Synthetic method of intermediate diacetyl ferrocene

A technology of bisacetylferrocene and synthesis method, applied in chemical instruments and methods, metallocenes, catalysts for physical/chemical processes, etc., can solve the problems of difficult control of reaction conditions, unsatisfactory yield, mild reaction conditions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

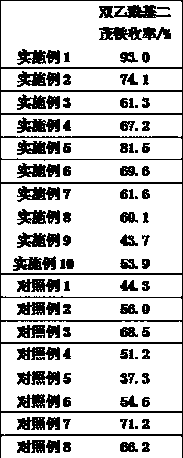

Examples

Embodiment 1

[0019] 1, a kind of synthetic method of intermediate bisacetyl ferrocene, it is characterized in that the method comprises the following steps:

[0020] Step 1. Dissolve 4g of ferrocene and 5g of acetic anhydride in 80ml of toluene in a four-necked flask. After fully dissolving, transfer it to a supercritical device, and feed supercritical carbon dioxide fluid into it, slowly at a rate of 0.5°C / min Heat up, add 8g AlCl 3 The loaded A1-MCM-41 catalyst was stirred at a constant temperature of 40°C and 7.5MPa for 5min;

[0021] Step 2. Add 30ml of chloroform under ultrasonic vibration conditions to make the catalyst fully dispersed and dissolved, and the reactor is connected to a tail gas absorption device that can prevent sucking back;

[0022] Step 3. Continue to feed supercritical carbon dioxide fluid into the reaction device, keep it at 0°C and 7.5Mpa, and the solution will turn blood red after 15 minutes, and the acetylation reaction will be completed when the solution turn...

Embodiment 2

[0033] Step 1. Dissolve 3g of ferrocene and 5g of acetic anhydride in 80ml of toluene in a four-neck flask. After fully dissolving, transfer it to a supercritical device, and feed supercritical carbon dioxide fluid into it, slowly at a rate of 0.5°C / min Heat up, add 8g AlCl 3 The supported A1-MCM-41 catalyst was stirred at a constant temperature of 40° C. and 7.5 MPa for 5 minutes; the rest of the steps were the same as in Example 1.

Embodiment 3

[0035] Step 1. Dissolve 2g of ferrocene and 5g of acetic anhydride in 80ml of toluene in a four-neck flask. After fully dissolving, transfer it to a supercritical device and feed supercritical carbon dioxide fluid. Slowly Heat up, add 8g AlCl 3 The supported A1-MCM-41 catalyst was stirred at a constant temperature of 40° C. and 7.5 MPa for 5 minutes; the rest of the steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com