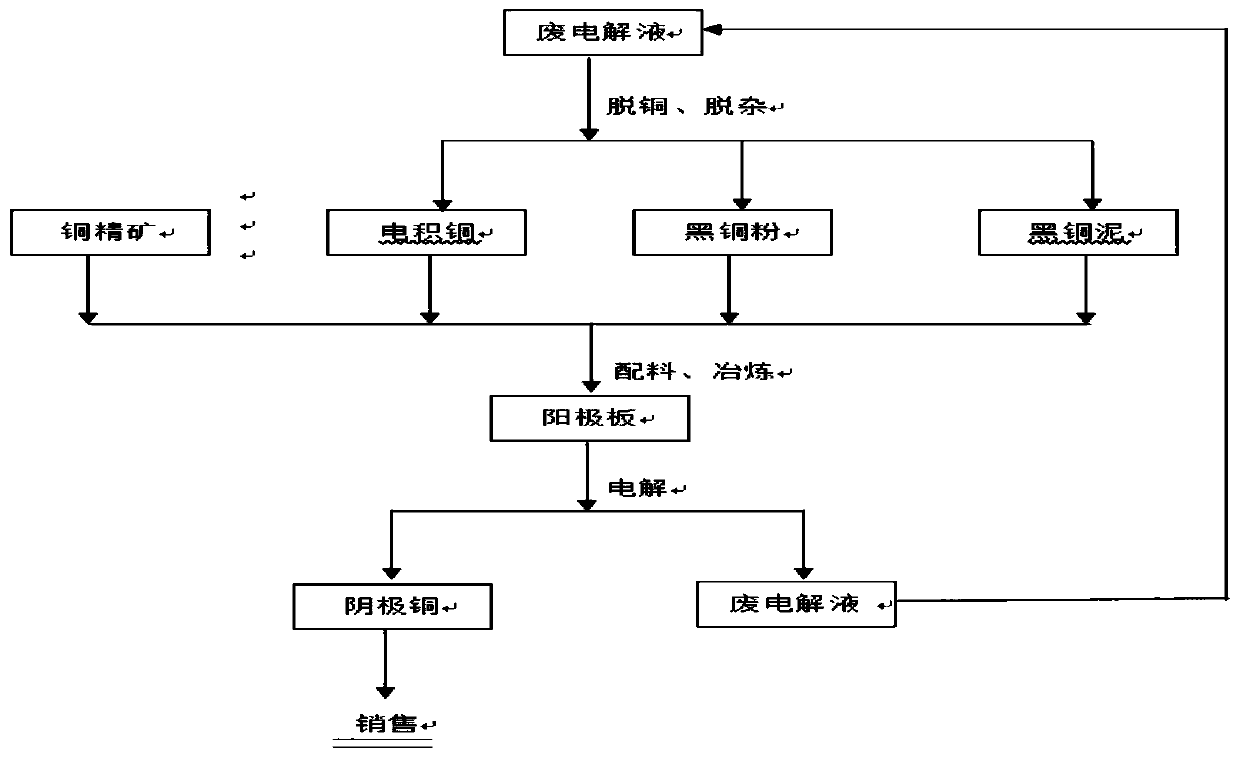

5N high-purity copper production method

A production method and high-purity copper technology, applied in the field of electrolytic copper, can solve the problems of large acid mist, rising copper ion concentration, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

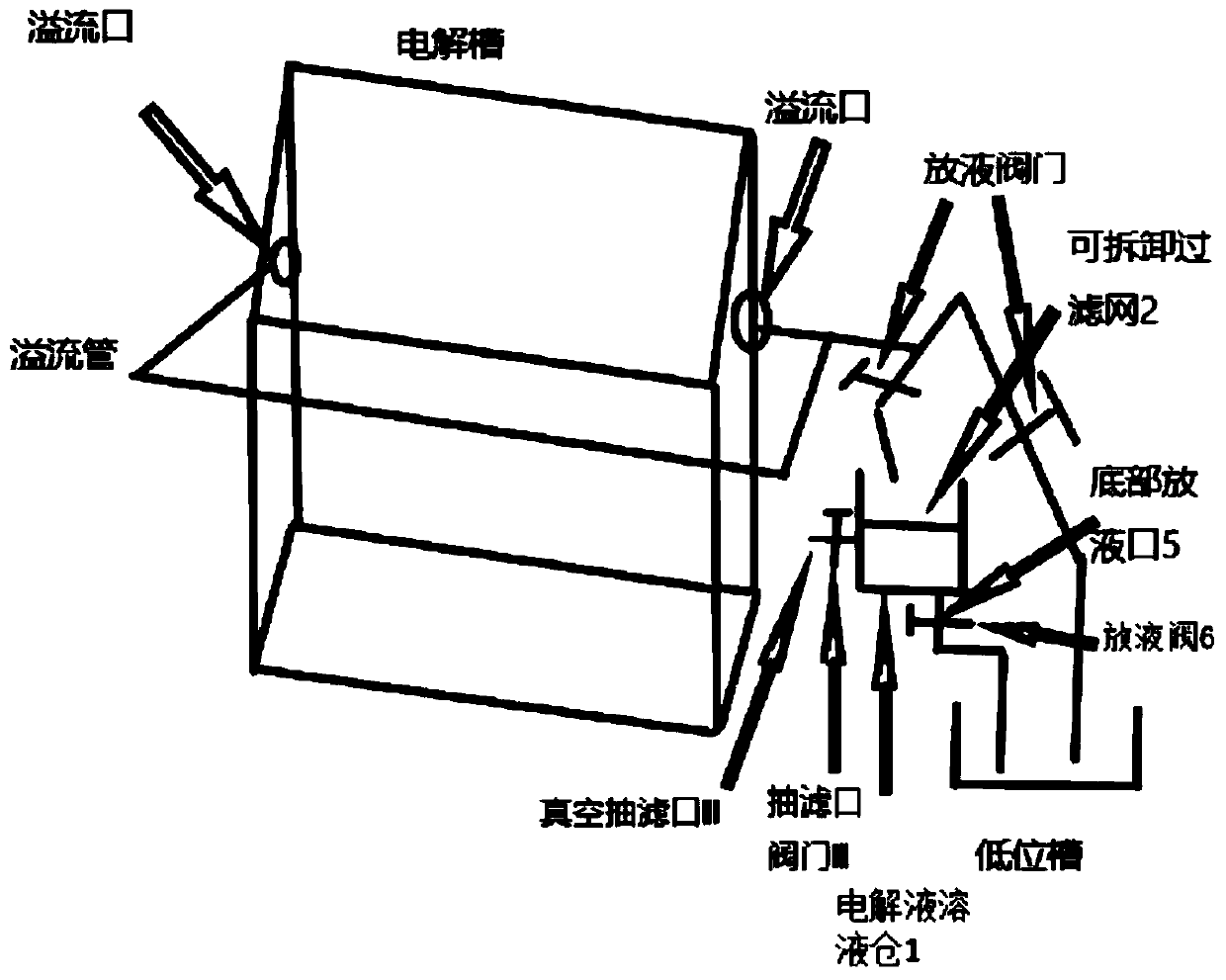

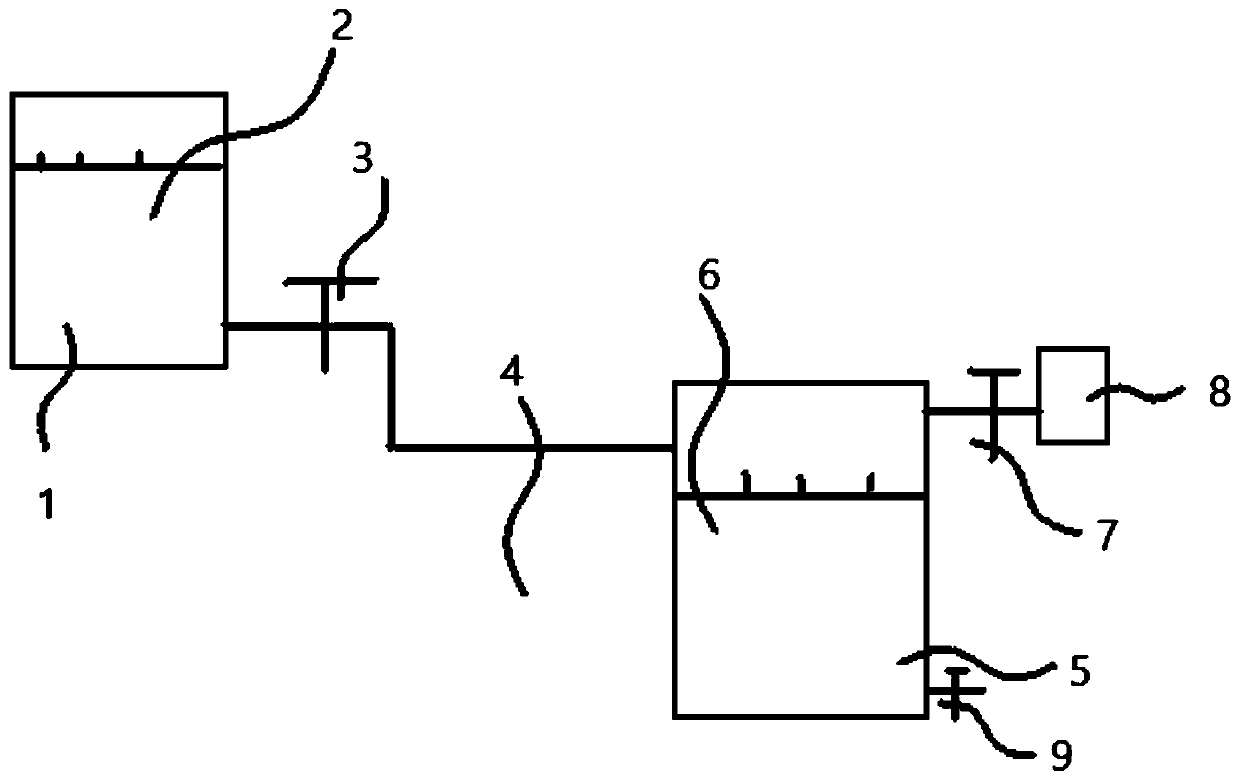

Method used

Image

Examples

Embodiment 1

[0045] (1) Process the copper-containing 99.93% electrodeposited copper produced by the treatment of waste electrolyte into an anode plate that meets the electrolytic size requirements, wrap it with a 400-mesh filter bag as the anode, and use a titanium plate as the cathode;

[0046] (2) With 99.5% Cu(NO 3 ) 2 ·3H 2 O, analytical pure nitric acid configuration contains copper 65g / L, contains the electrolytic solution of acid 16.4g / L;

[0047] (3) After the cathode and anode are installed in the tank, add 20ppm bone glue and 48mg / L hydrochloric acid. After 36 hours of circulation, power on and electrolyze for 72 hours, with a current density of 151A / m 2 ;The electrolyte temperature is 21°C (room temperature) before electrification, and the electrolyte temperature is maintained at 37.4-38.6°C after electrification for 3 hours;

[0048] (4) After electrification, add bone glue 50g / t in the first 24h; add bone glue 45g / t in 25~48h; add bone glue 40g / t in 49~72h;

[0049] (5) C...

Embodiment 2

[0060] (1) Process the copper-containing 99.9% electrodeposited copper produced by the treatment of waste electrolyte into an anode plate that meets the electrolytic size requirements, wrap it with a 300-mesh filter bag as the anode, and use a titanium plate as the cathode;

[0061] (2) With 99.5% Cu(NO 3 ) 2 ·3H 2 O, analytical pure nitric acid is configured to contain copper 75g / L, the electrolytic solution containing acid 18g / L;

[0062] (3) After the cathode and anode are installed in the tank, add 20ppm bone glue and 48mg / L hydrochloric acid. After 36 hours of circulation, power on and electrolyze for 72 hours, with a current density of 151A / m 2 ;The electrolyte temperature is 21°C (room temperature) before electrification, and the electrolyte temperature is maintained at 37-39°C after electrification for 3 hours;

[0063] (4) After electrification, add bone glue 60g / t in the first 24h; 25~48h, add bone glue 55g / t; 49~72h, add bone glue 50g / t;

[0064] (5) Calculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com