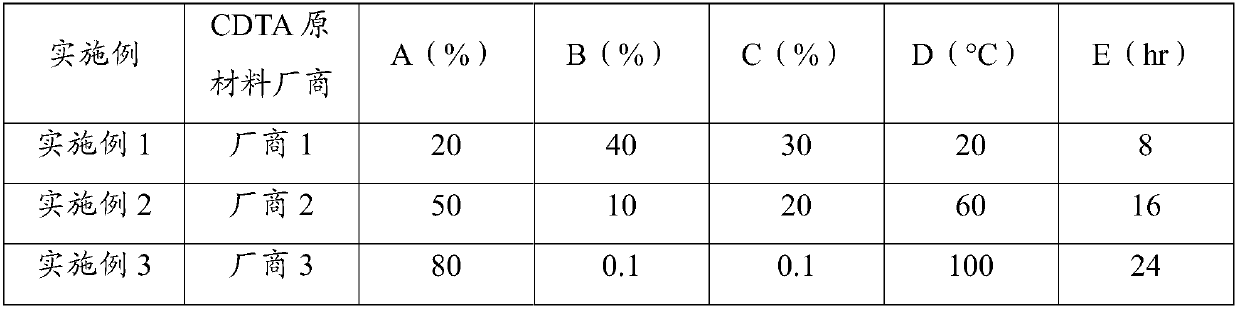

[0037] A method for purifying 1,2-cyclohexanediaminetetraacetic acid (CDTA) of the present invention comprises the following steps:

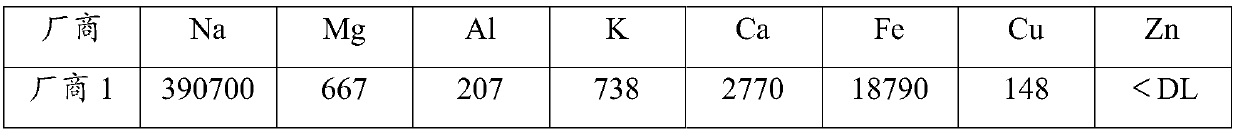

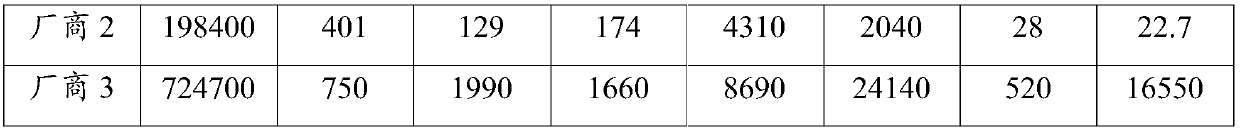

[0038] Step 1, select the CDTA raw material of the manufacturer shown in Table 1, add the medium whose mass percent concentration is A, then add the alkaline pH regulator whose mass percent concentration is B to it, make it dissolve in an alkaline environment, and be formulated into CDTA alkaline solution;

[0039] Step 2, adding a slightly excess acidic pH regulator with a mass percentage concentration of C to the CDTA solution obtained in step 1 to make the solution acidic so that CDTA is completely precipitated;

[0040] Step 3, stand until layering, CDTA is completely precipitated, the upper layer liquid is poured out, and the CDTA filter cake is filtered out;

[0041] Step 4. The CDTA filter cake is placed in a vacuum drying oven with a temperature of D, and dried under reduced pressure for E hours to form a dry and pure high-purity electr...

Embodiment 4~12

[0051]Select the CDTA raw materials of the same manufacturer, use different media, alkaline pH regulators, and acidic pH regulators respectively, purify CDTA according to the purification method of the present invention, and test the concentrations of sodium ions, calcium ions, and iron ions by ICP-OES spectrometer. , the above-mentioned metal ion concentration data before and after treatment are shown in Table 4.

[0052] Table 4 Contrast data of each metal ion concentration before and after treatment by different purification methods

[0053]

[0054] As can be seen from Table 4, using the purification method of the present invention to purify the CDTA raw material of the same manufacturer, the sodium ion, calcium ion, The content of main metal ions such as iron ions is reduced to less than 1ppm, and the removal rate of sodium ions is higher than 99%, the removal rate of calcium ions is higher than 64%, and the removal rate of iron ions is higher than 94%; As a medium, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com